A real-time detection and intelligent control system of grinding surface roughness

An intelligent control system and surface roughness technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., can solve the difficult online roughness detection and high requirements of grinding conditions , complex device structure and operation, etc., to achieve the effect of easy follow-up viewing and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings.

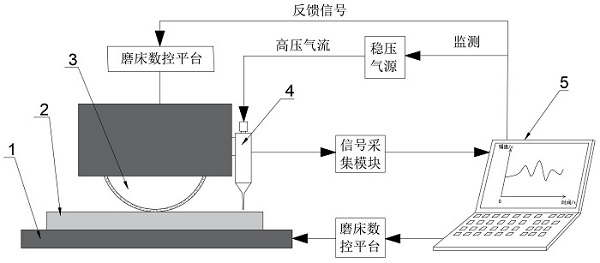

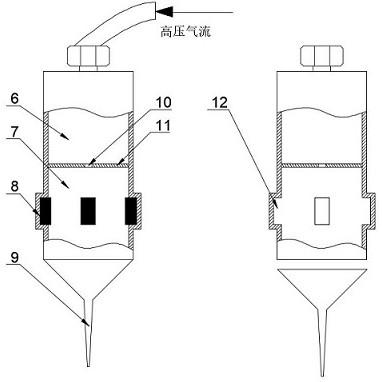

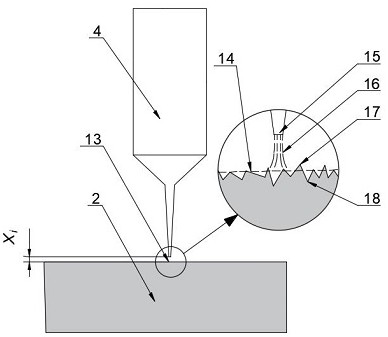

[0027] Such as figure 1 with figure 2 As shown, a grinding surface roughness online detection and intelligent control system is characterized in that: the system includes a roughness detection module, a signal acquisition module and a grinding parameter intelligent control module. The roughness detection module includes an external regulated air source and an air injection device (4), the regulated air source provides a stable high-pressure air flow for the system, and the air injection device (4) consists of a plenum chamber (6), a pressure chamber (7) and a nozzle (9), the plenum (6) and the plenum (7) are separated by a partition (11), and the center of the partition (11) is processed with an air hole (10) to communicate with the plenum (6) and There are multiple groups of air pressure sensors (8) evenly distributed in the pressure changing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com