Staked nut assembly

A technology of nuts and components, applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problems of large torque of nuts, easy to be affected by vibration, loosening, time-consuming and laborious construction, etc., achieve large fastening pressure, easy Effects of loosening and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

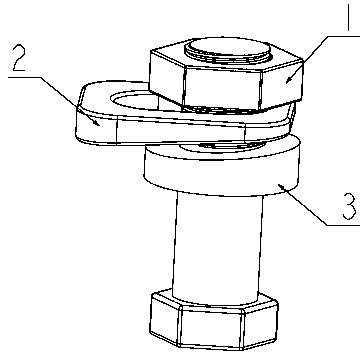

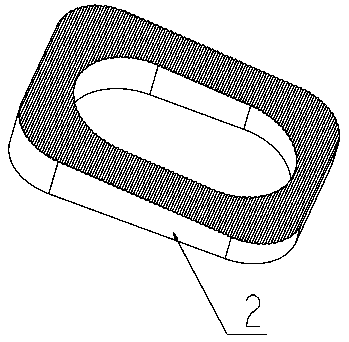

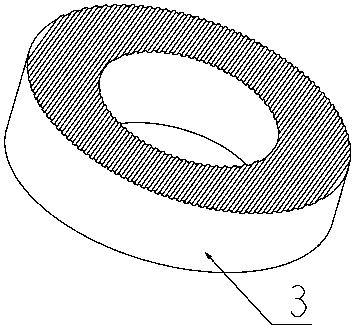

[0029] Example 1, such as figure 1 The knock nut assembly of the present invention shown includes: an upper nut 1, a middle knock washer 2 and a lower bevel washer 3, and the upper nut 1 can be rotated and tightened or loosened on a bolt; the middle knock washer 2 The surface in contact with the lower bevel gasket 3 is a bevel, that is, wedge-shaped, with a strip-shaped hole on it, and the two ends of the hole are semicircular; the contact surface of the lower bevel gasket 3 and the middle tightening gasket 2 is a bevel, The inclination of the bevel is the same as that of the bevel of the middle knocking washer 2; the knocking nut assembly can be tightened or loosened by knocking the middle knocking washer 2. When the nut is tightened, the upper nut 1 is first rotated and tightened slightly, and then the middle tightening washer 2 is struck to tighten the tightening nut assembly; After loosening, the tightening nut assembly can be directly removed or the upper nut 1 can be ro...

Embodiment 2

[0030] Example 2, such as figure 2 and 3 As shown in the tightening nut assembly of the present invention, there are concave and convex grooves on the inclined surface of the middle tightening gasket 2 and the inclined surface of the lower inclined gasket 3, which are used to prevent the tightening nut assembly from loosening.

Embodiment 3

[0031] Example 3, such as Figure 4 As shown in the tightening nut assembly of the present invention, after the middle tightening washer 2 is tightened, the end of the middle knocking washer 2 is knocked, so that the end of the middle tightening washer 2 is bent, which can prevent the tightening nut assembly from loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com