Reinforced telescopic device for corrugated pipe joints

The technology of a bellows section and a telescopic device is applied in the field of bellows, which can solve the problems of non-contraction at the joint, poor pressure resistance of the nozzle, poor connection strength, etc., and achieve the effects of high connection strength, good sealing effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

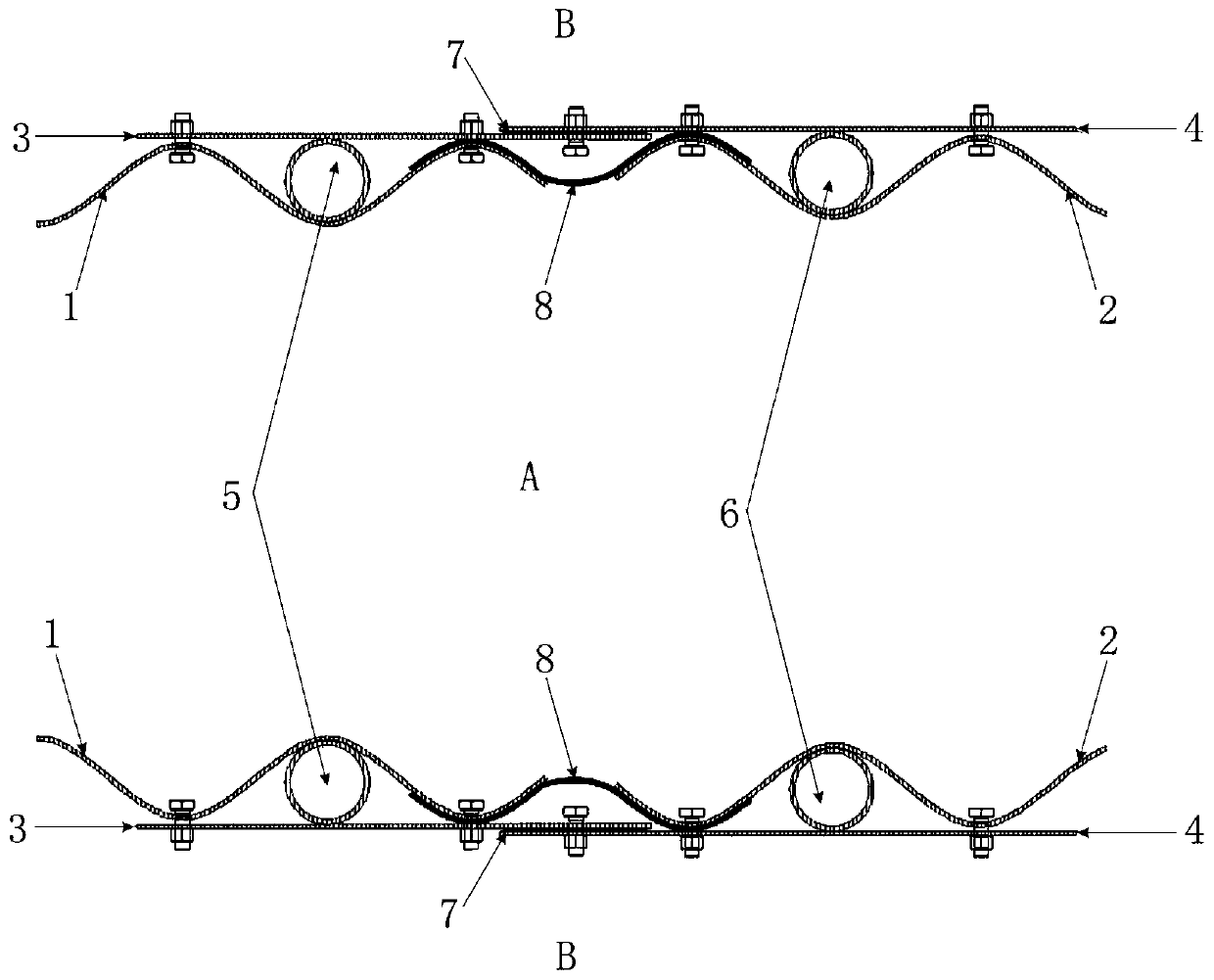

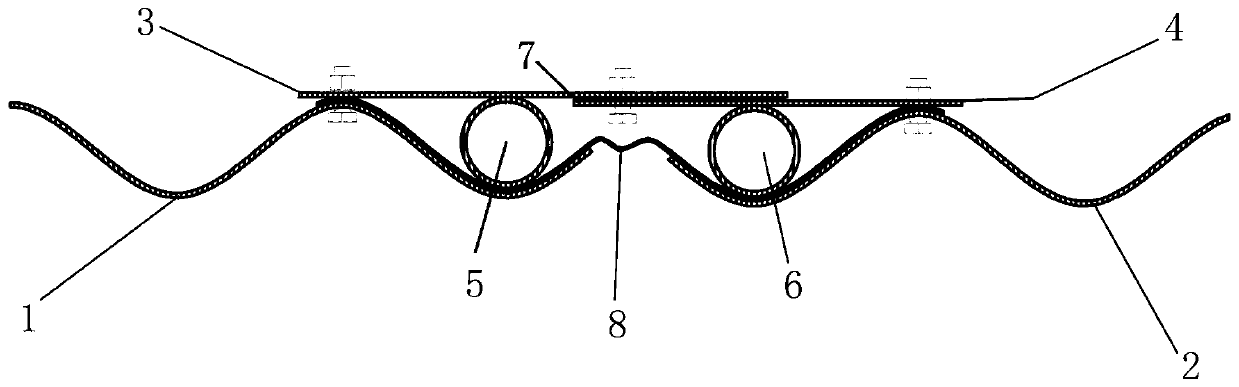

[0034] The following is based on figure 1 , 3 -5 Describe in detail a reinforced bellows joint expansion device according to the embodiment of the present invention.

