Aromatic methanol alkylation method for removing oxygen-containing compound impurities

A compound and alkylation technology, applied in the direction of chemical change purification/separation, condensation between hydrocarbons and non-hydrocarbons, organic chemistry, etc., to achieve the effects of eliminating adverse effects, low equipment investment and operating costs, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the methylation catalyst: 40%~90% of at least one of ZSM-5 zeolite or MCM-22 zeolite molecular sieve and 15~80% of γ-Al 2 o 3 After the binder is fully mixed, add an appropriate amount of water to knead and shape, dry and 550 o After C is calcined, the catalyst body is obtained. 0.01~5.0% of MgO, La 2 o 3 , CaO and SiO 2 At least one of them is loaded on the catalyst body to obtain the methylation catalyst.

[0024] Preparation method of oxygenate removal catalyst: 10%~95% La 2 o 3 , ZnO, ZrO 2 , CaO, MgO, TiO 2 and Cr 2 o 3 At least one of the oxides and 5~90% γ-Al 2 o 3, silicon oxide or clay binder is fully mixed, add appropriate amount of water and knead it into shape, dry and 450 o After C is calcined, the oxygen-containing compound removal catalyst is obtained.

[0025] The reactor is loaded with a toluene methylation catalyst and an oxygenate removal catalyst respectively from top to bottom, and the mass ratio of the upper ...

Embodiment 2

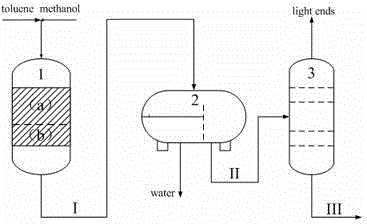

[0030] The reactor is filled with a benzylation catalyst and an oxygenate removal catalyst respectively from top to bottom, and the mass ratio of the upper and lower beds is 1:4. Toluene: methanol (molar ratio) = 3:1, benzene weight space velocity for 2 hours -1 , the reaction temperature is 400°C, and the reaction pressure is 1MPa; after the liquid phase product is separated by the oil-water separator, the oil phase enters the stripper for light component separation, the stripper top temperature is 124°C, and the stripper top pressure is 0.51MPa. As shown in the flow chart, the analysis results of oxygenates such as acetaldehyde, methanol, acetone, butanone and acetic acid in streams I, II and III are shown in Table 2 below.

[0031] Table 2

[0032] Stream I (wtppm) Stream II (wtppm) Stream III (wtppm) Acetaldehyde 15 13 ≤0.5 Methanol 806 65 ≤0.5 acetone ≤0.5 ≤0.5 ≤0.5 butanone ≤0.5 ≤0.5 ≤0.5 Acetic acid ≤0.5 ≤0.5 ≤0....

Embodiment 3

[0035] The reactor is filled with a toluene selective methylation catalyst and an oxygenate removal catalyst respectively from top to bottom, and the mass ratio of the upper and lower beds is 1:1. Toluene: methanol (molar ratio) = 2:1, toluene weight space velocity 4 hours -1 , reaction temperature 450 o C, the reaction pressure is 0.6MPa; after the liquid phase product is separated by the oil-water separator, the oil phase enters the stripping tower for light component separation, the temperature at the top of the stripping tower is 120°C, and the pressure at the top of the stripping tower is 0.50MPa. As shown in the flow chart, the analysis results of oxygenates such as acetaldehyde, methanol, acetone, butanone and acetic acid in streams I, II, III and IV are shown in Table 3 below.

[0036] table 3

[0037] Stream I (wtppm) Stream II (wtppm) Stream III (wtppm) Acetaldehyde 9 7 ≤0.5 Methanol 106 18 ≤0.5 acetone ≤0.5 ≤0.5 ≤0.5 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com