Overhaul system for three-dimensional variable-cross-section A-shaped inclined steel box main tower and control method thereof

A technology of variable section and main tower, applied in bridge maintenance, bridge parts, erection/assembly of bridges, etc., can solve problems such as damage to the surface paint of the inclined main tower, difficult to control the construction period, and increase in the cost of erecting brackets. The form is firm and reliable, the construction method is simple, and the effect is easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

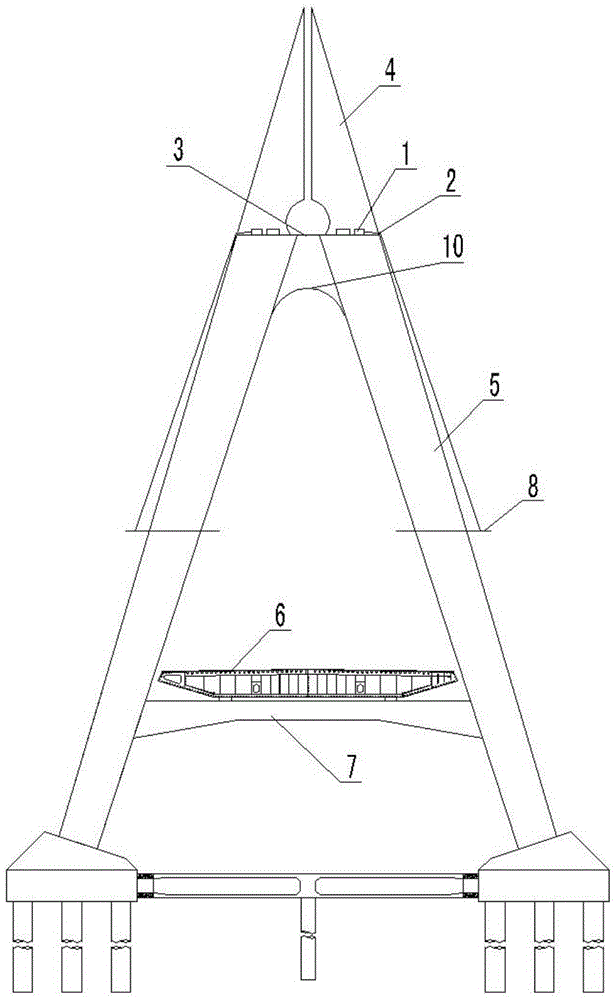

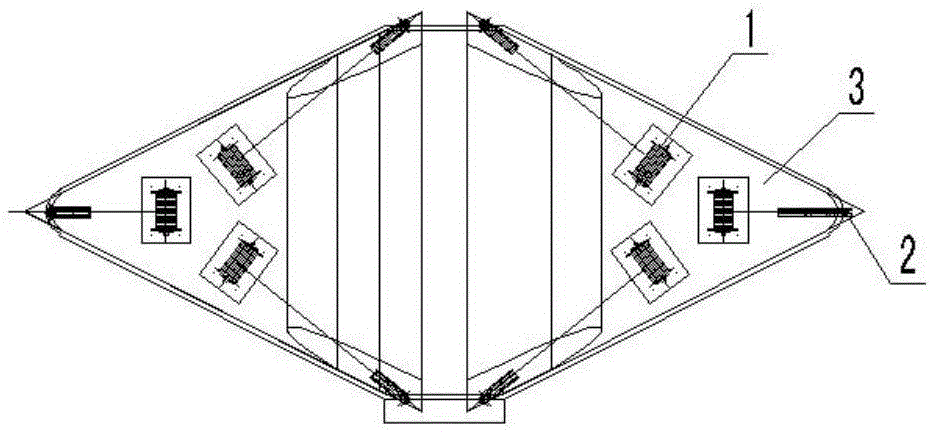

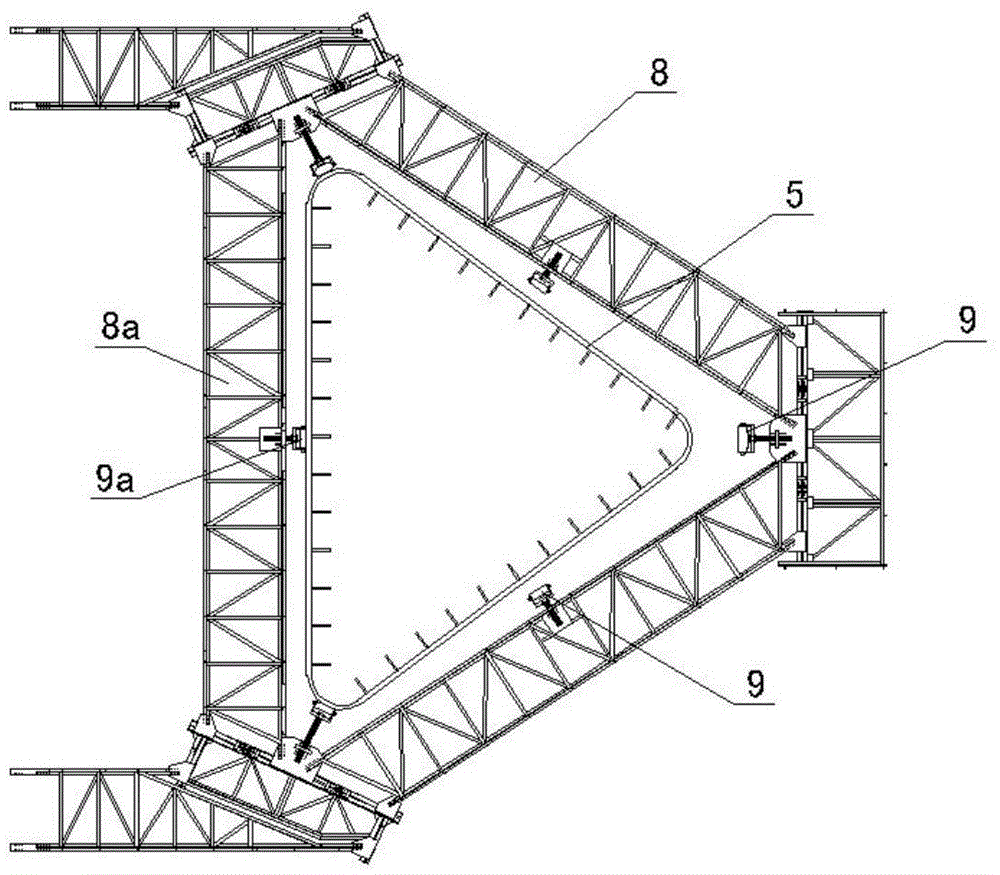

[0022] see figure 1 , figure 2 , image 3 with Figure 4 In this embodiment, the three-dimensional variable cross-section A-shaped inclined steel box main tower maintenance system is to arrange the hoist 1 on the tower crown bottom plate 3 of the three-dimensional variable cross-section A-shaped inclined steel box main tower, and the steel wire rope of the hoist 1 is arranged on the tower crown bottom plate 3 The guide fixed pulley 2 on the edge of the main tower passes through the side wall plate of the main tower body 5, and is used to promote the maintenance platform 8 attached to the periphery of the tower body through the rubber roller 9; The following tower body sections walk along the tower body; the rubber rollers 9 are fixedly connected on the maintenance platform by screws, and the length of the screw rods can be adjusted so that each rubber roller 9 can be attached to the periphery of the main tower body 5; for the A-shaped tower , use the hoist 1 to slowly lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com