Ribbon binding device

A technology of binding device and binding seat, which is applied in the direction of cable installation device, cable installation, electrical components, etc., can solve problems such as troubles, and achieve the effect of convenient use, good binding effect and convenient binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

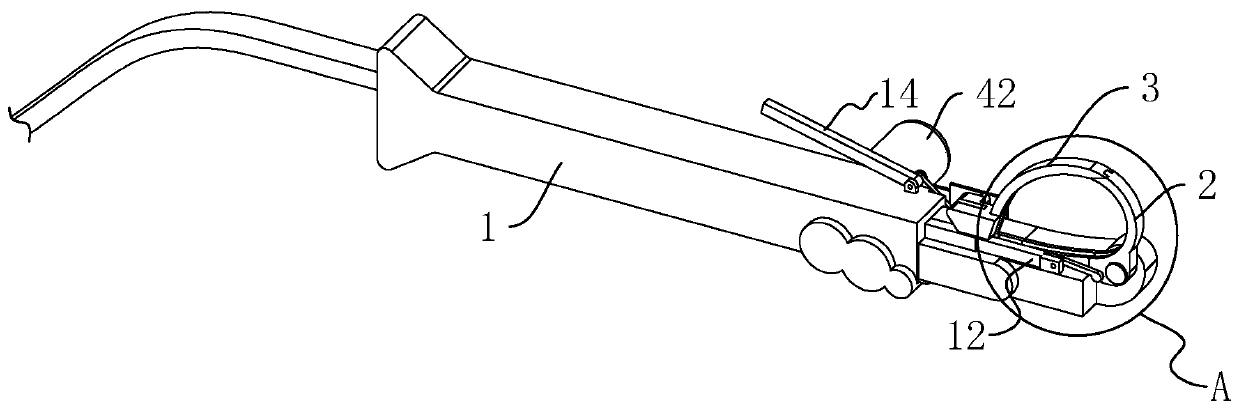

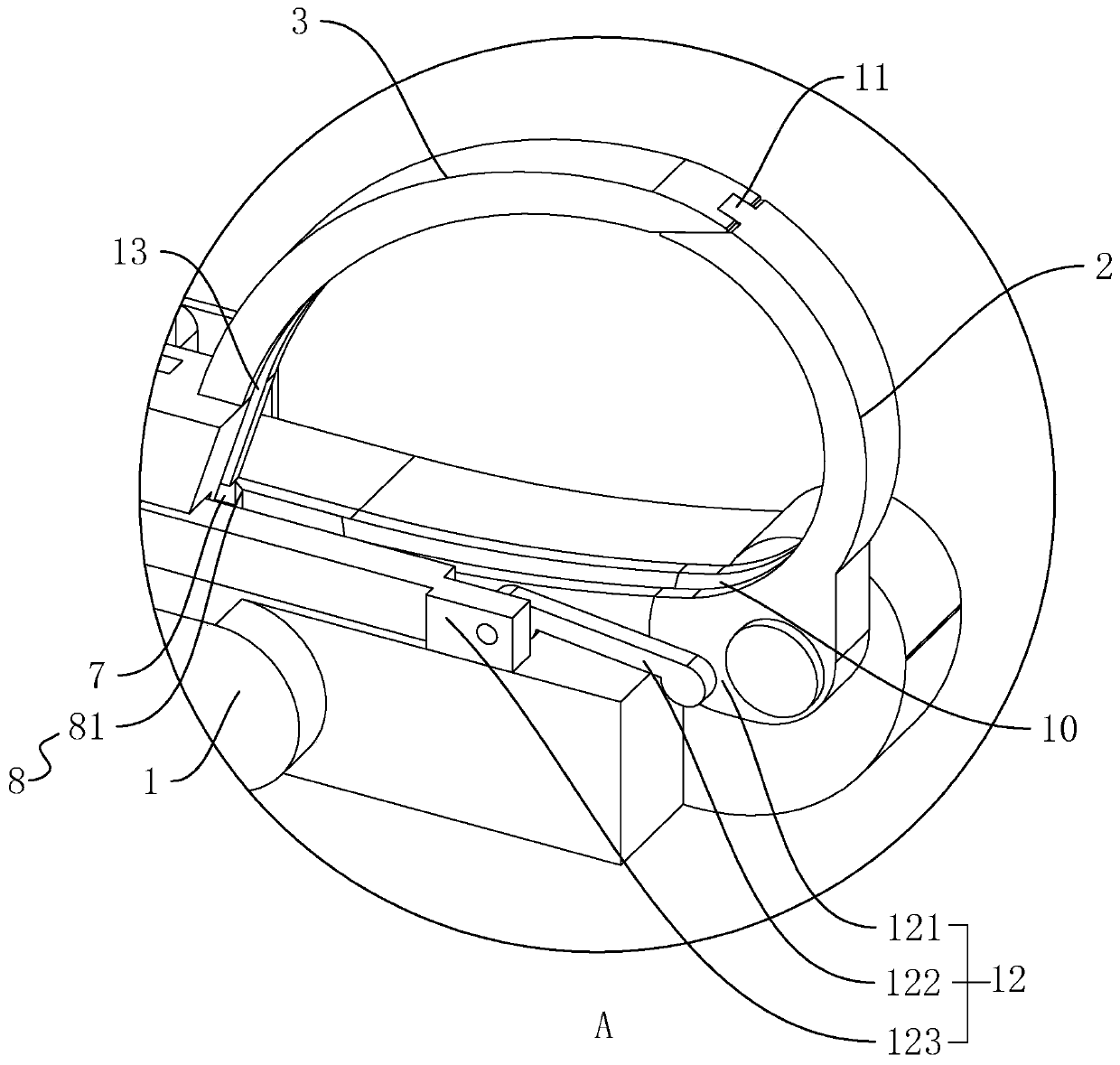

[0048] A cable tie binding device, such as figure 2 , Figure 4 As shown, it includes a binding seat 1 , a binding arm 2 , a guiding arm 3 , a tightening assembly 4 and a cutting assembly 5 .

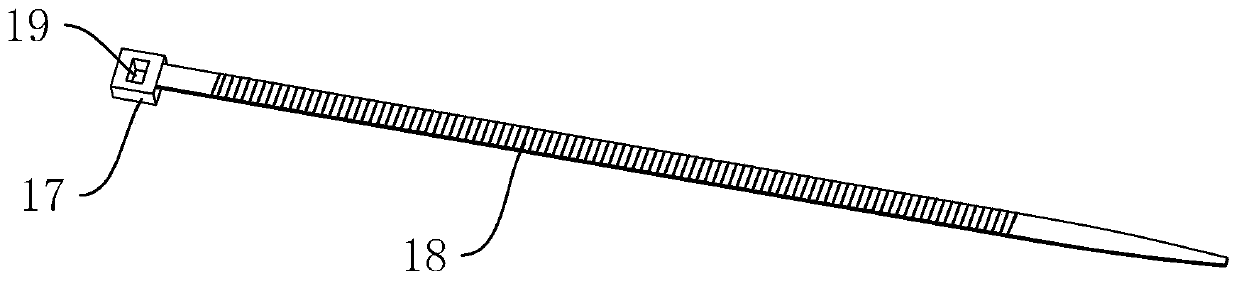

[0049] like image 3 , Figure 4 As shown, the binding seat 1 is provided with a feed channel 6 along the length direction. The feed channel 6 has a square cross-section and is set corresponding to the strap head 17 of the strap. The feed channel 6 is used to limit the rotation of the strap. One end of the feeding passage 6 is connected with a feeding groove 7 , and the feeding groove 7 is set on the binding seat 1 . The feed trough 7 is provided with a limiter 8 near the feed channel 6, the limiter 8 is two limit blocks 81 fixedly connected to the side wall of the feed trough 7, and a tooth is provided between the two limit blocks 81. There is a gap through which the belt 18 passes, and the side wall of each limiting block 81 close to the feed channel 6 is set at an obtuse angle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com