A method and system for automatically adjusting the working posture of a forklift working device

A working device and automatic adjustment technology, applied in the direction of lifting device, etc., can solve the problem of bumping of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

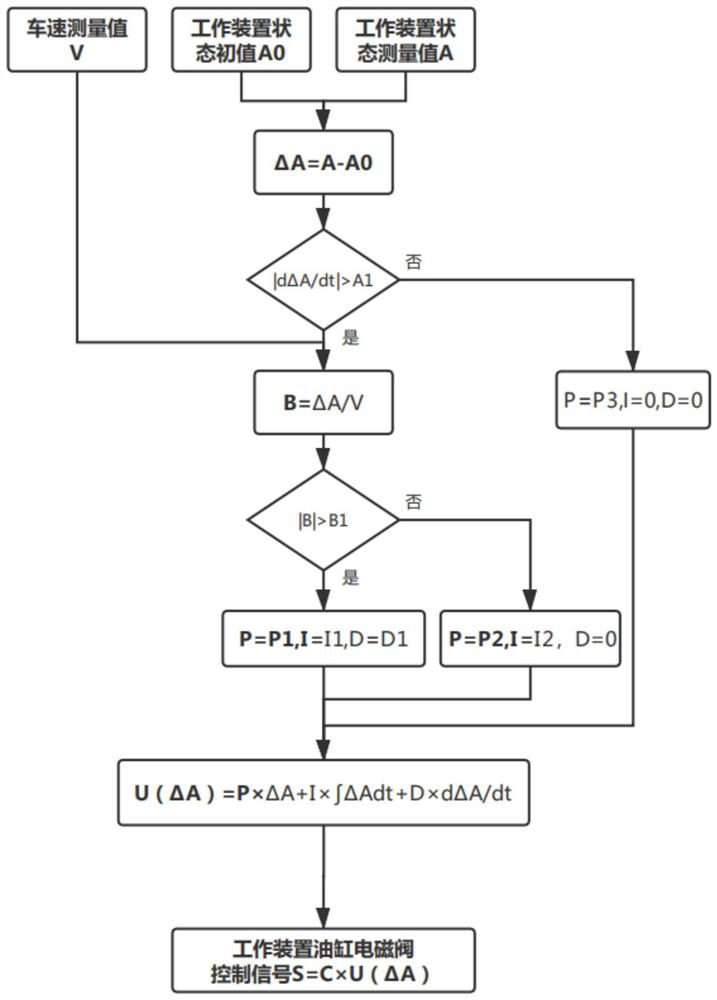

[0053] This embodiment provides a method for automatically adjusting the working attitude of a forklift working device, such as figure 1 As shown, the control method for automatically adjusting the working posture of the forklift working device includes:

[0054] S1, after the forklift starts to drive with cargo, obtain the initial attitude value A0 of the forklift working device; and collect the attitude measurement value A of the forklift working device in real time after obtaining the initial attitude value A0;

[0055] It should be noted that the storage conditions for the initial attitude value A0 of the forklift working device are: the direct or indirect drive cylinder of the forklift working device does not act (the controller has no output), the forklift has a driving or steering action, and the preset time is maintained; Specifically, in this embodiment, the preset time is 3 seconds.

[0056] The attitude of the working device of the forklift can include the angle of...

no. 2 example

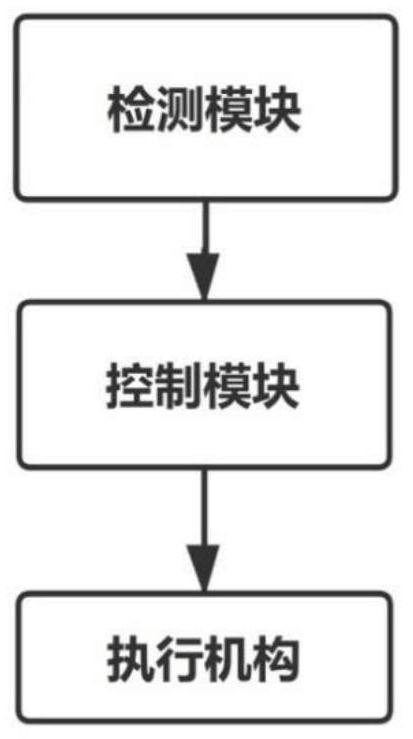

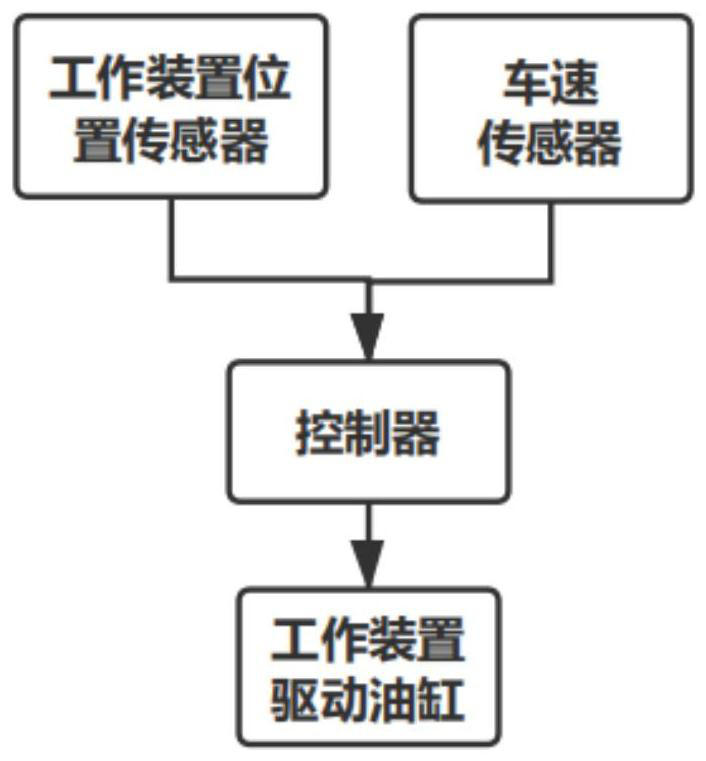

[0081] This embodiment provides a control system for automatically adjusting the working posture of a forklift working device, such as figure 2 As shown, the automatic adjustment control system for the working posture of the forklift working device includes:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com