Hanger shaft installation workbench for brake lever hanger

A braking lever and worktable technology, which is applied to manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inability to ensure the installation accuracy of the hanger shaft 16, affecting the assembly of parts, etc., and achieves easy measurement, high installation accuracy, Easy to fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

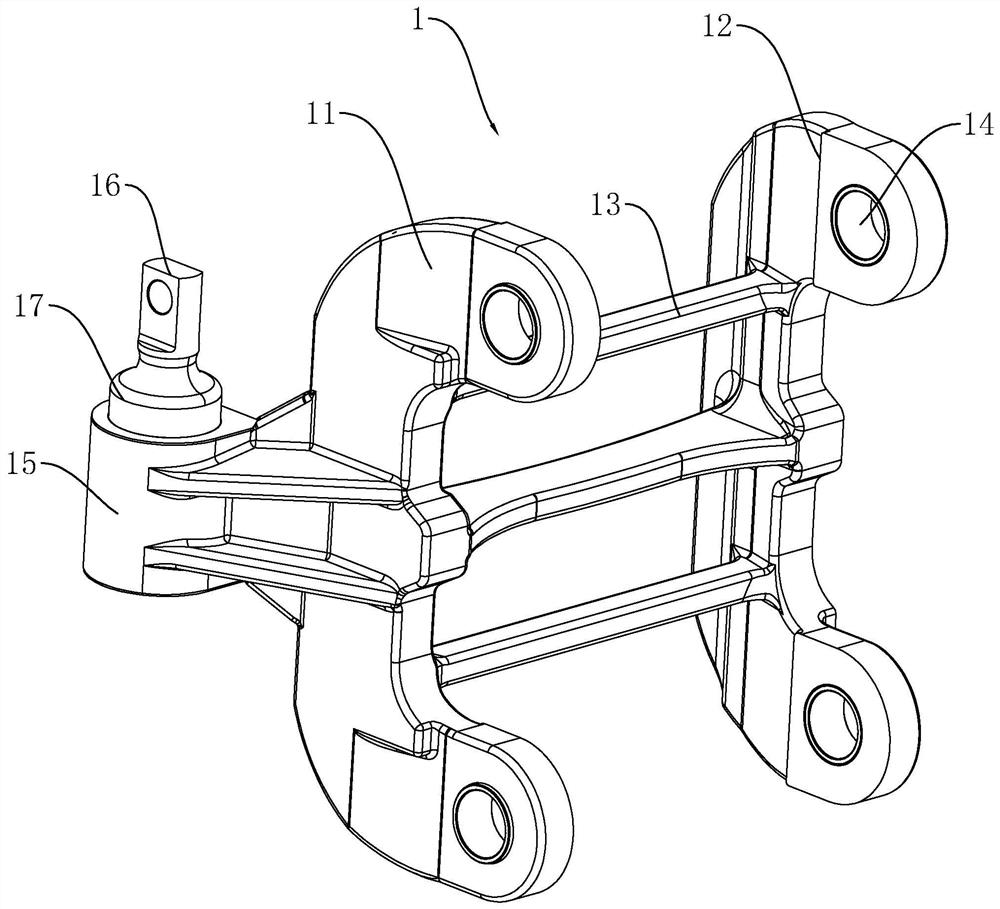

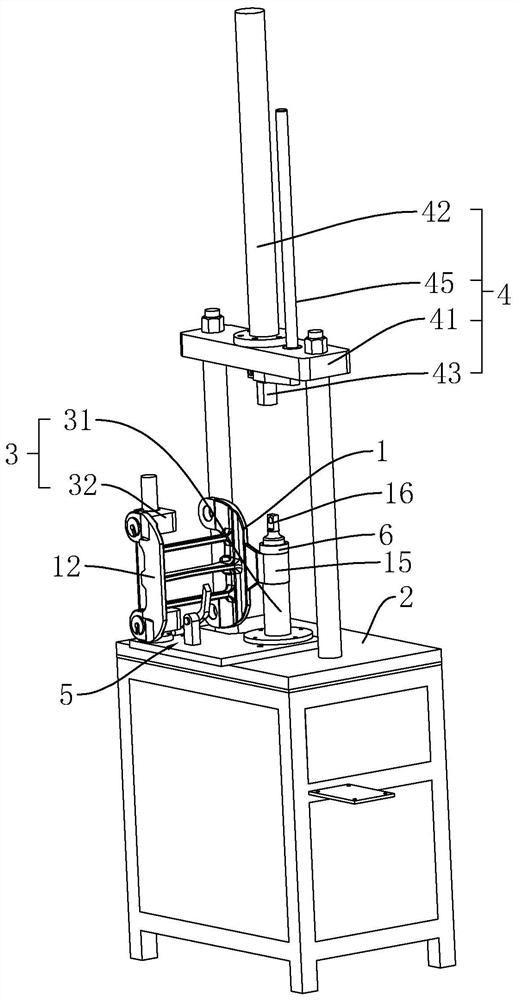

[0042] refer to figure 2 , is a hanger shaft installation workbench of a brake lever hanger disclosed by the present invention, including a workbench 2, on which a fixing device 3 for fixing the hanger 1 and a hanger shaft 16 for