Curtain wall structure, curtain wall plate fixing device and curtain wall installation method

A technology for fixing devices and curtain wall panels, applied in the direction of walls, building components, building structures, etc., can solve the problems of mutual dislocation, weak rigidity of inorganic quartz stone curtain wall panels, affecting the smoothness and beauty of the outer surface of the curtain wall, etc., to achieve convenient installation, The effect of smoothing the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

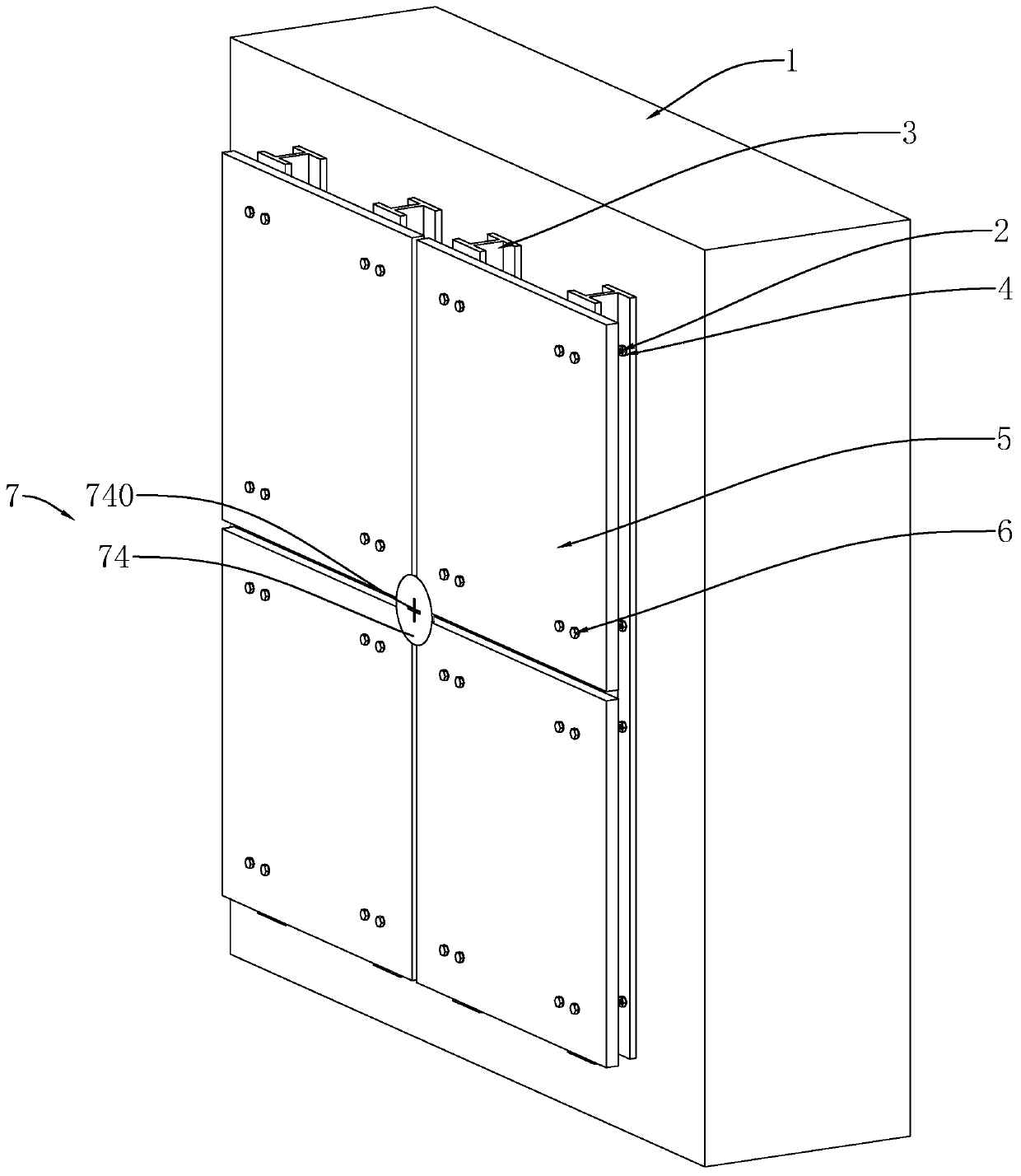

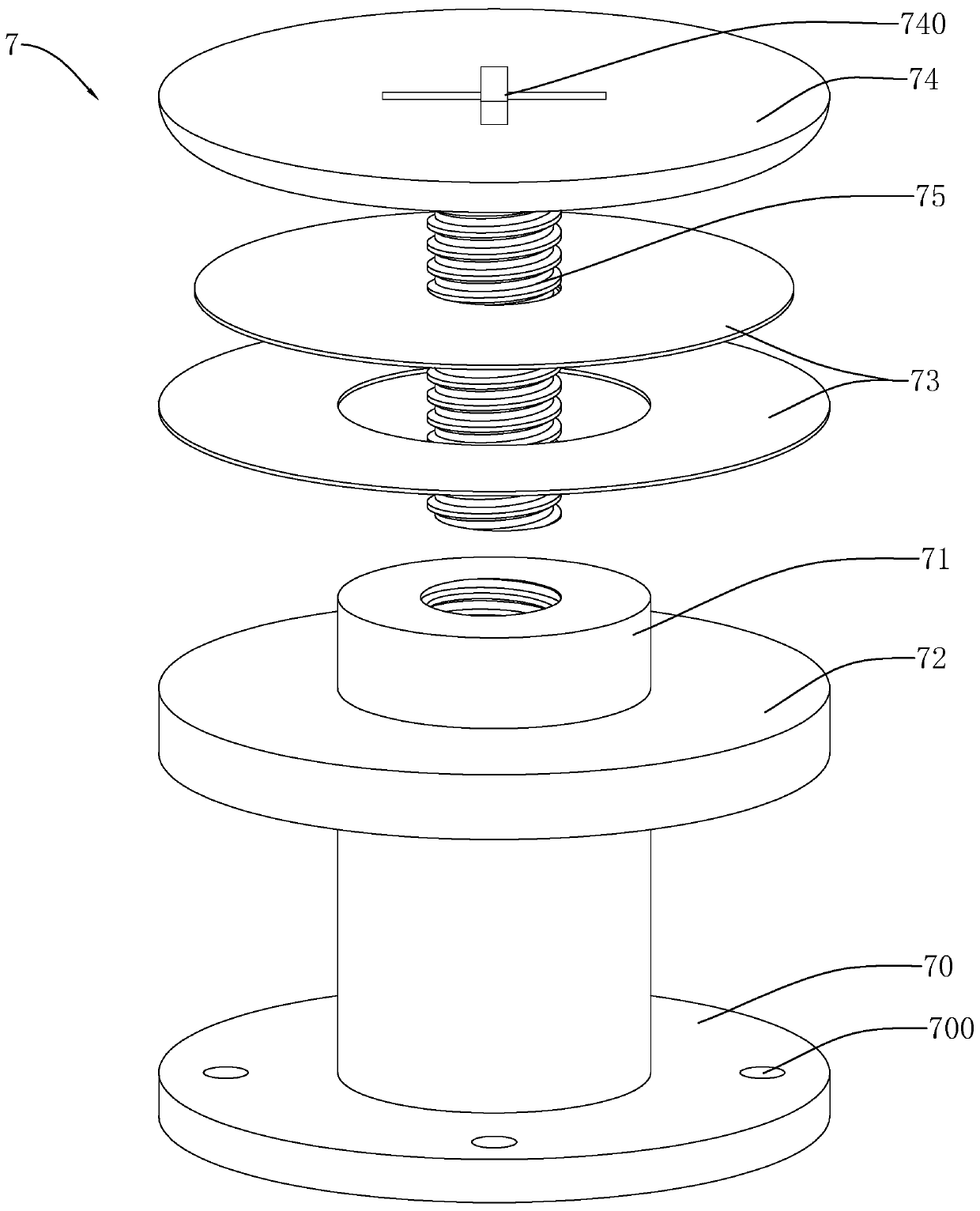

[0041] refer to figure 1, is a curtain wall structure disclosed by the present invention, comprising a wall body 1, embedded screws 2, H-shaped steel 3, nuts 4, curtain wall panels 5, fixing bolts 6 and fixing devices 7; there are multiple embedded screws 2, multiple The pre-embedded screw 2 is arranged in a rectangular array, part of the body of the pre-embedded screw 2 is buried in the wall 1, and a part protrudes from the surface of the wall 1; there are multiple H-shaped steel 3, and the multiple H-shaped steel 3 is vertically arranged and connected to the pre-embedded Corresponding to the screw 2; there are multiple nuts 4 and are compatible with the embedded screw 2; the embedded screw 2 passes through the wing plate of the H-shaped steel 3 and is screwed to the nut 4; there are multiple curtain wall panels 5, and the curtain wall panels 5 are rectangular panels. The curtain wall panel 5 is set on the wing plate of the H-shaped steel 3 away from the wall 1; there are mu...

