Cement concrete pavement abrasion experiment device

A technology of cement concrete and experimental equipment, which is applied in the direction of measuring equipment, testing wear resistance, instruments, etc., can solve the problems of large inertia of loading parts, large proportion of torsion action, low tire wear speed, etc., and eliminate the speed difference between inner and outer wheels , large loading force, and the effect of saving wear time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the protection scope of the present invention.

[0035] In the present invention, unless stated otherwise, the used orientation words such as "upper and lower" usually refer to the definition based on the drawings of the corresponding drawings, and "inner and outer" refer to the contours of the corresponding parts. inside and out.

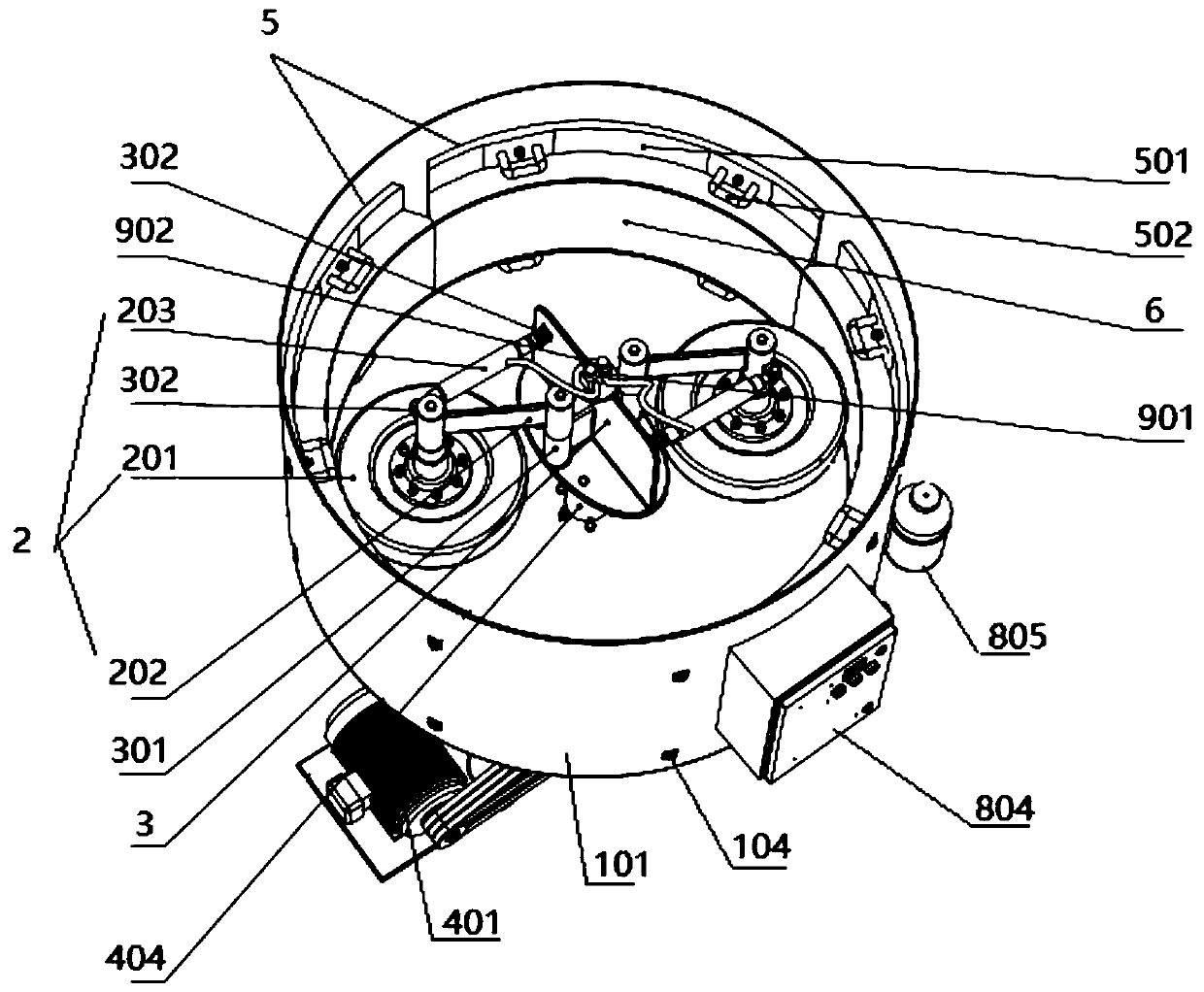

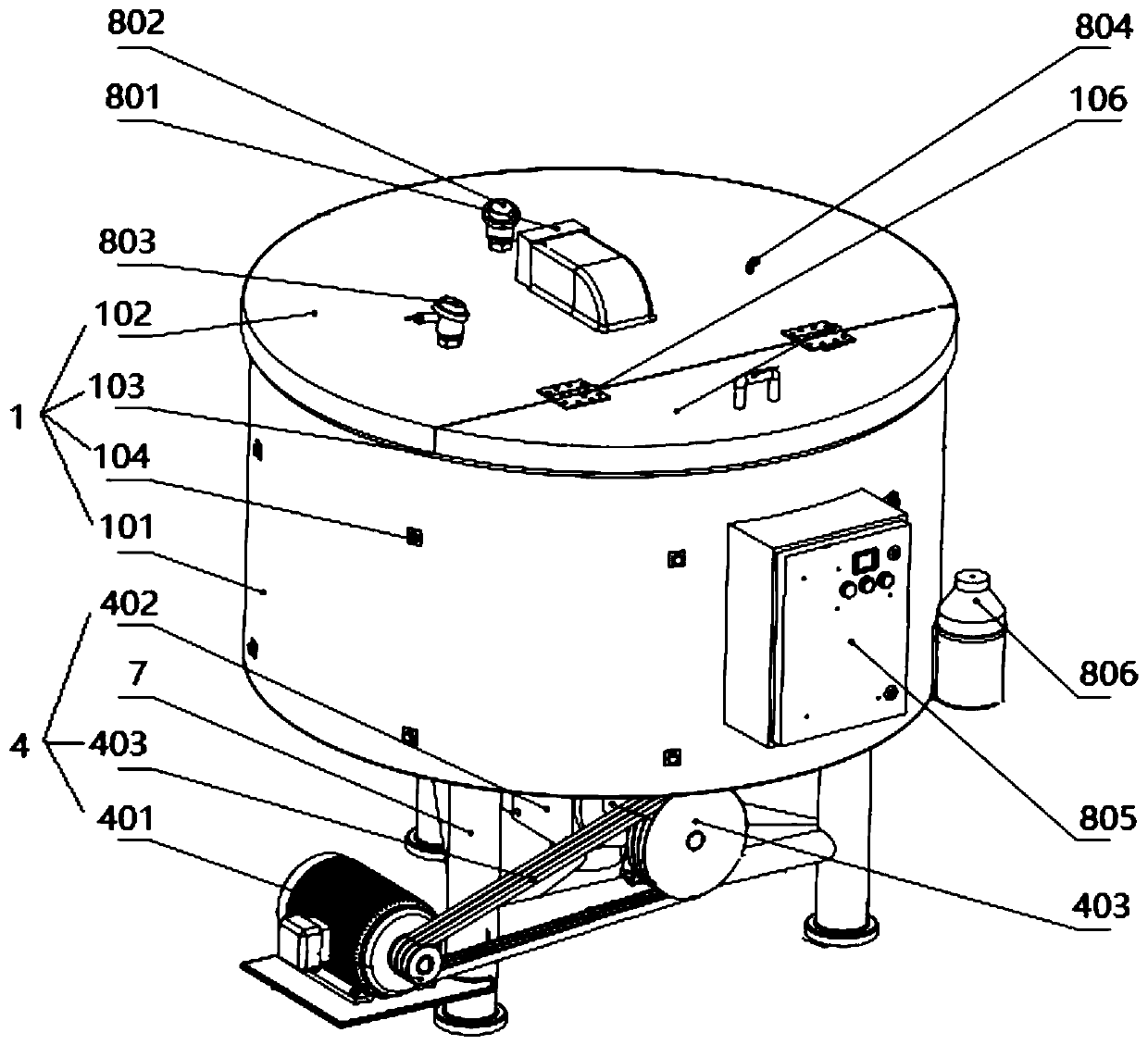

