Steel wire pay-off device

A technology of pay-off device and steel wire, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of single-wire arching of stranded conductors, reducing production efficiency, and uneven tension. The effect of popularization and easy operation, improving production efficiency and uniform pay-off tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

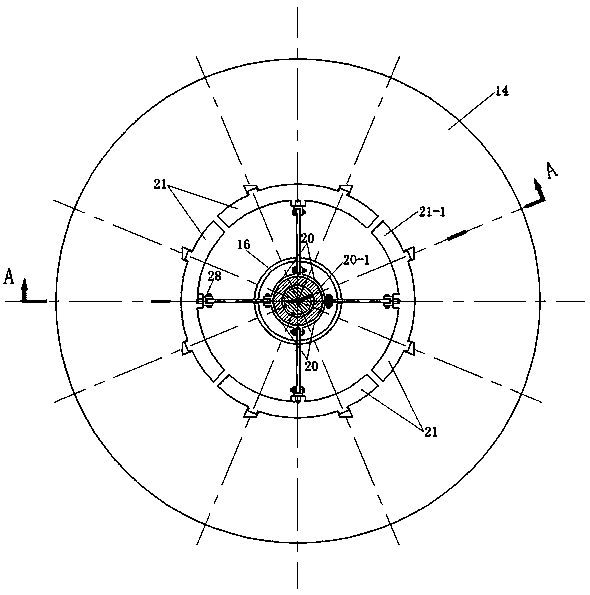

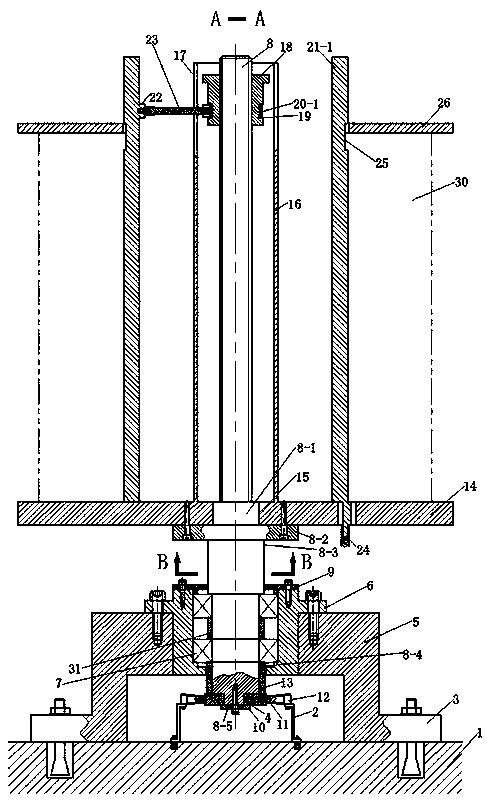

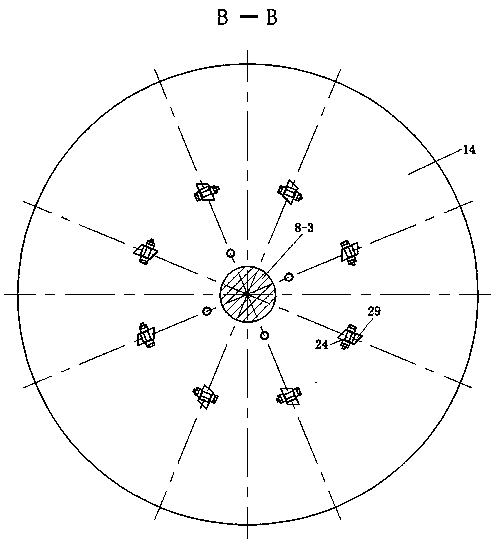

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-4 As shown, a wire pay-off device provided by the present invention includes a fixed seat 5 and two brackets 2 installed inside the fixed seat 5, a bearing seat 6 is installed in the fixed seat 5, and two sets of upper and lower sets are installed in the bearing seat 6. Tapered roller bearings 7, a second spacer sleeve 31 is installed between the two sets of tapered roller bearings 7. Bearing seat gland 9 is installed above the tapered roller bearing 7 on the bearing seat 6; a main shaft 8 is pierced inside the tapered roller bearing 7, and the main shaft 8 is divided into primary shafts 8 sharing the same center line from top to bottom -1, the secondary shaft 8-2, the tertiary shaft 8-3, the fourth shaft 8-4 and the fifth shaft 8-5, the bottom of the fifth shaft 8-5 is equipped with a tension disc 11 through the tension disc gland 10, A DB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com