Embodiment 2

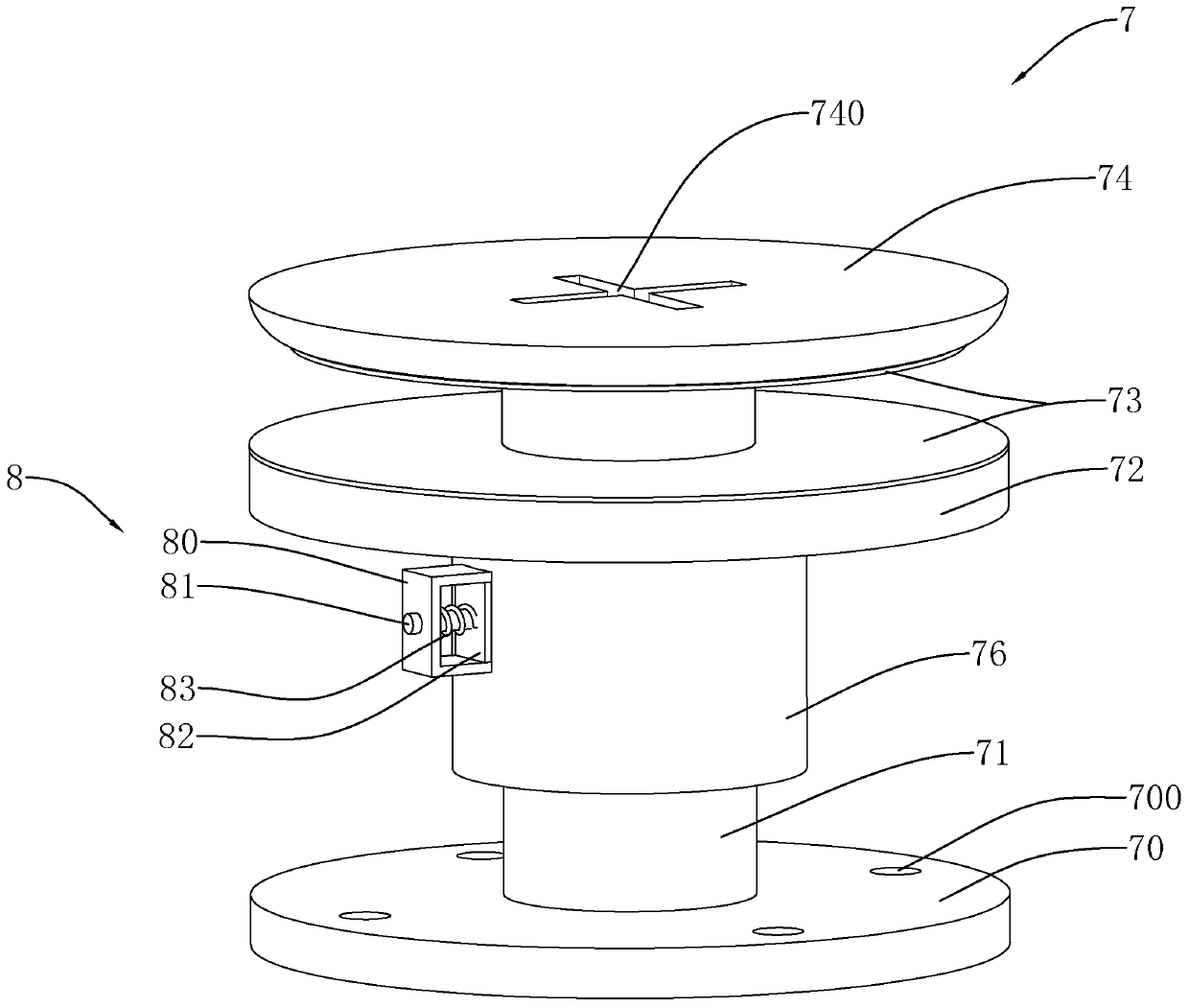

[0045] In actual use, the thickness of the curtain wall panel 5 changes with the height of the building. A thinner curtain wall panel 5 is required within the height range of 15 meters or less, and a medium curtain wall panel 5 is used within the height range of 15 meters to 45 meters. A thicker curtain wall panel 5 is selected for a height of more than fifteen meters; the gap between the receiving plate 72 and the pressure plate 74 on the fixing device 7 is fixed, which will not be applicable to the selected curtain wall panel 5 for each height range.

[0046] refer to Figure 4 , the difference between this embodiment and Embodiment 1 is that the present invention further designs the limiting groove 710, the sleeve 76 and the insurance component 8; The slots 710 are horizontally provided on the side walls of the threaded cylinder 71 and correspond up and down. The upper limit slot 710 corresponds to the thinner curtain wall panel 5 selected for a height of less than fifteen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com