Motor active speed-reduction buffer system for measurement and control of forklift stroke

A buffer system and forklift technology, applied in the direction of lifting devices, etc., can solve the problems of non-reusable, easy rebound, energy dissipation, etc., and achieve the effects of avoiding large energy loss, improving comfort, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation

[0029] The detailed structural features of the present invention will now be described in detail in conjunction with the accompanying drawings.

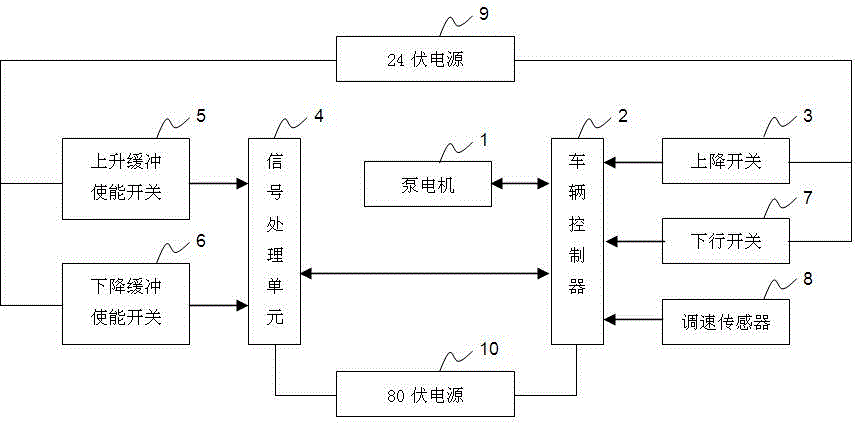

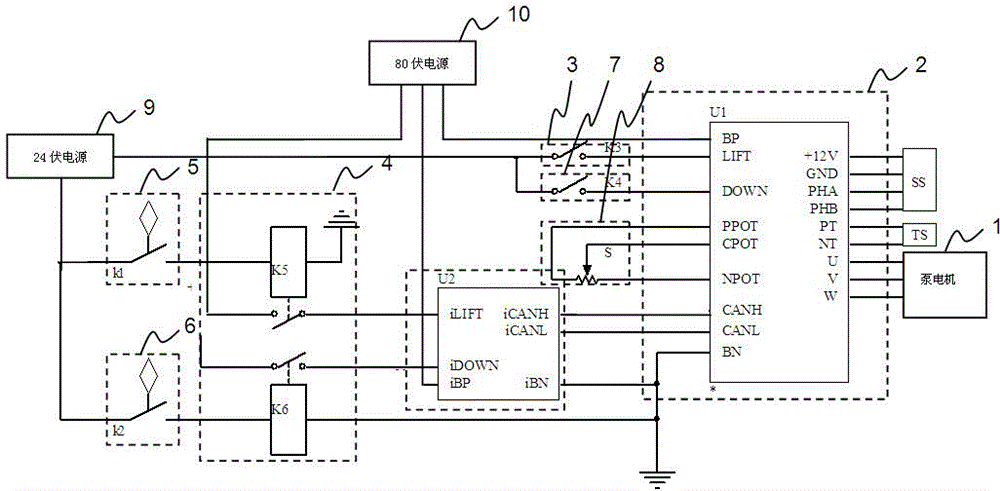

[0030] see figure 1 , the motor active deceleration buffer system for forklift travel measurement and control, including pump motor 1, vehicle controller 2, up switch 3, down switch 7, 24 volt power supply 9 and 80 volt power supply 10; Volt power supply 9 is connected with the signal input end of vehicle controller 2; 24 volt power supply 9 is connected with the signal input end of vehicle controller 2 by drop switch 7; Vehicle controller 2 is connected with pump motor 1 and 80 volt power supply 10 respectively In addition, a signal processing unit 4, a rising buffer enabling switch 5 and a falling buffer enabling switch 6 are also provided; wherein, the 24 volt power supply 9 is connected to the signal input terminal of the signal processing unit 4 through the rising buffer enabling switch 5 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com