Tunnel track laying machine and hydraulic cylinder support arm for track laying machine

A technology of track laying machine and hydraulic cylinder, which is applied to roads, tracks, laying tracks, etc., and can solve problems such as stagnation of track paving process, impact on project progress, and narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

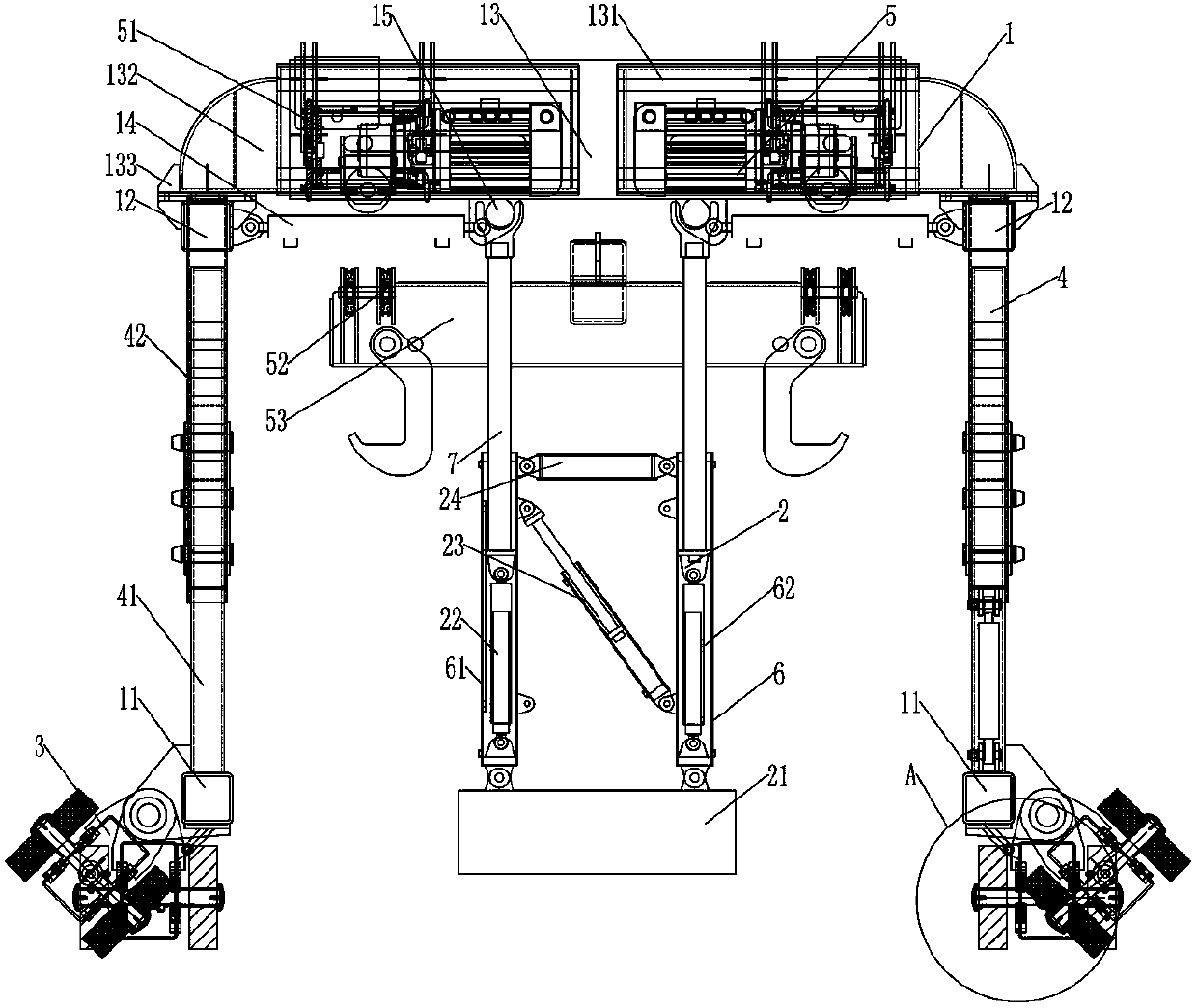

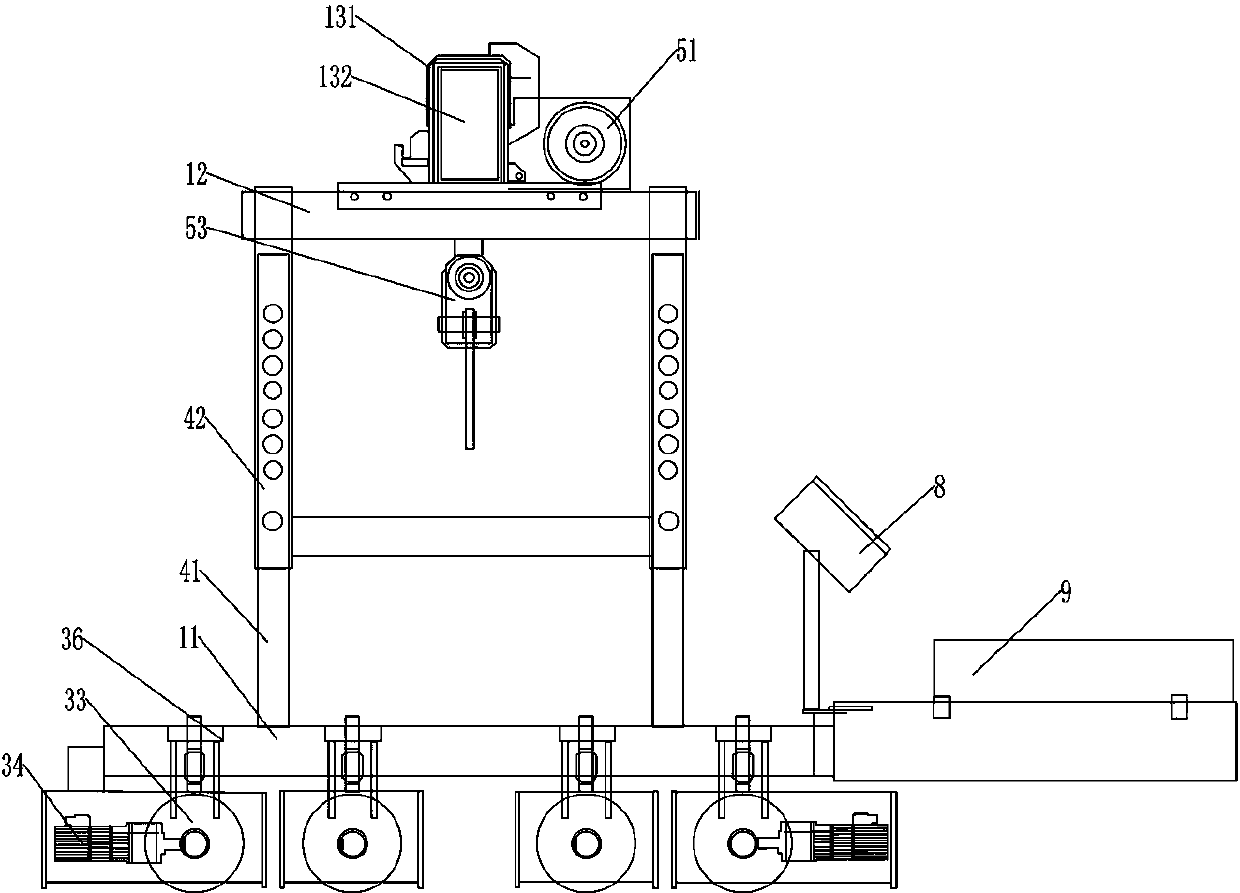

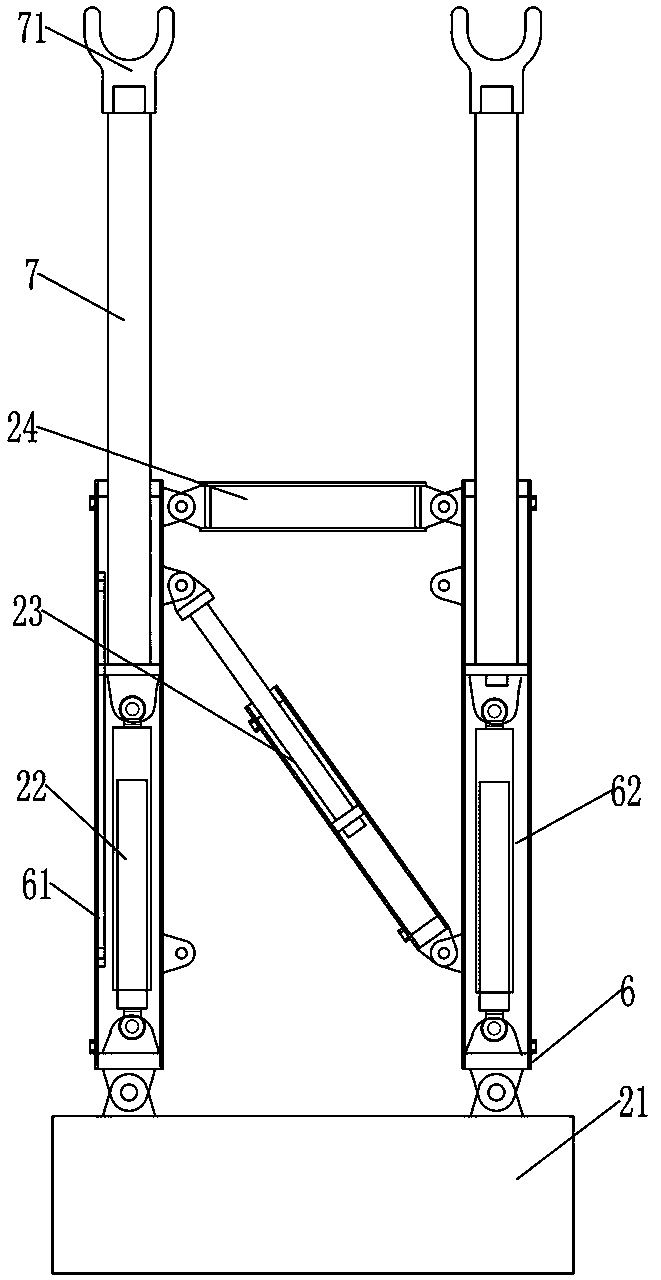

[0020] Such as Figure 1-6 As shown, a tunnel track-laying machine and a hydraulic cylinder support arm for a track-laying machine include a hydraulic cylinder support arm 2 for a tunnel track-laying machine 1 and an auxiliary track-laying machine. The bottom ends of the two ends of the beam 11 are respectively provided with a traveling mechanism 3, and the traveling mechanism 3 includes a traveling wheel support 31, and the traveling wheel support 31 is provided with a bearing, and the traveling wheel support 31 is connected with a transmission shaft 32 through the bearing rotation, and the transmission The shaft 32 is rotatable relative to the road wheel bracket 31 . The two ends of the transmission shaft 32 extend out of the road wheel bracket 31 respectively, and the two ends of the transmission shaft 32 are respectively fixed with a road wheel 33, and the outer side of the road wheel bracket 31 is fixed with a frequency conversion motor 34, and the transmission output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com