Elevator guide shoe wheel device and elevator

A technology for elevator guide rails and guide shoes, applied in the field of elevators, can solve problems such as compression deformation, elevator bumps, abnormal noises, etc., and achieve the effects of improving elastic recovery performance, reducing installation space requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

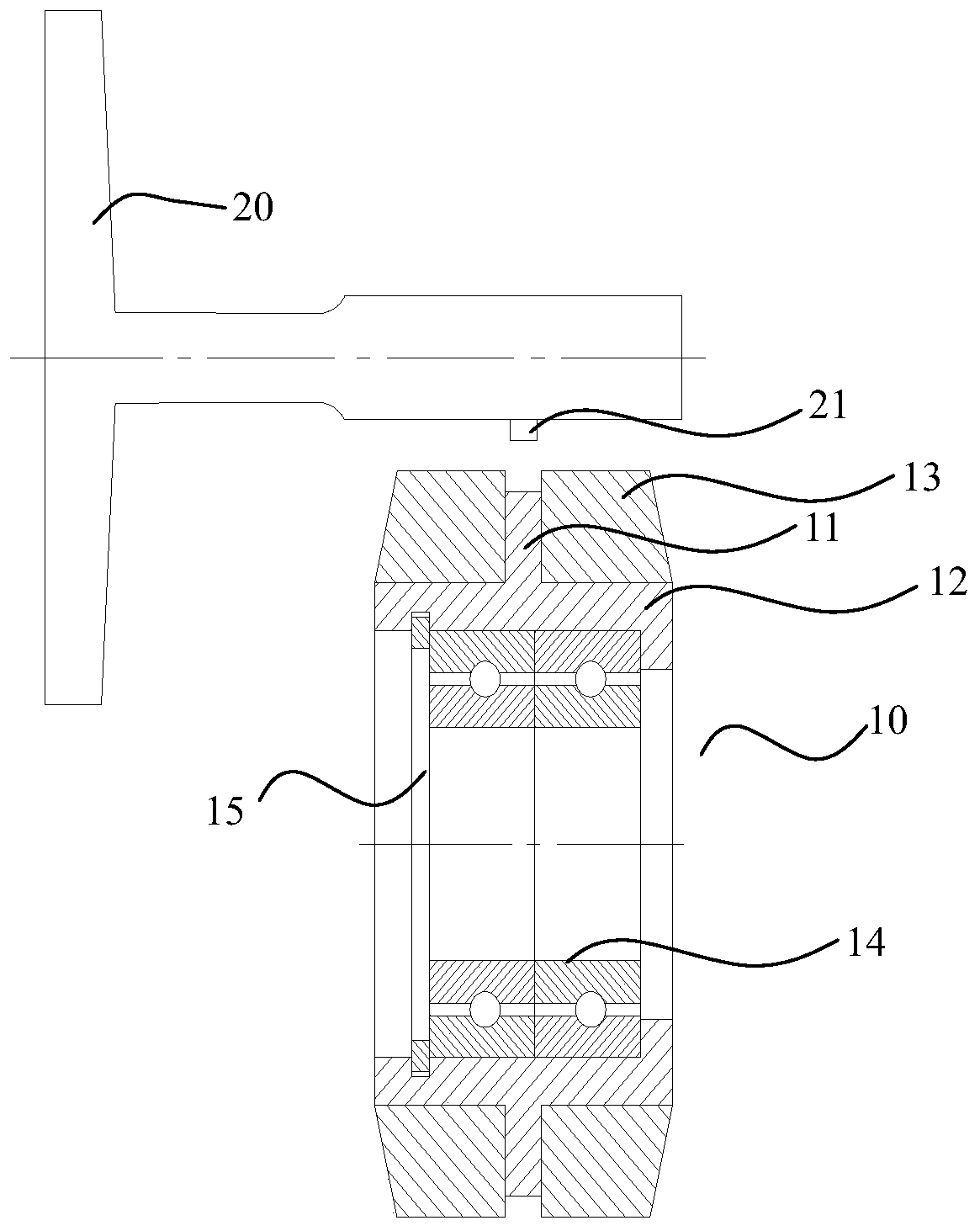

[0032] Such as figure 1 As shown, an elevator guide wheel device in this embodiment includes a guide shoe wheel 10 and an elevator guide rail 20, and a support device 11 is provided on the guide shoe wheel 10; The guide shoe wheel 10 is supported when the wheel 10 is at rest, so that the guide shoe wheel reduces the pressure from the guide rail; the support device 11 is arranged on the wheel hub 12 .

[0033] The elevator guide rail is provided with a bearing device 21; the bearing device 21 is used to abut against the support device 11 of the guide shoe wheel 10 when the guide shoe wheel is at rest, so as to unload the stress of the guide shoe wheel. In this embodiment, the carrying device 21 is a load-relieving block. The shape of the load-relieving block is adapted to the supporting device 11 .

[0034] Owing to having adopted supporting device 11 and carrying device 21, when elevator was in the base (normally the first floor) position, the guide shoe wheel position bondi...