fixing the hanger shaft 1 are fixed. Install the hydraulic device 4 in the hoisting tube 15 on the suspension base 1.

[0043]The fixing device 3 includes a support tube 31 fixedly arranged on the top surface of the workbench 2 and a support frame 32 fixed on the workbench 2 for fixing the suspension seat 1. The support tube 31 is used to support the hoisting tube 15, and the support frame 32 and the The second connecting plate 12 cooperates to fix the suspension base 1 on the workbench 2 .

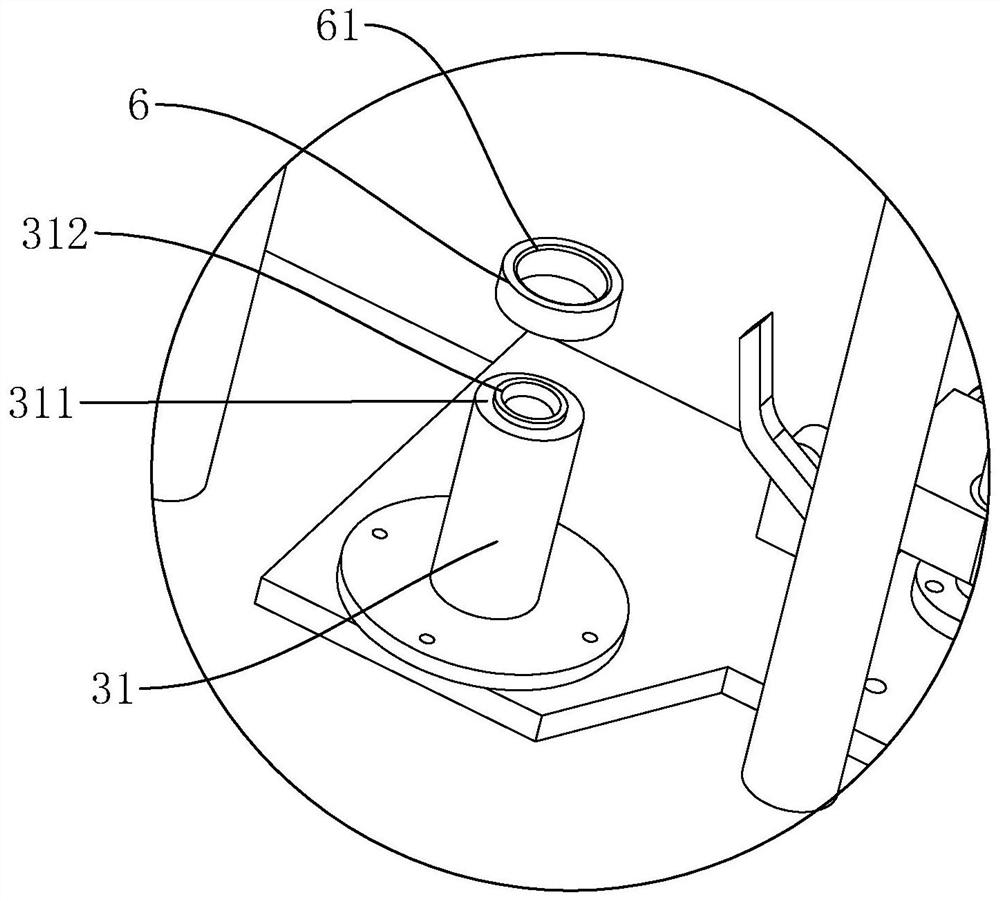

[0044] refer to image 3 , the upper end of the support tube 31 extends toward the central axis of the support tube 31 to form a support ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com