Wet-type double-clutch oil stirring detection method, tool, device and system

A technology of wet double clutch and detection method, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as reducing detection efficiency, and achieve the effect of improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

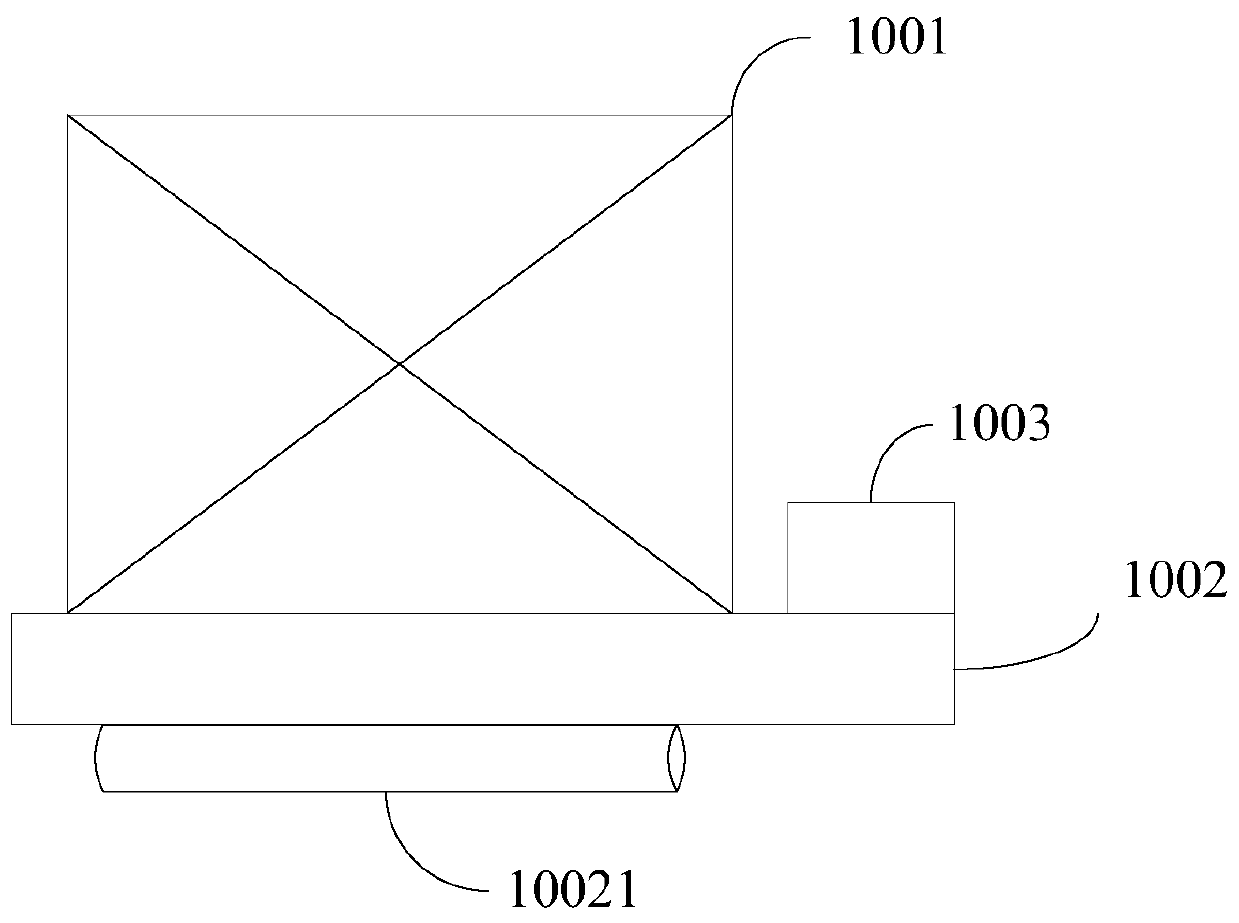

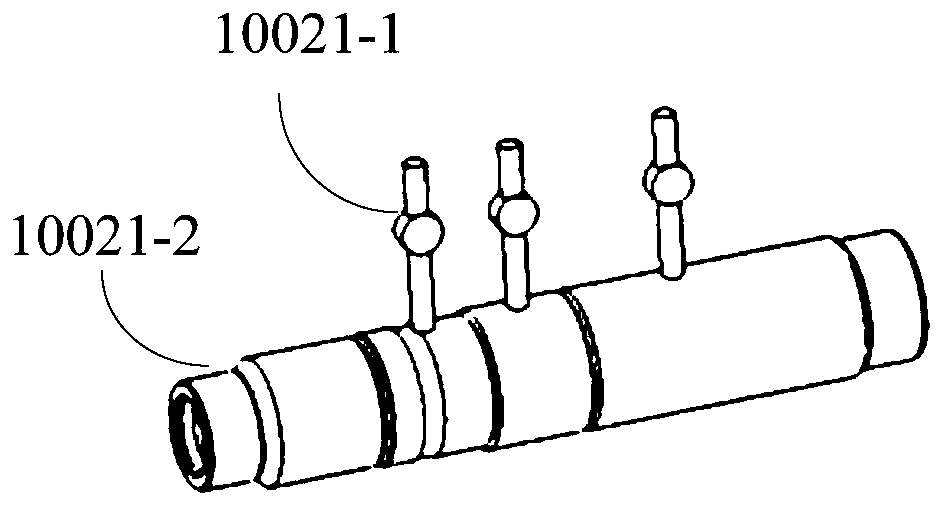

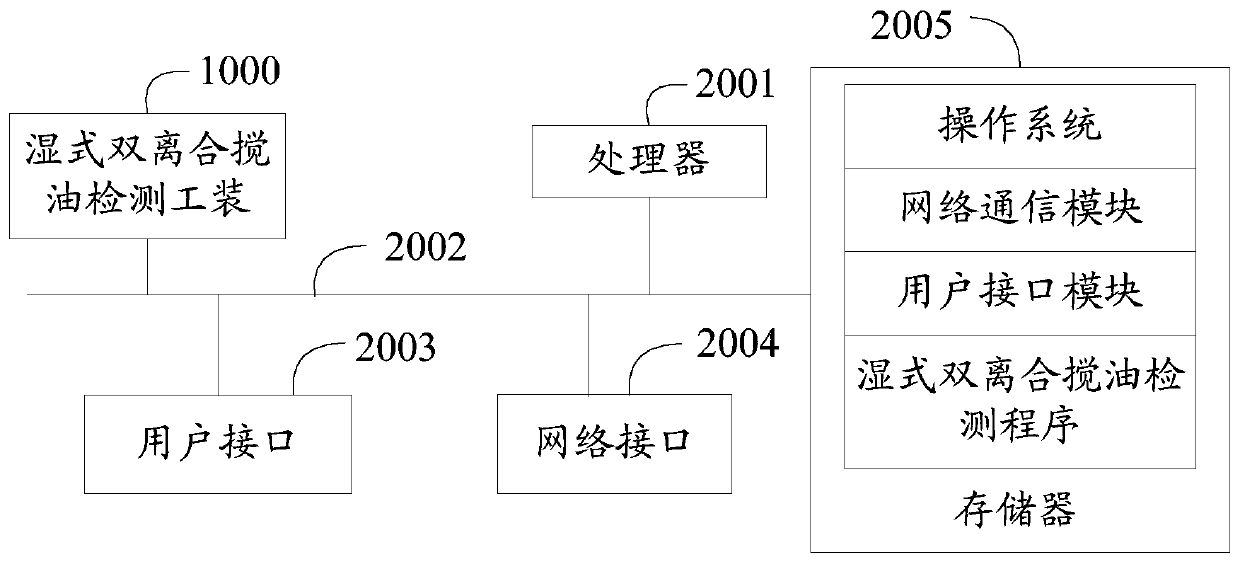

[0038] The main solution of the embodiment of the present invention is: start the input motor to run with different test oil heights, and obtain the output lubricating oil amount after the output motor runs at different test oil heights; determine when the output lubricating oil amount meets the lubrication requirements The test oil height is qualified; if there are multiple test oil heights that pass the test, the lowest test oil height is output as the oil height detection result.

[0039] Because the prior art can only manually detect the proper churning oil quantity of the dual clutch in the testing stage, the testing efficiency is too low.

[0040] The present invention provides a solution. Multiple test oil volume heights are limited by equipment parameters, the current test result is determined according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com