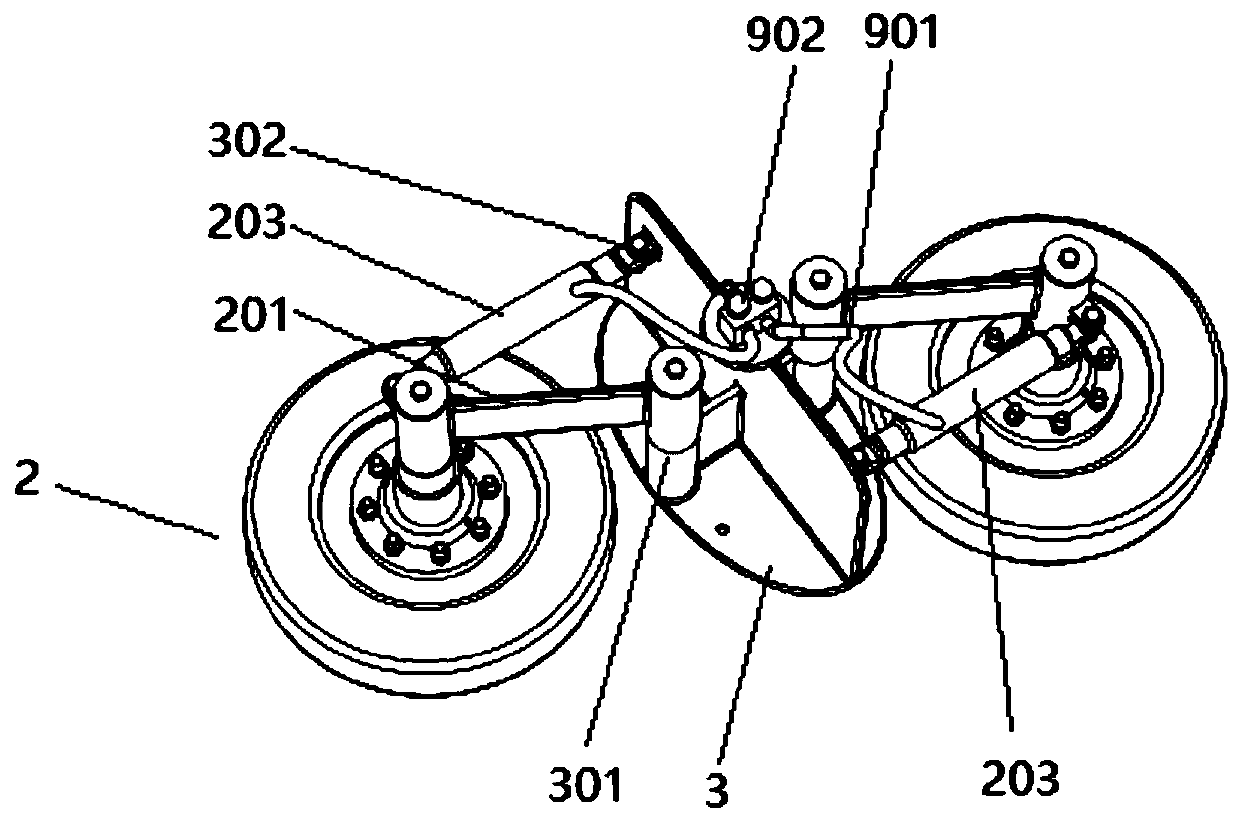

[0036] Such as figure 1 As shown, the present invention discloses a cement concrete pavement abrasion test device, which includes a closed test chamber 1, a loading unit 2 for providing load, and a power unit 4 for driving the loading unit 2 to rotate. The inner side wall of the experimental chamber 1 is provided with a connecting piece 5 for connecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com