Label high-speed printing equipment

A high-speed printing and label printing technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of easy temperature fluctuation, low work efficiency, and inability to dry, so as to speed up the drying speed, improve work efficiency, save money energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

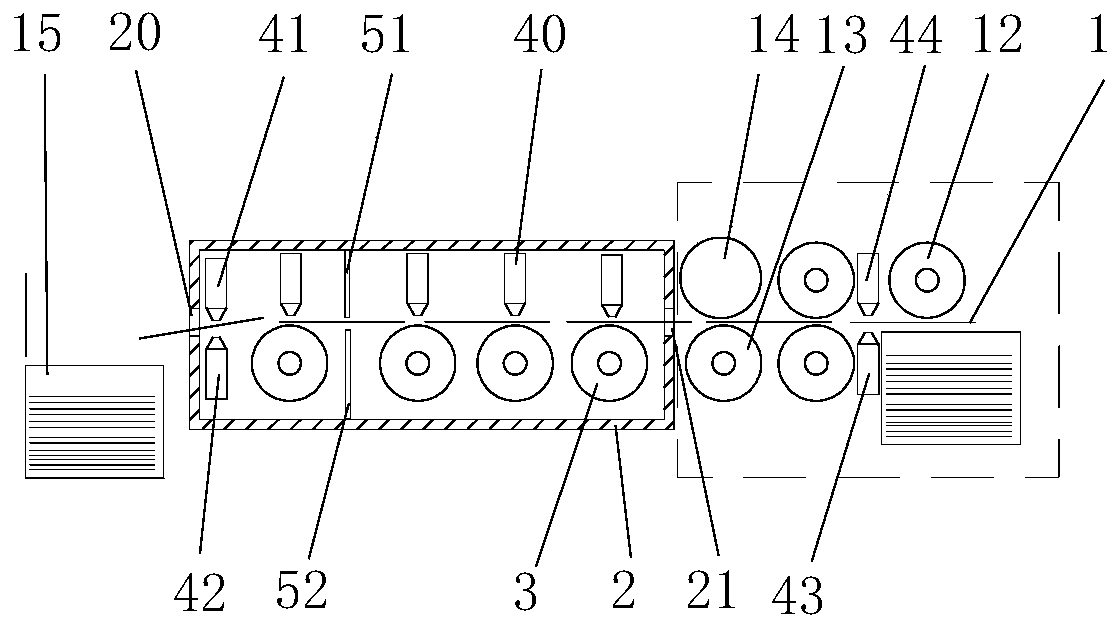

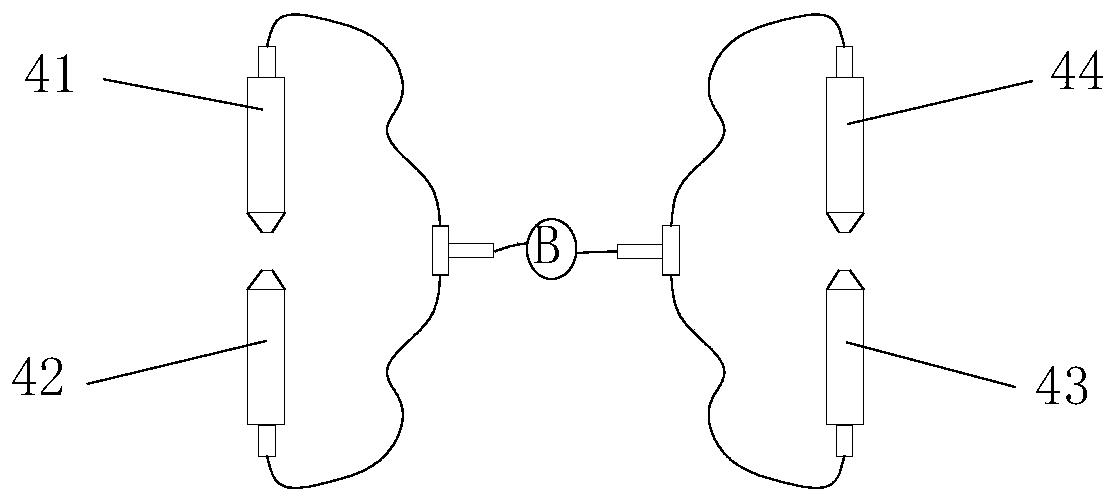

[0020] Now in conjunction with accompanying drawing, the present invention will be further described:

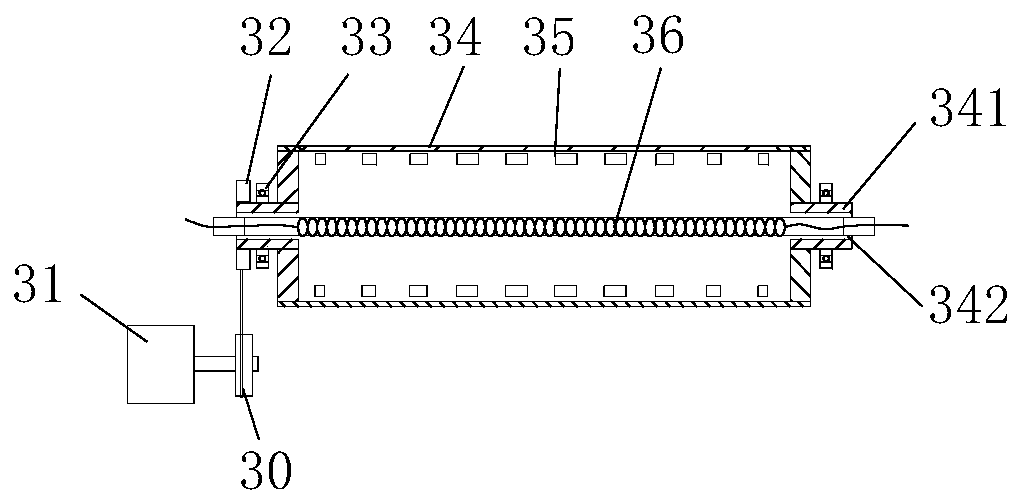

[0021] As shown in the figure, a high-speed label printing equipment includes a label printing equipment body, which is provided with a feeding assembly 12, a printing assembly and a receiving assembly 15, and also includes: a plurality of roller assemblies 3, arranged in a line, fixed on Between the printing assembly and the receiving assembly, the roller assembly 3 includes:

[0022] Roller 34, the wheel core 341 of its two ends is respectively fixed with frame through bearing 33, and roller 34 is hollow structure, and wheel core 341 is provided with core hole 342;

[0023] Infrared heating tube 36, its two ends respectively pass through the core hole 342 of wheel core 341 and fix to the frame, infrared heating tube 36 does not contact with wheel core 341, and the electrodes of infrared heating tube 36 are connected to power supply;

[0024] The light baffle 35 is compose...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap