A combination mold for processing duct type oil fume backflow and non-return device and method of using the mold

A non-return device and combined mold technology, applied in the field of mechanical processing, can solve the problems of time-consuming and material-consuming, difficult to meet the use requirements, complex modeling of the new non-return device, etc., to reduce manufacturing costs, save processing materials, and use scientific and reasonable methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

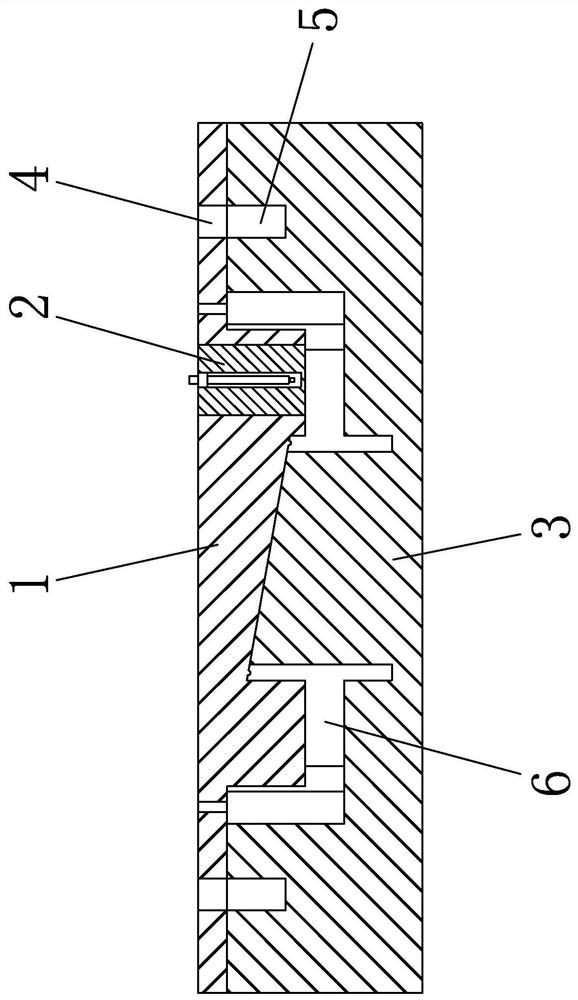

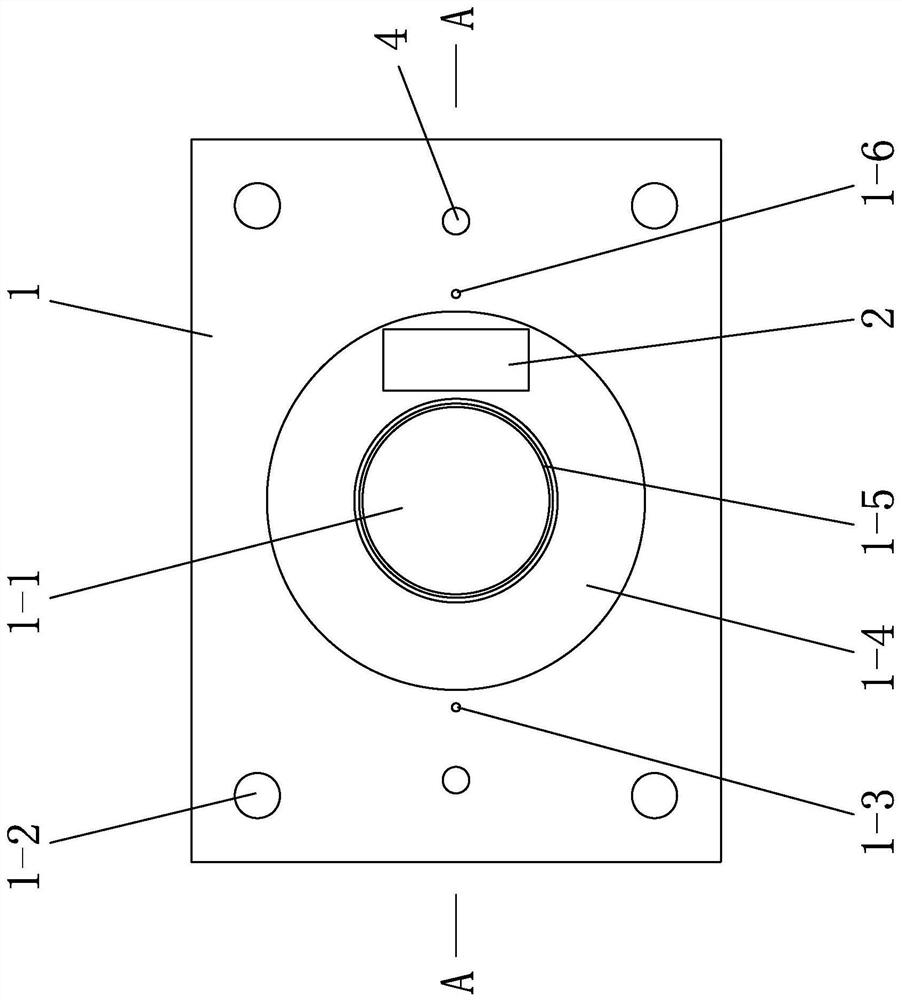

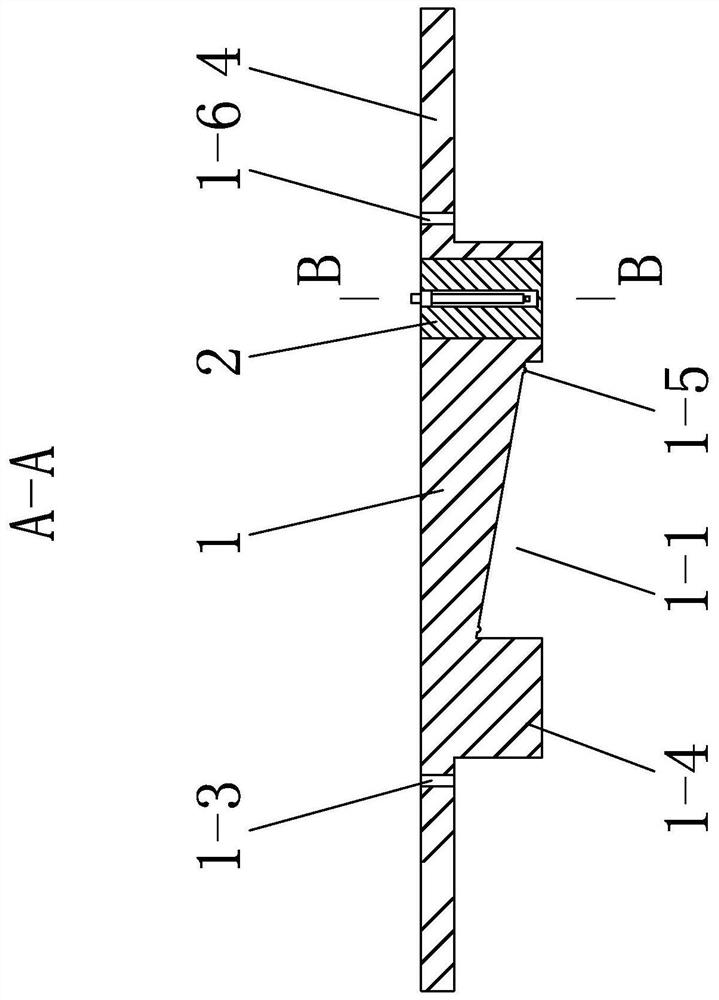

[0032] like figure 1 As shown, a composite mold for processing duct type anti-oil fume backflow and non-return device is composed of upper mold 1, ear mold core 2 and lower mold 3.

[0033] like Figure 1-3 As shown, a combined mold for processing ducted oil fume backflow and non-return devices, the upper mold 1 is composed of an upper mold cavity 1-1, a bolt through hole 1-2, a pouring port 1-3, an upper mold core 1-4, The convex ring 1-5 and the exhaust port 1-6 are composed; the upper mold 1 is a rectangular block structure, the bolt through holes 1-2 are set at the four corners of the upper mold 1, and the upper mold core 1-4 protrusions are set on the upper In the middle of the mold 1, the upper mold cavity 1-1 is recessed at the center of the upper mold core 1-4, the bottom surface of the upper mold cavity 1-1 is an inclined plane, and the convex ring 1-5 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com