Steel bar cutting machine

A steel bar cutting machine and steel bar technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of steel bar slipping or skewing, the cutting surface of different steel bars is not neat enough, and the steel bar cutting machine lacks steel bar fixing devices, etc., so as to facilitate flow diversion and adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

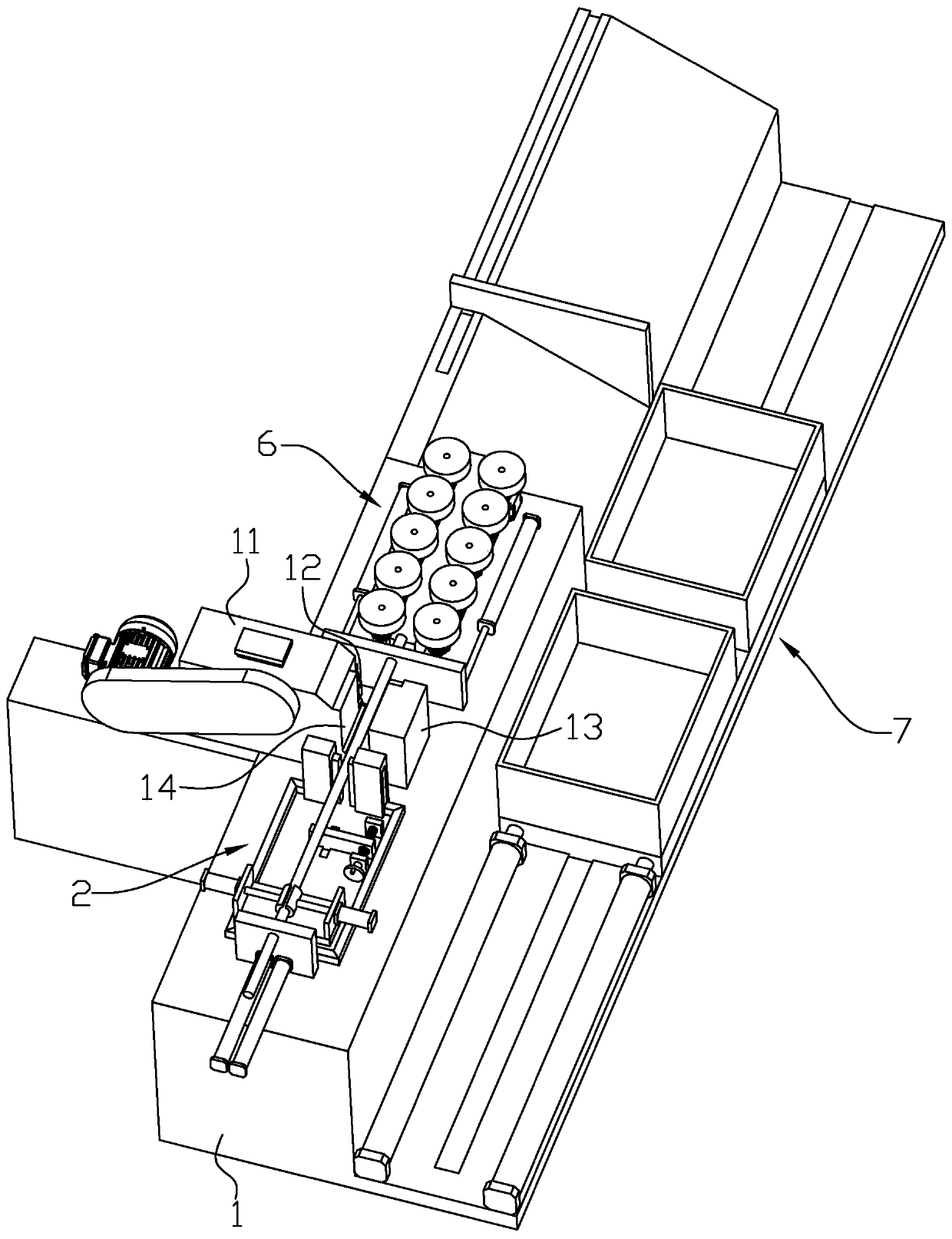

[0033] Such as figure 1 As shown, it is a steel bar cutting machine disclosed by the present invention, including a base 1, a mounting base 11 fixed to the base 1, a cutter 12 mounted on the mounting base 11, a fixing base 13 fixed to the base 1 and a The cutting groove 14 between the mounting seat 11 and the fixing seat 13, and the two sides of the base 1 are respectively equipped with a feeding structure 2 and a discharging structure.

