Wiping mechanism for clean type leveling device with rotating speed early warning function

A horizontal device and clean technology, which is applied in the field of wiping mechanism for clean horizontal devices, can solve problems such as loose joints, early warning prompts of the drive motor, and excessively high speed of the drive motor, so as to achieve a firm and stable looseness that is not easy to loosen. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

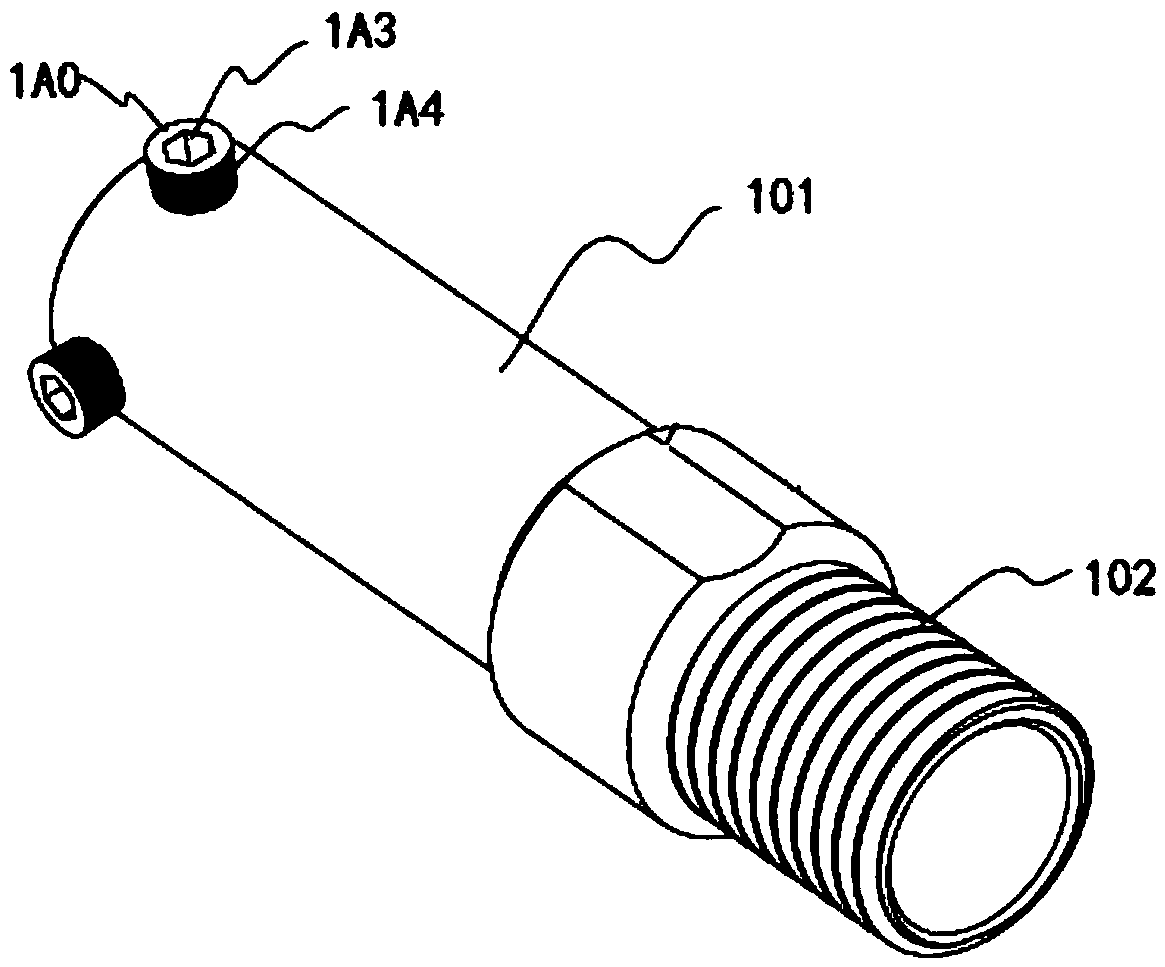

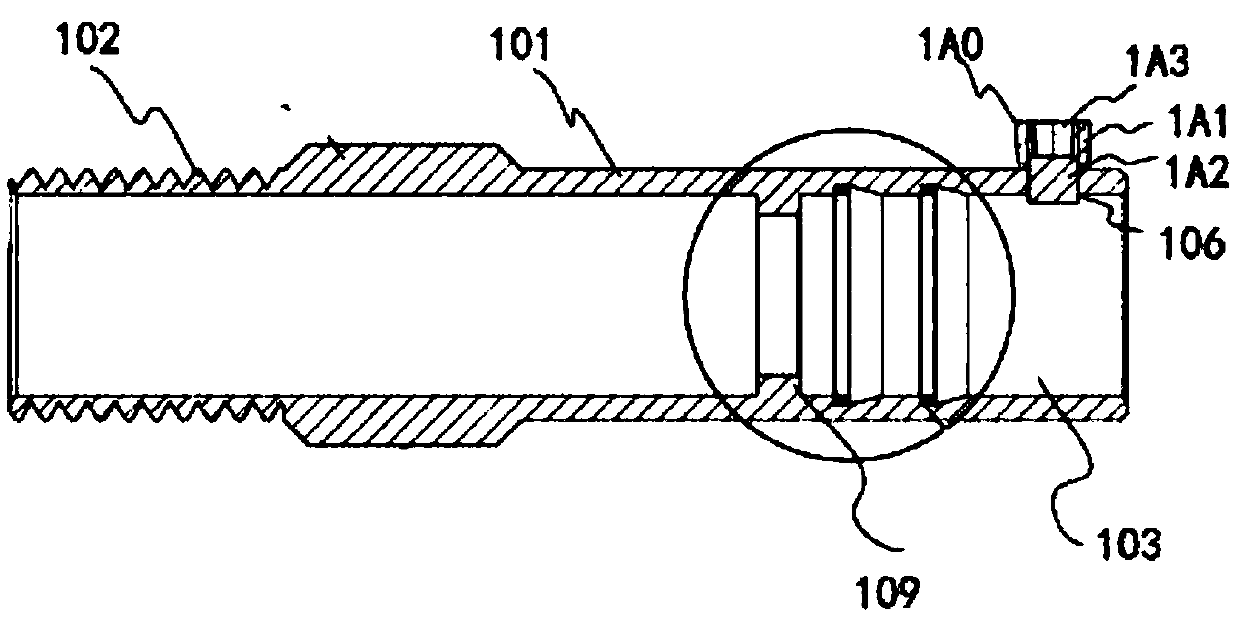

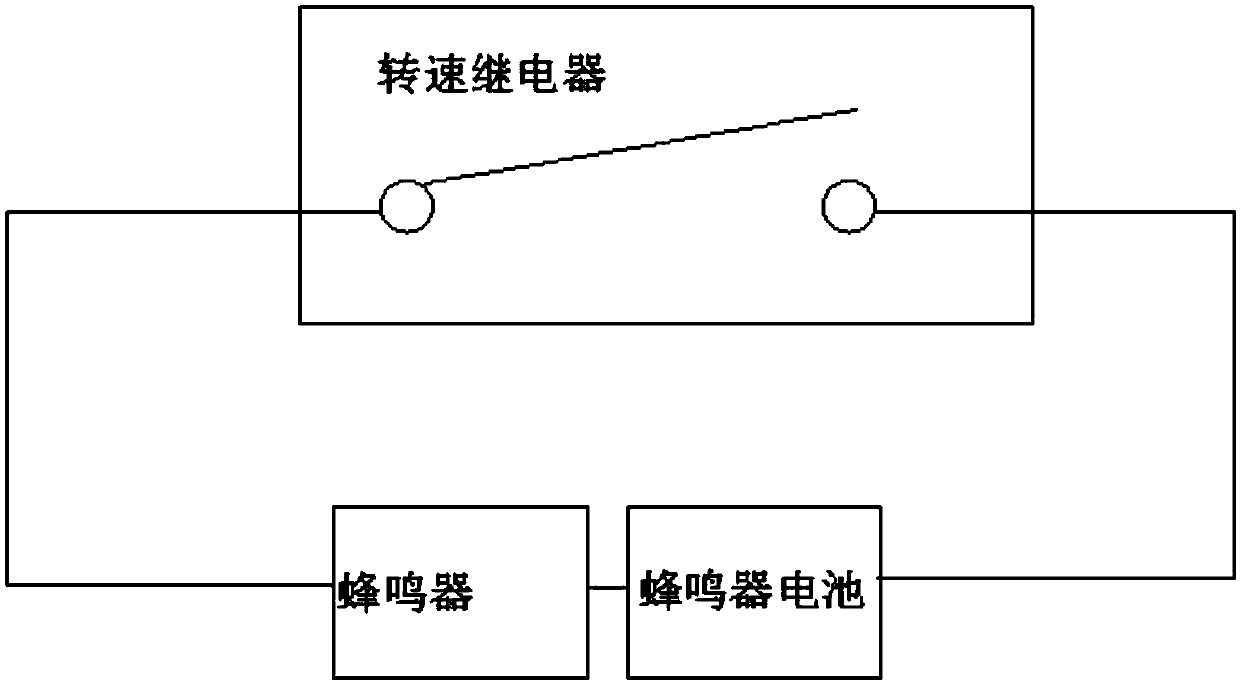

[0018] Such as Figure 1-Figure 3 As shown, the clean horizontal device with speed warning includes the self-cleaning water meter as described in the application number "201721801751.9", the application date is "2017.12.21" and the patent name is "self-cleaning water meter"; the self-cleaning water meter Including the water meter, the water meter is provided with a glass surface, one side of the glass surface is provided with a vertical rotating shaft, a cover is sleeved on the rotating shaft, the cover rotates horizontally around the rotating shaft, a cavity is provided under the cover, and a There are upper and lower rows of mounting seats, and a wiping mechanism is set between the upper and lower rows of mounting seats. The wiping mechanism includes two spindles, one spindle is located on the upper row of mounting seats, and the other is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com