Stirring structure for production

A technology of agitating shaft and agitator, which is applied to mixer accessories, dissolving, mixers, etc., can solve problems such as excessive heat accumulation of server chassis during server working cycle, spontaneous combustion of server, and difficulty in maintaining the upper wall of server chassis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

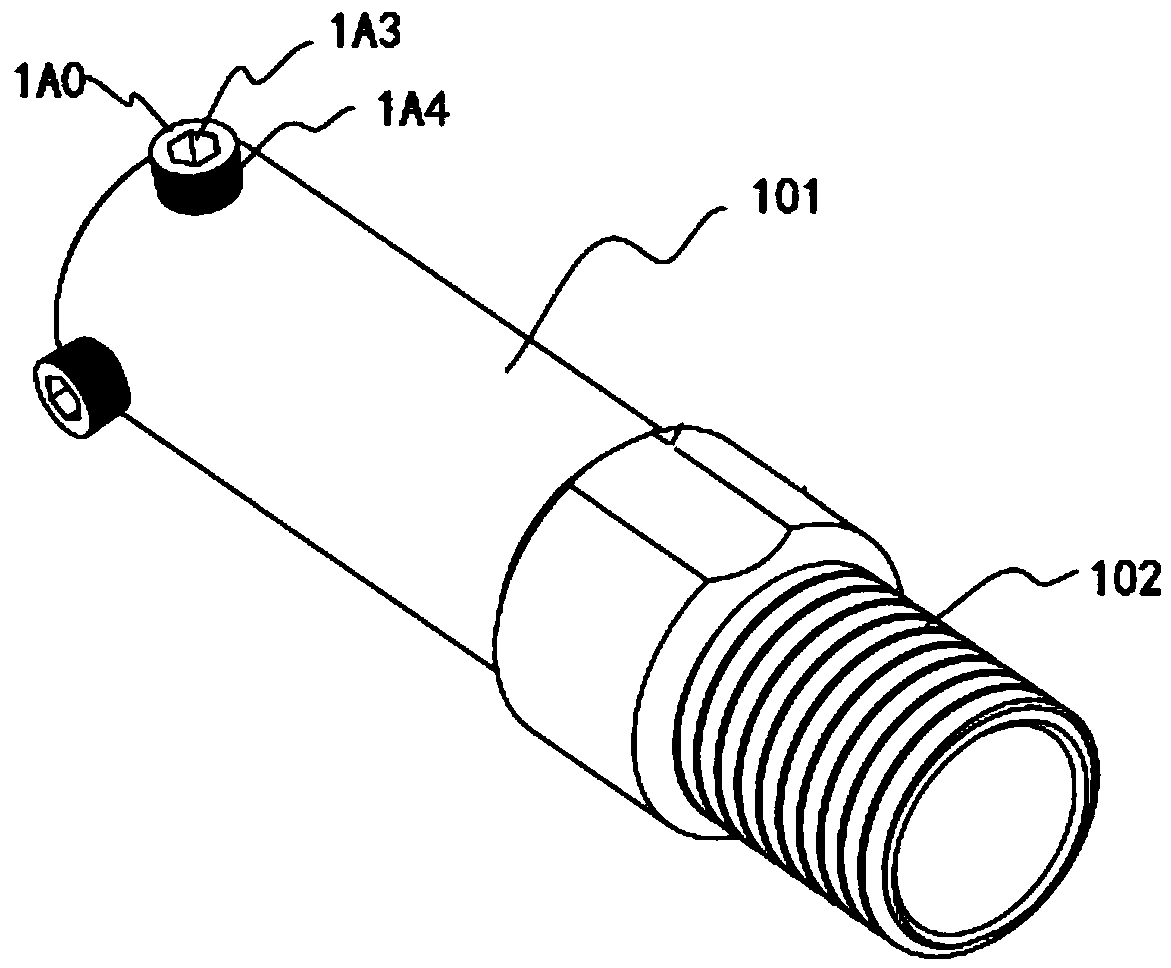

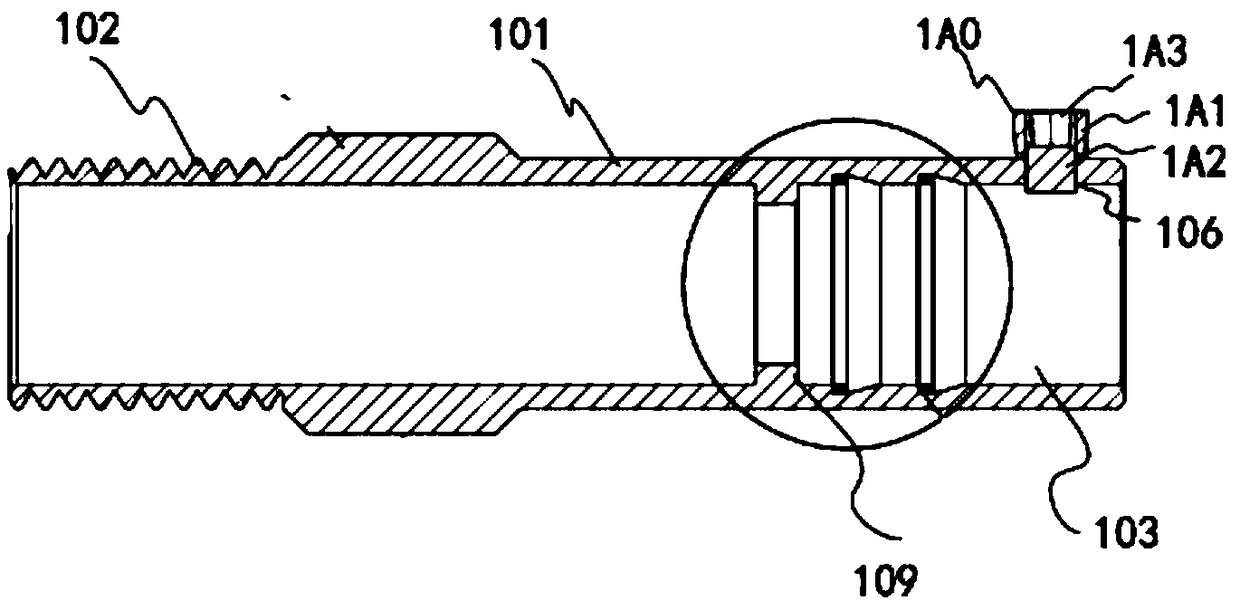

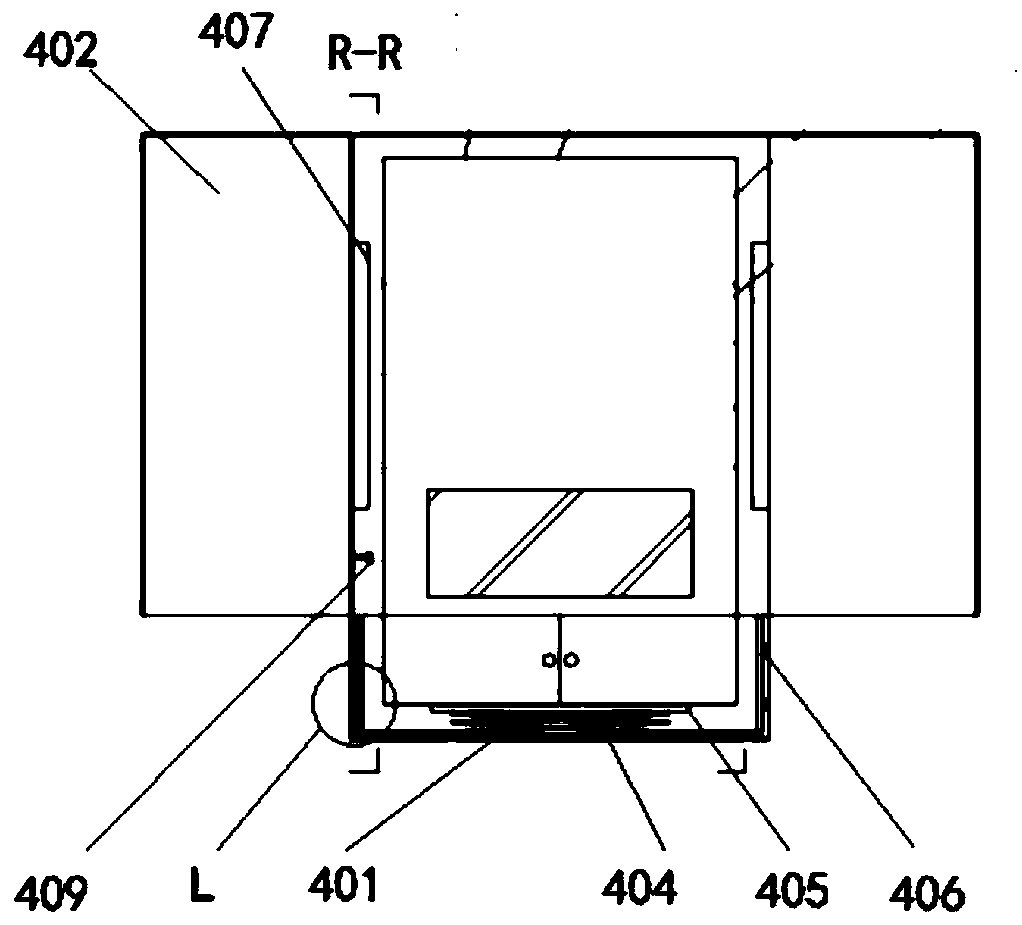

[0044] Such as Figure 1-Figure 5 As shown, the stirring structure for production includes the low-speed stirring device for paint production as described in the application number "201721437981.1", the application date is "2018.07.12" and the patent name is "a low-speed stirring device for paint production";

[0045] The low-speed stirring device for coating production includes a stirrer, a mixing bucket, and a fixed support. The stirrer includes a low-speed motor, a stirring shaft, and a stirring blade. The top of the stirring shaft is connected to the low-speed motor. The stirring blade is connected, the stirring shaft is installed inside the mixing barrel; the fixing bracket is arranged at the lower part of the mixing barrel, and both sides of the fixing bracket are provided with fixing plates, and the fixing plates There is a fixed hole on the top, the bottom of the mixing tank is provided with a discharge port, the top of the mixing tank is provided with a feeding port, ...

Embodiment 2

[0054] Such as Figure 1-Figure 5 As shown, the stirring structure for production includes the low-speed stirring device for paint production as described in the application number "201721437981.1", the application date is "2018.07.12" and the patent name is "a low-speed stirring device for paint production";

[0055] The low-speed stirring device for coating production includes a stirrer, a mixing bucket, and a fixed support. The stirrer includes a low-speed motor, a stirring shaft, and a stirring blade. The top of the stirring shaft is connected to the low-speed motor. The stirring blade is connected, the stirring shaft is installed inside the mixing barrel; the fixing bracket is arranged at the lower part of the mixing barrel, and both sides of the fixing bracket are provided with fixing plates, and the fixing plates There is a fixed hole on the top, the bottom of the mixing tank is provided with a discharge port, the top of the mixing tank is provided with a feeding port, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com