[0035] Such as figure 1 As shown, the embodiment of the present invention discloses a reinforced bellows joint expansion device, which is used to connect two adjacent bellows—the first bellows 1 and the second bellows 2 (wherein, in the figure, A is inside the pipe, B is the outside of the pipe), in order to prevent the damage of the pipe body caused by the uneven settlement of the foundation at the joint, the specific technical scheme is as follows:

[0036] The reinforced bellows joint telescopic device includes a first telescopic sheet 3 fixed on the outer surface of the first bellows 1 and a second telescopic sheet 4 fixed on the outer surface of the second bellows 2, the first telescopic sheet 3 and the second Two telescopic sheets 4 are curved steel plates.

[0037] Such as Figure 3-5 As shown, the f...

Embodiment 2

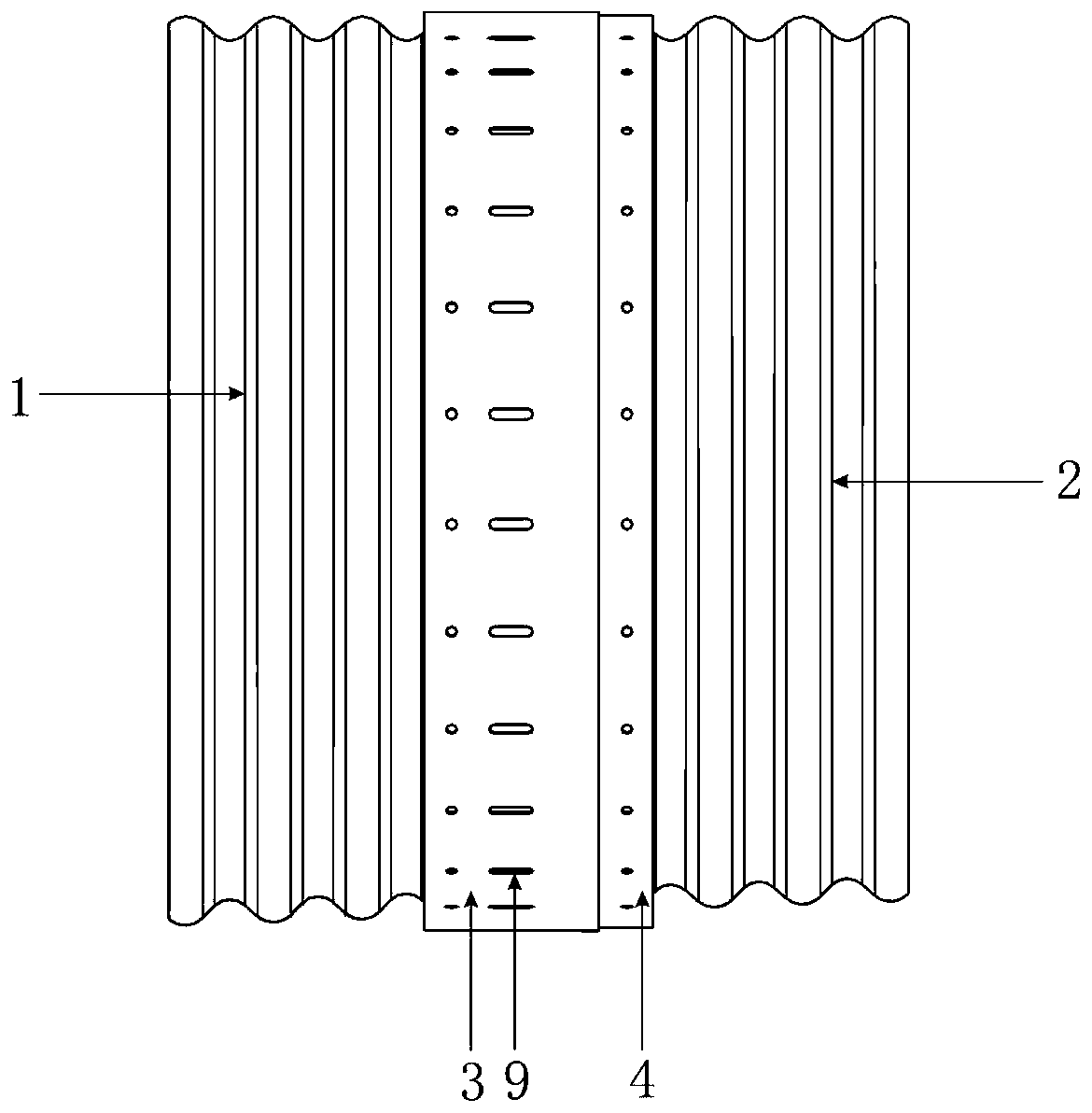

[0044] Such as Figure 2-4 , 6, the structure of the first telescopic sheet 3 and the second telescopic sheet 4 in the reinforced bellows joint telescopic device of this embodiment is basically the same as the structure of the telescopic sheet in Embodiment 1, the only difference is that the first telescopic There is only one row of circular holes on the sheet 3 and the second telescopic sheet 4, and the corrugated pipe is also provided with corresponding circular holes, and the bolts pass through a row of circular holes 10 to firmly connect the telescopic sheet and the corrugated pipe.

[0045] Such as figure 2 As shown, the above embodiment 2 is suitable for the working condition where the edge of the corrugated pipe section is a trough.

[0046] When installing a reinforced bellows joint telescopic device of the present invention, first put the second sealing plate 8 and the two reinforcing rings on the corresponding positions of the two bellows, and then put the first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com