A modification method for zsm-11 molecular sieve catalyst used in ethanol dehydration to ethylene reaction

A technology of ZSM-11 and ethanol dehydration, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

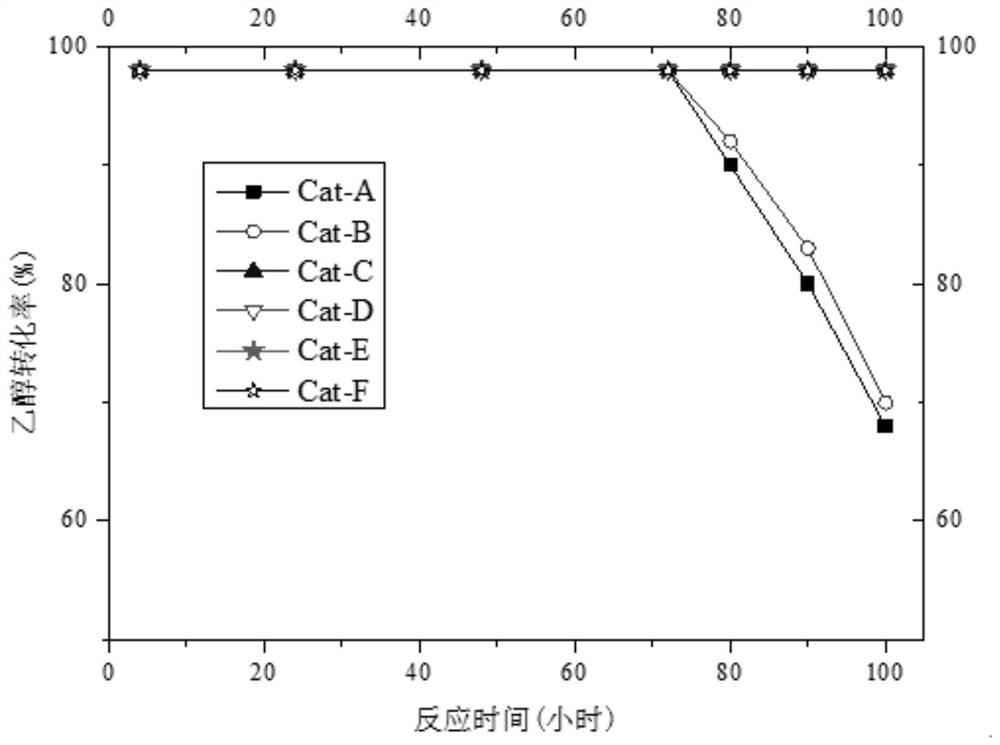

Embodiment 1

[0021] Mix 9.4g ZSM-11 molecular sieve (dry basis 85%) with 6.8g silica sol (dry basis 30%), extrude, dry at 120°C for 3 hours, roast at 540°C for 3 hours, and then use 0.8mol / l nitric acid The ammonium solution was exchanged at 80°C, dried at 120°C, and roasted at 520°C for 2 hours to obtain sample A. 5g sample A is placed in the 100ml autoclave, then adding 25ml concentration is 0.13mol / L (CH 3 ) 3 PO 4 Solution, seal the autoclave and place it in a rotary oven to rotate continuously, the number of revolutions is 10 revolutions / min, the treatment temperature is 170°C, and the time is 3 hours. The catalyst Cat-C was obtained after calcination at ℃ for 3 hours. Gained catalyst Cat-C detects through XRF, the Na in this catalyst 2 O is less than 0.05wt%, P content is 2wt%.

Embodiment 2

[0023] Mix 5.9g ZSM-11 molecular sieve (dry basis 85%) with 16.6g silica sol (dry basis 30%), extrude, dry at 80°C for 10 hours, roast at 600°C for 2 hours, and then use 0.5mol / l nitric acid The ammonium solution was exchanged at 90°C, dried at 120°C, and roasted at 520°C for 2 hours to obtain sample B. 5g sample B is placed in 100ml autoclave, then add 20ml concentration and be 0.08mol / L (CH 3 ) 3 PO 4 Solution, seal the autoclave and place it in a rotary oven to rotate continuously, the number of revolutions is 5 revolutions / min, the treatment temperature is 180°C, and the time is 1 hour. Then the processed sample is transferred to an open beaker, dried at 100°C for 5 hours, and dried at 450°C. The catalyst Cat-D was obtained after calcination at ℃ for 8 hours. Gained catalyst Cat-D is detected by XRF, and the Na in the catalyst 2 O is less than 0.05wt%, P content is 1wt%.

Embodiment 3

[0025] Mix 10.6g ZSM-11 molecular sieve (dry basis 85%) with 3.4g silica sol (dry basis 30%), extrude, dry at 95°C for 8 hours, roast at 500°C for 6 hours, and then use 1.0mol / l nitric acid The ammonium solution was exchanged at 70°C, dried at 120°C, and roasted at 520°C for 2 hours to obtain sample C. 5g sample C is placed in the 100ml autoclave, and then adding 50ml concentration is 0.10mol / L (CH 3 ) 3 PO 4Solution, seal the autoclave and place it in a rotary oven to rotate continuously, the number of revolutions is 8 revolutions / min, the treatment temperature is 160°C, and the time is 4 hours, then transfer the processed sample to an open beaker, dry at 110°C for 8 hours, and dry at 580 Catalyst Cat-E was prepared after calcination at °C for 4 hours. Gained catalyst Cat-E is detected by XRF, and the Na in the catalyst 2 O is less than 0.05wt%, P content is 3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com