Laminated glass adhesive film winding system and using method thereof

A technology of laminated glass and adhesive film, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of lower production efficiency, insufficient locking, and the failure of the adhesive film reel to follow the rotation of the rotating roller, etc. , to achieve the effect of improving production efficiency and ensuring the effect of locking and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

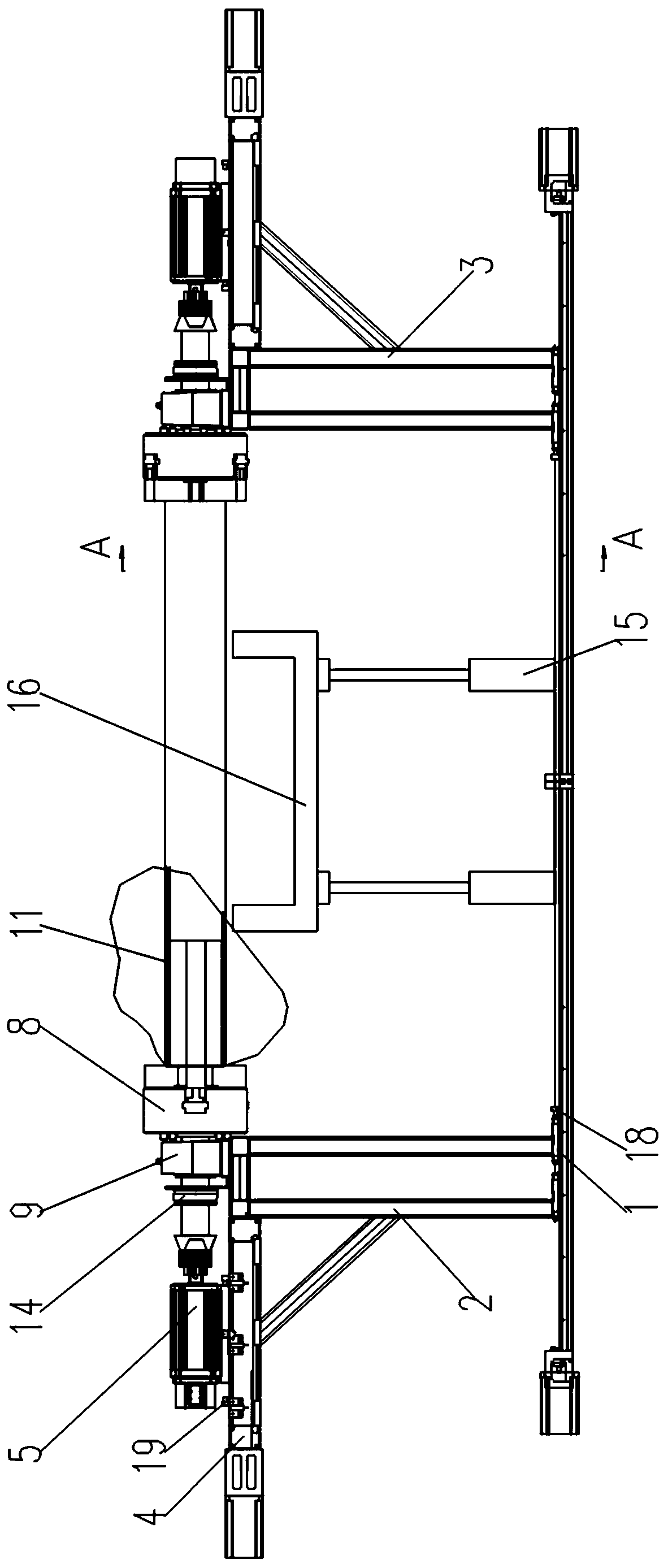

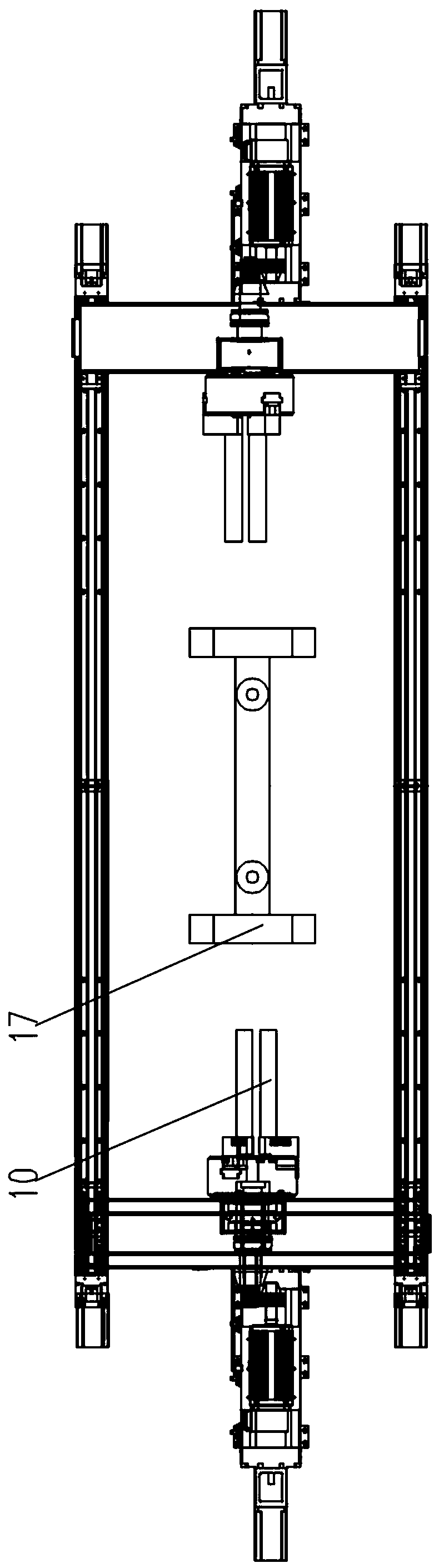

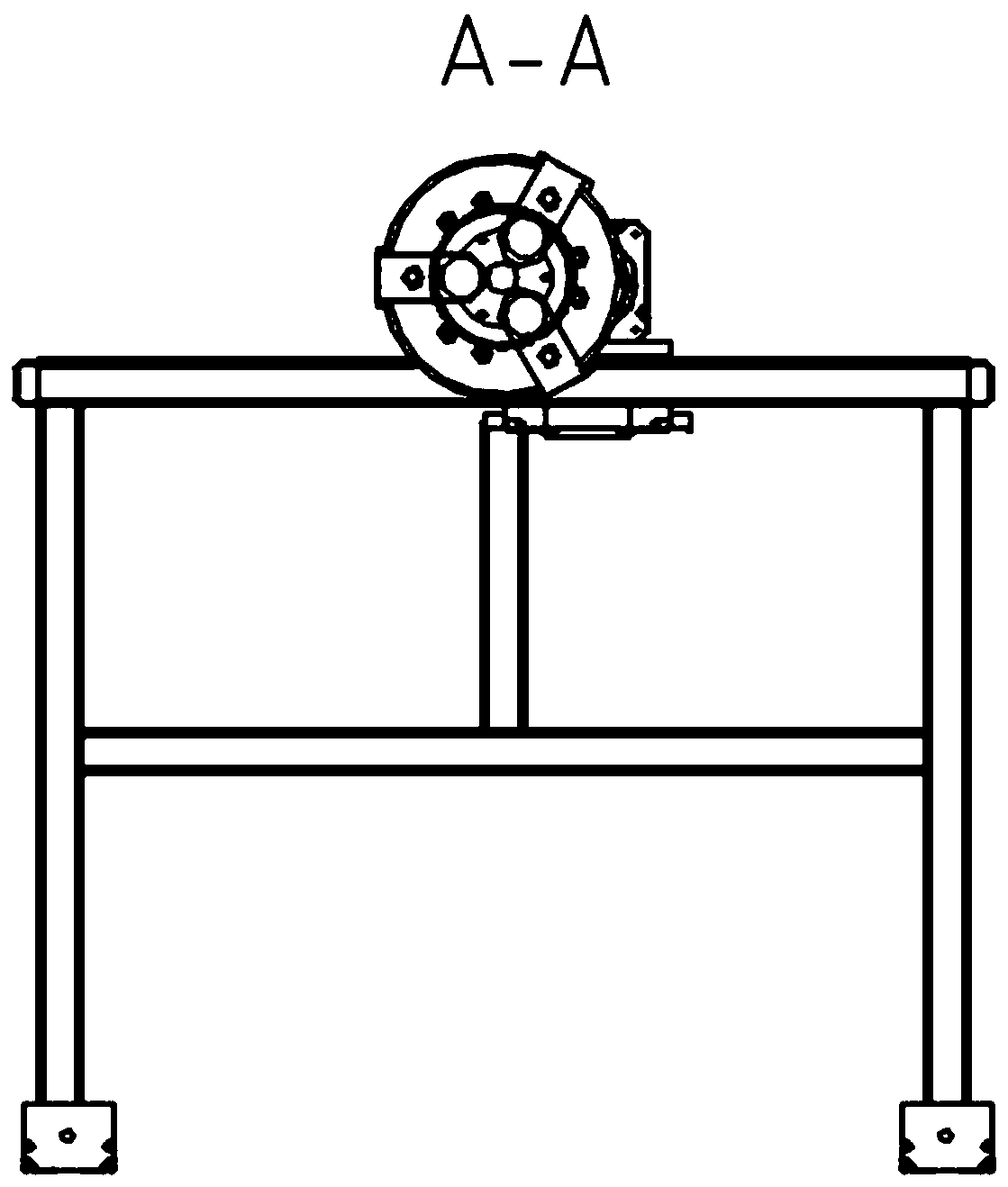

[0027] Such as Figure 1-5 As shown, the laminated glass adhesive film winding system provided by the present invention includes a main supporting mechanism, an auxiliary supporting mechanism, a power mechanism and a locking mechanism.

[0028] The main support mechanism includes a track assembly 1 installed on the ground, and the track assembly is a KK60 standard linear module and includes a stepping motor. The left frame 2 and the right frame 3 are respectively fixed on the left and right ends of the track on the track, and the sliding table assembly 4 is respectively installed above the left frame and the right frame. The sliding table assembly is an MSY110 aluminum-based series linear module and Includes motor.

[0029] The power mechanism includes a servo reduction motor 5 installed on the slider in the sliding table assembly. The output shaft of the servo reduction motor is equipped with a main spur gear 6-1 and a main bevel gear 7-1. Specifically, the main spur gear, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com