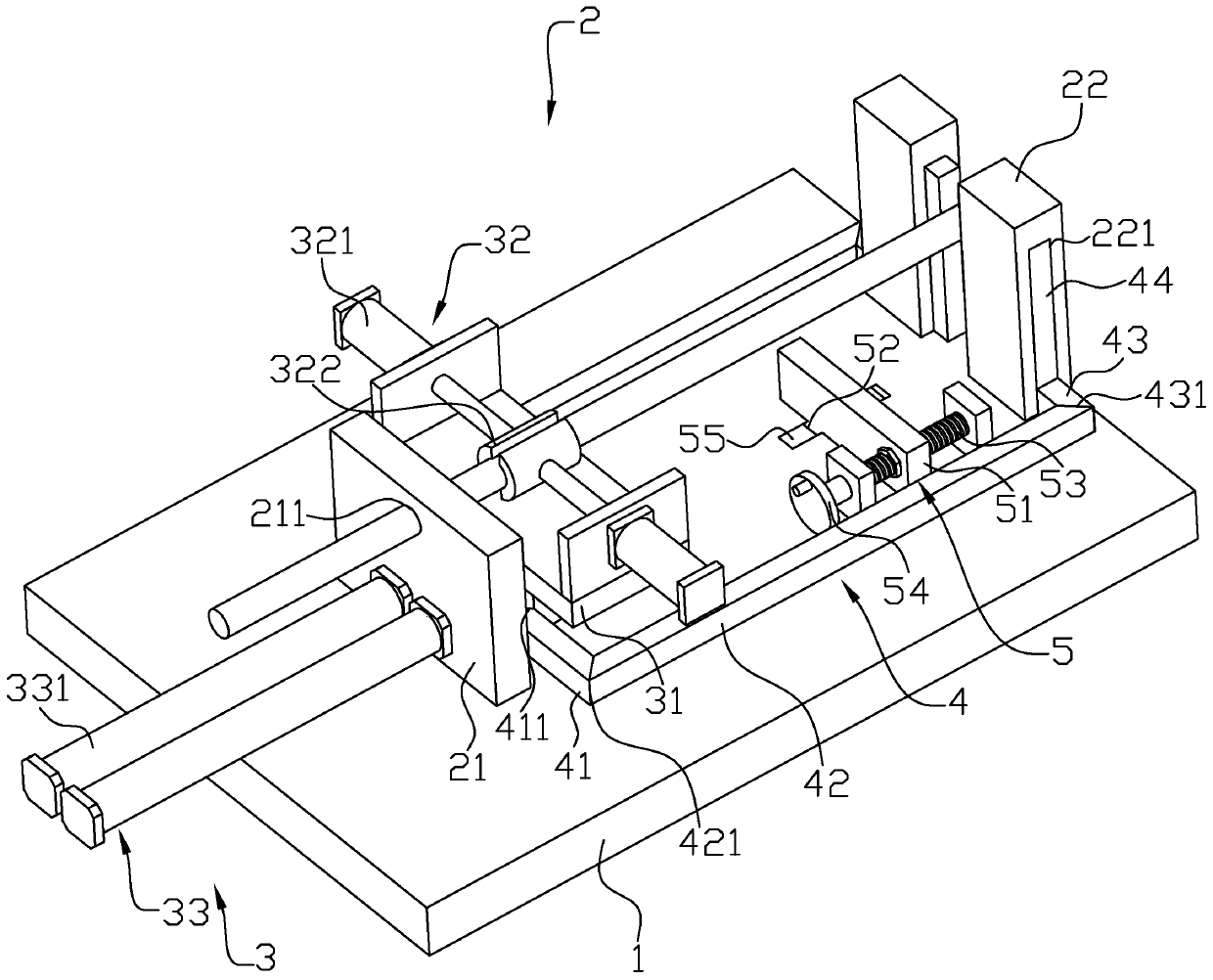

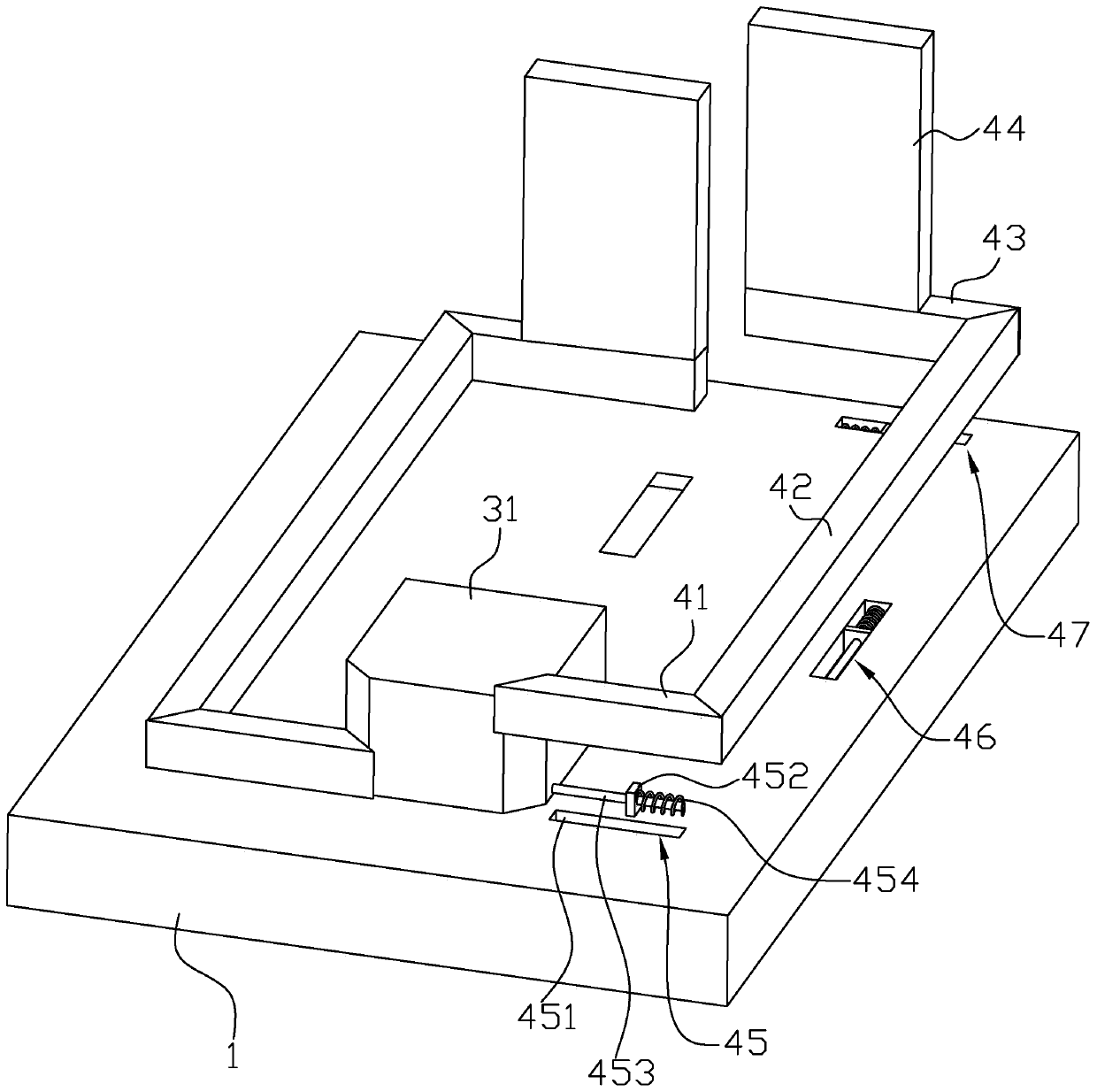

[0034] Such as figure 1 with figure 2 As shown, the feed structure 2 includes a first support plate 21, a transport device 3 and a second support plate 22 arranged in sequence along the transport direction of the steel bar; The transportation direction of steel bars is slidingly connected to the movable plate 31 of the base 1, the clamping mechanism 32 installed on the top of the movable plate 31 for fixing the steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com