Direct-type partition display backlight source

A partitioned display, direct type technology, applied in the field of backlight, can solve the problem of not meeting the needs of consumers, and achieve the effect of excellent display function, reliable and stable structure, and improved light utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

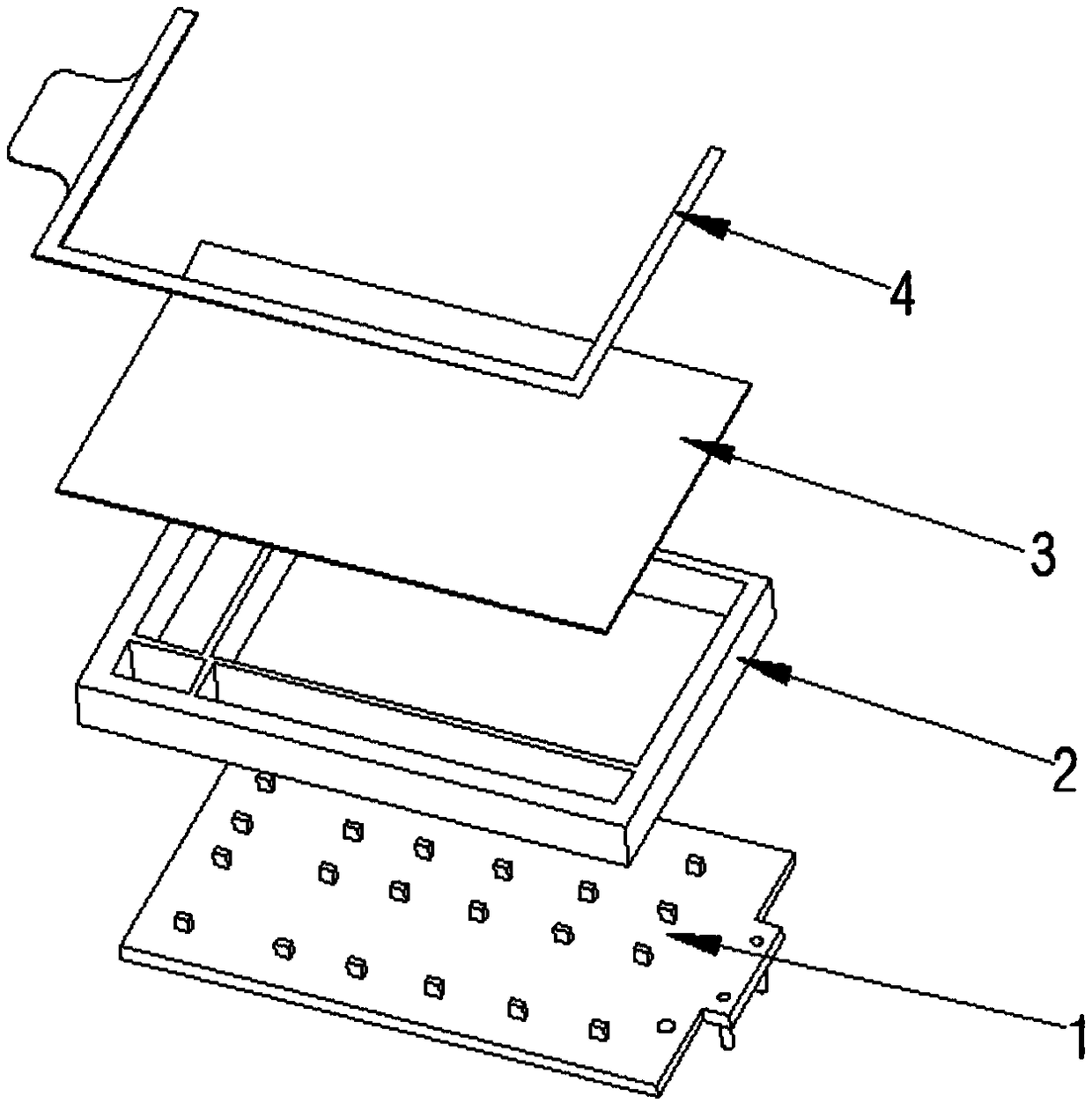

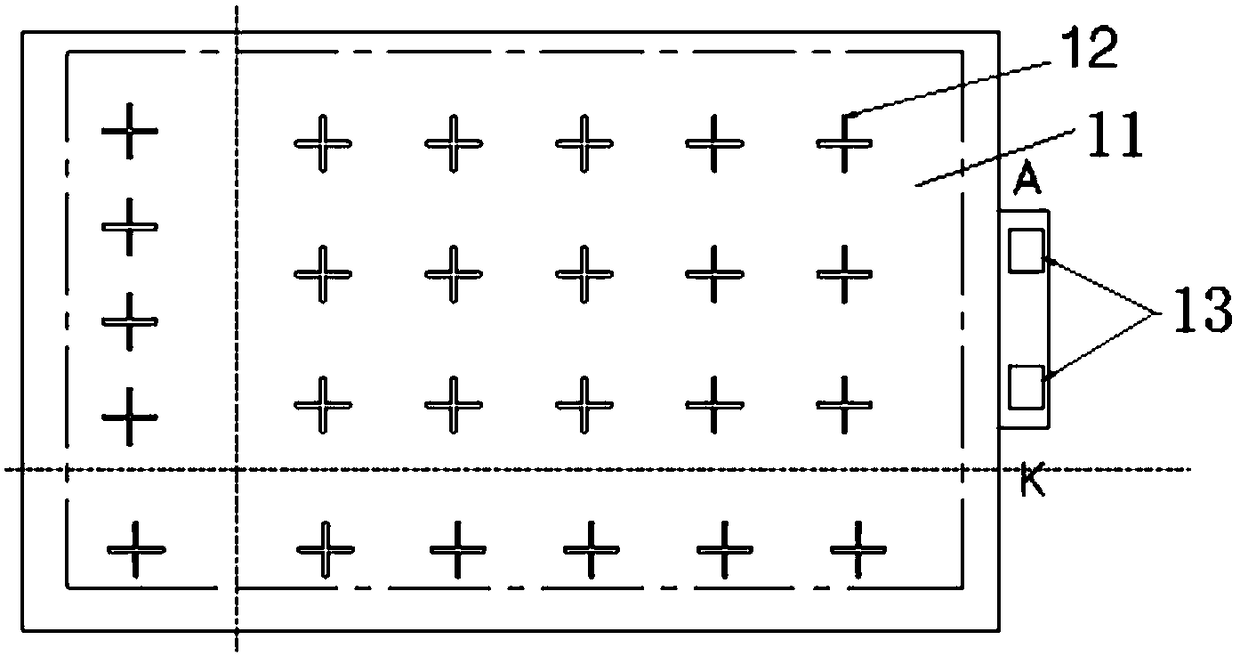

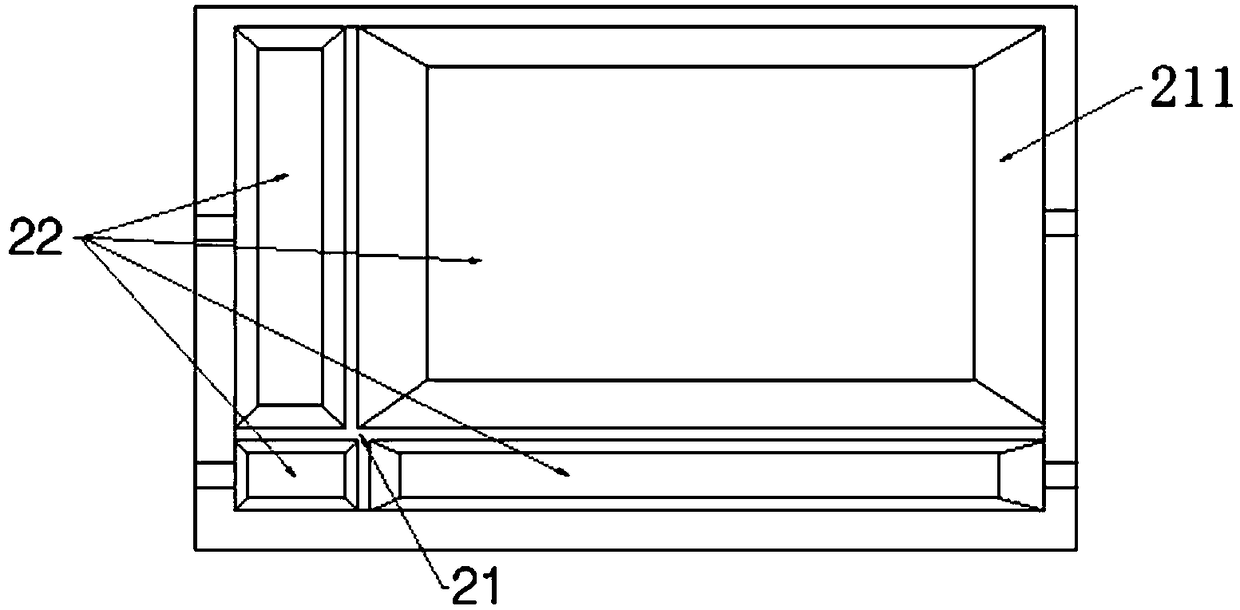

[0020] The embodiment of the present invention provides a direct type partitioned display backlight, and its structural explosion diagram is as follows figure 1 As shown, it includes a PCB base plate 1 assembled from bottom to upper level, a medium plastic shell 2, a diffuser film 3, and a black and white single-sided adhesive 4. The PCB base plate 1 is divided into a preset area 11, and each of the preset areas 11 is provided with an independent drive circuit and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com