Embodiment 2

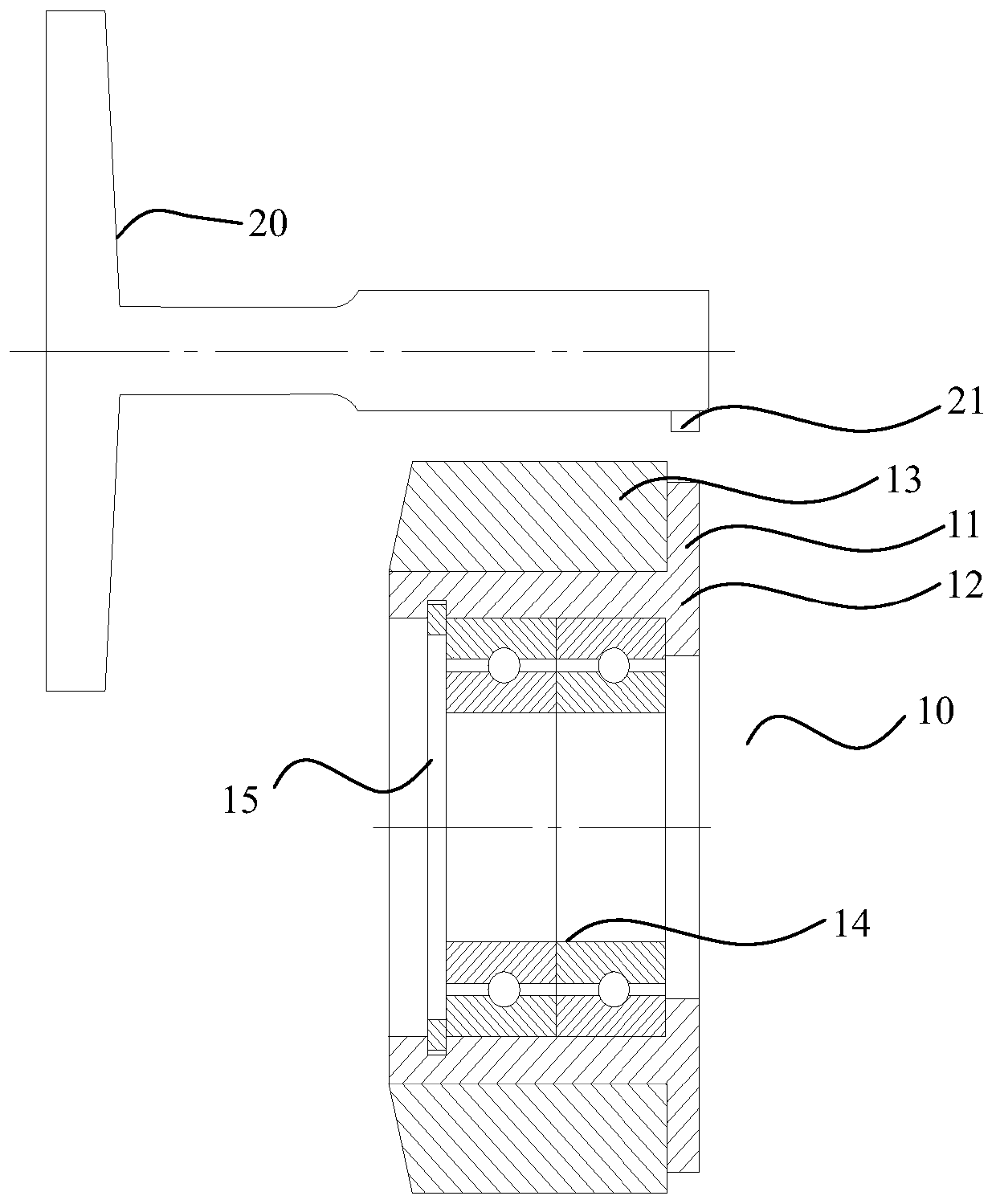

[0049] Such as image 3 As shown, an elevator guide wheel device in this embodiment includes a guide shoe wheel 10 and an elevator guide rail 20, and a support device 11 is provided on the guide shoe wheel 10; The guide shoe wheel 10 is supported when the wheel 10 is at rest, so that the guide shoe wheel reduces the pressure from the guide rail; the support device 11 is arranged on the wheel hub 12 .

[0050] The elevator guide rail is provided with a bearing device 21; the bearing device 21 is used to abut against the support device 11 of the guide shoe wheel 10 when the guide shoe wheel is at rest, so as to unload the stress of the guide shoe wheel. In this embodiment, the carrying device 21 is a load-relieving block. The shape of the load-relieving block is adapted to the supporting device 11 .

[0051] In this embodiment, the supporting device 11 is arranged on one axial side of the annular outer end surface of the hub 12 . This makes product design and installation eas...

Embodiment 3

[0054] On the basis of Embodiment 1 or Embodiment 2, this embodiment discloses an elevator, which adopts the guide shoe wheel device of Embodiment 1 or Embodiment 2, and the guide shoe wheel device is arranged in the backpack type elevator car The upper and lower parts of the shelf. There can be 3 or 6 guide shoe wheels in the present embodiment.

[0055] At the position of the base layer of the elevator (usually the first floor), the unloading block is bonded to the guide rail at the position of the guide shoe wheel. When the elevator runs to the base layer, the unloading block lifts up the rigid guide shoe hub to unload the force of the polyurethane layer. When the elevator runs again, after running out of the position of the unloading block, the polyurethane layer is under pressure. That is to say, when the elevator is parked for a long time, since the polyurethane layer is unloaded and stressed, there will be no crushing. When the elevator runs again, the polyurethane ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com