Quick-change machine tool bracket for engineering vehicle

A technology for engineering vehicles and implements, which is applied in the directions of earthmovers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of low efficiency and extrusion of connecting work implements, and reduce the quick change of implements. time, reduce manufacturing costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

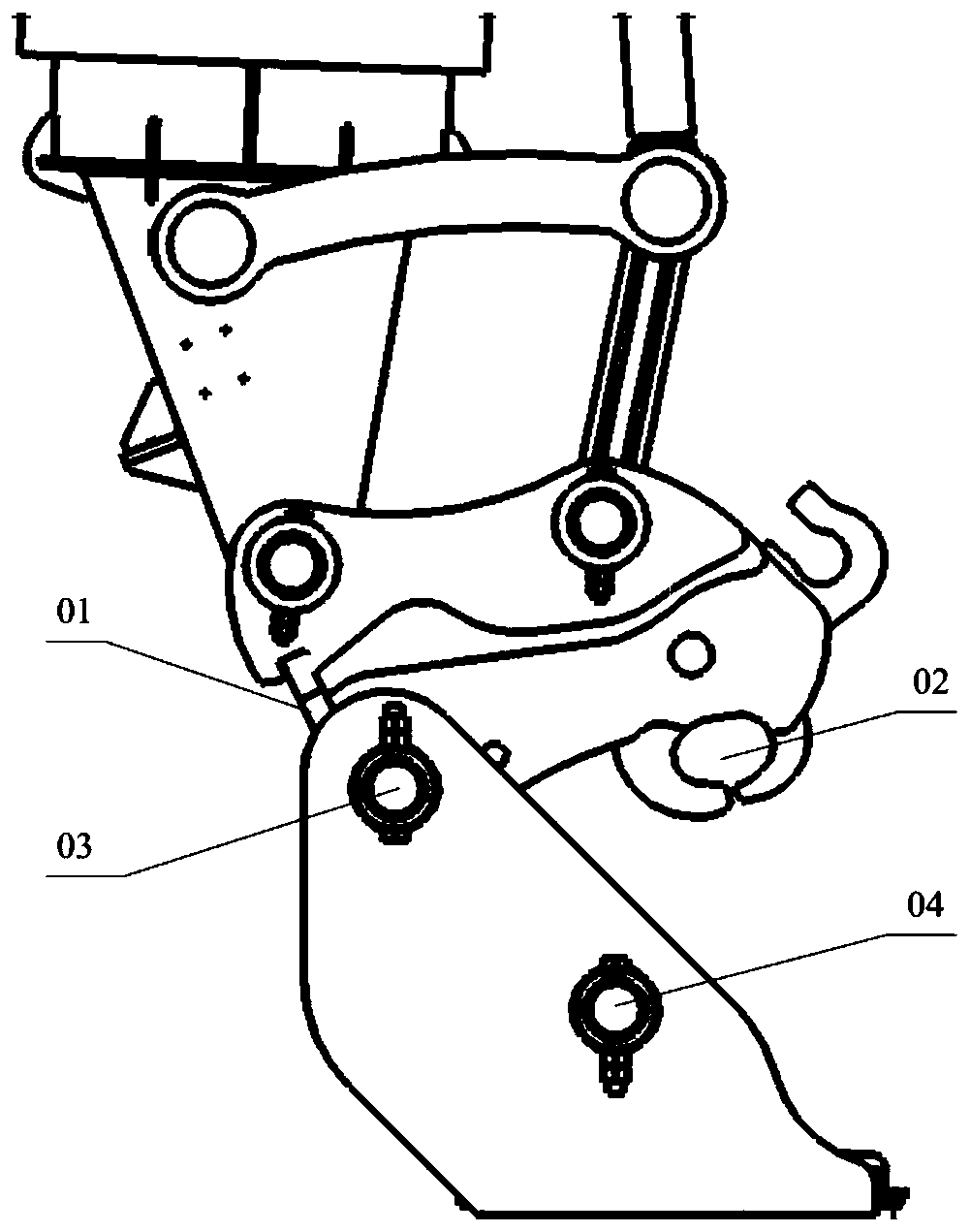

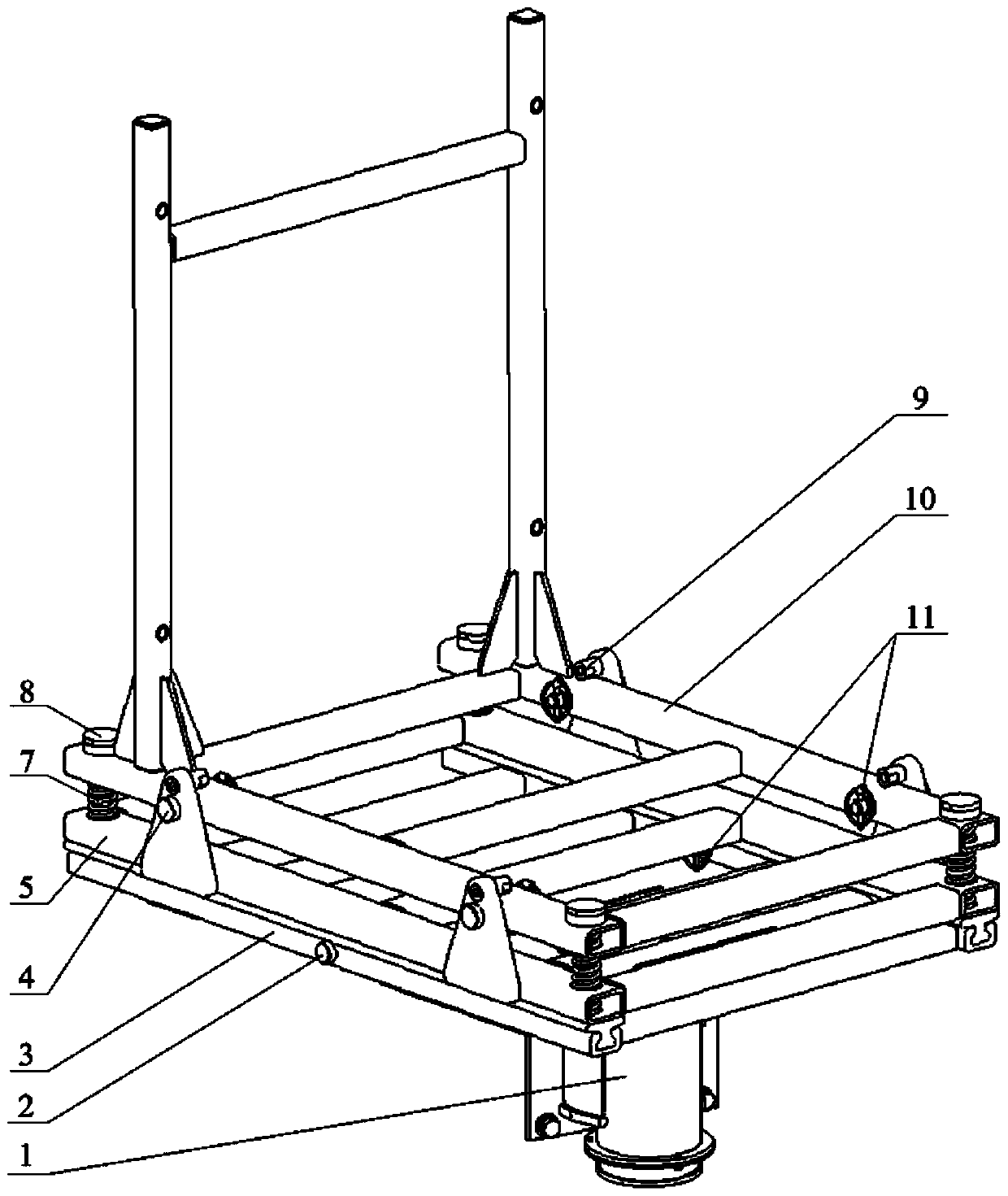

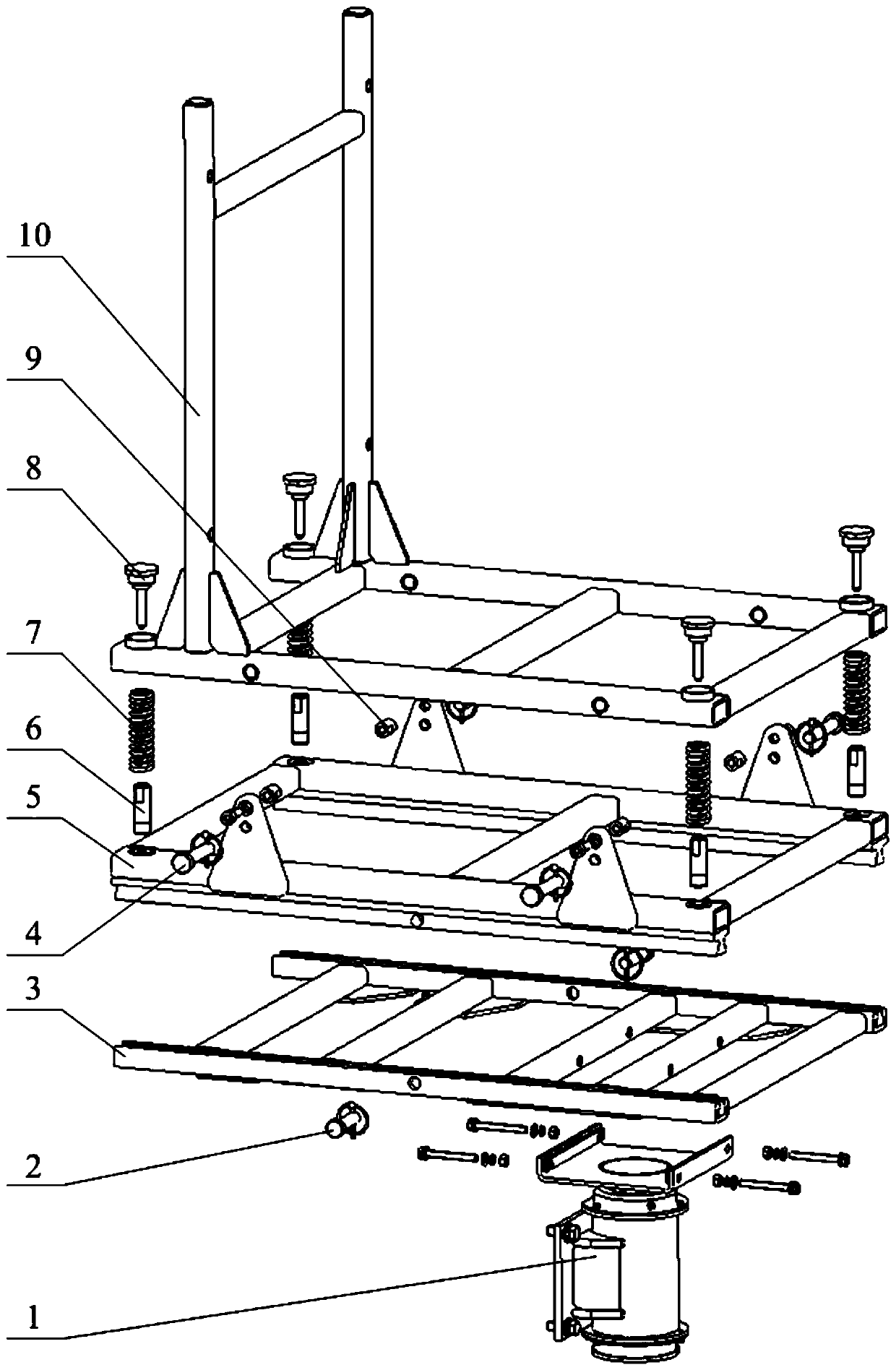

[0042] Such as figure 2 , image 3 and Figure 4 As shown, a quick-change implement bracket for an engineering vehicle includes a rotating bracket 1 , a lower platform 3 , an intermediate platform 5 and an upper platform 10 . Among them, the rotating bracket 1 and the lower platform 3 are fixedly connected by a bolt group; the lower platform 3 and the middle platform 5 are slidably connected by slide rails, and are locked by two sets of first locking pins 2 and O-shaped cards 11 in the transportation state (stationary state). The two are fixed to avoid relative sliding; there are four pre-compressed anti-loosening springs 7 between the middle platform 5 and the upper platform 10, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com