Floating connector

A floating connector and connector technology, which is applied to vehicle connectors, connections, parts of connecting devices, etc., can solve the problem that the contacts in the connector cannot be floated, and achieve simple structure, convenient operation, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means and technical effects adopted by the present invention, the present invention will be described in detail below in conjunction with the examples.

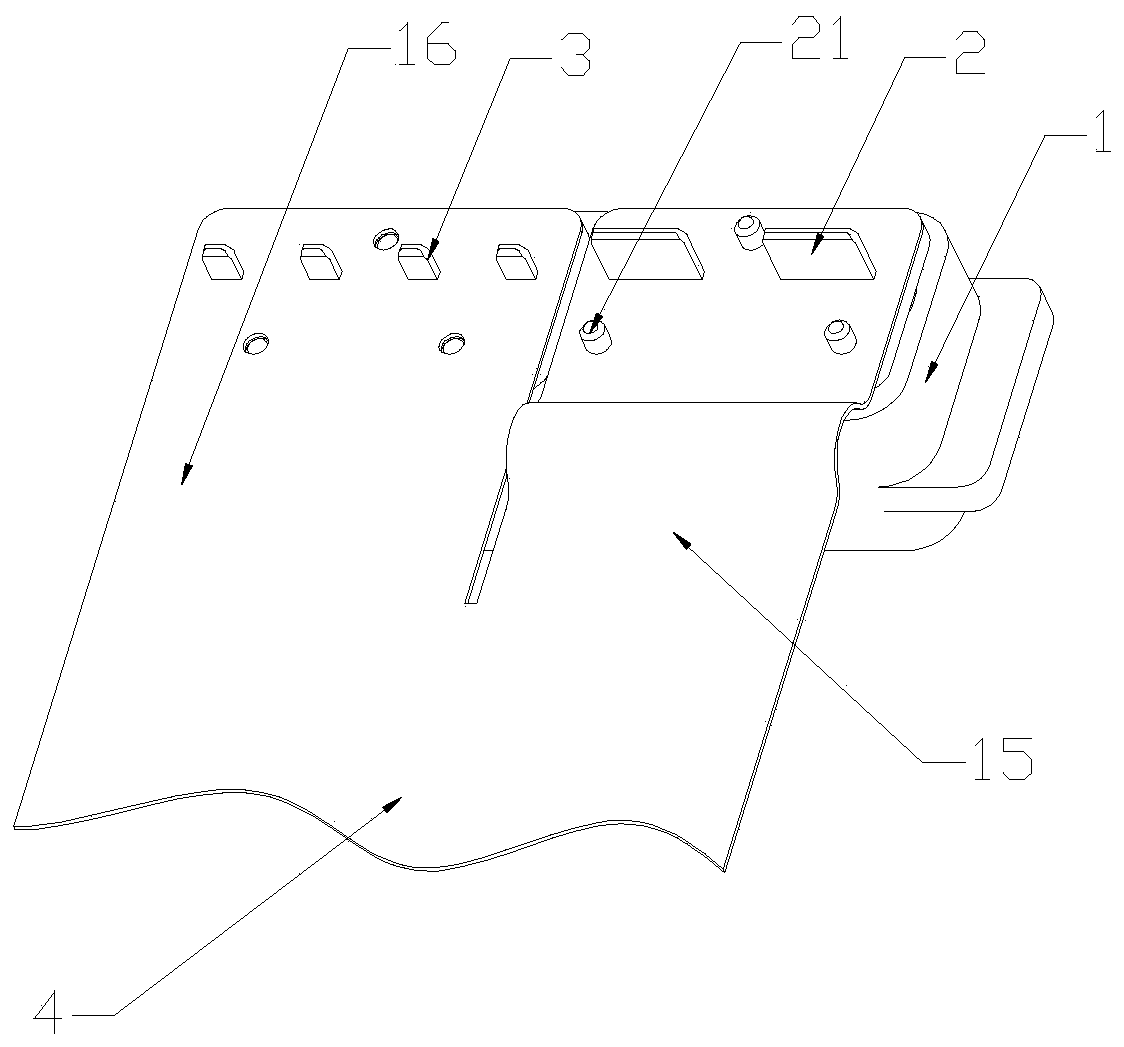

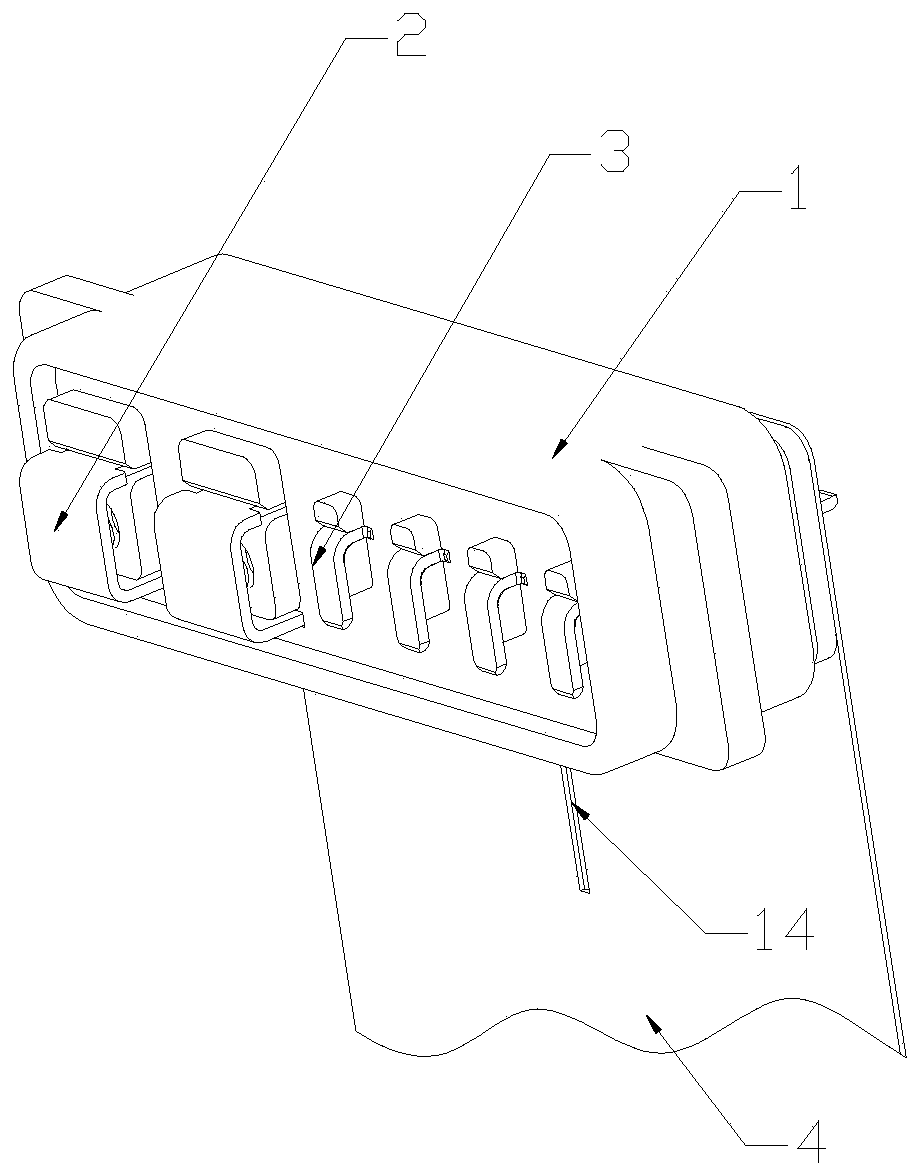

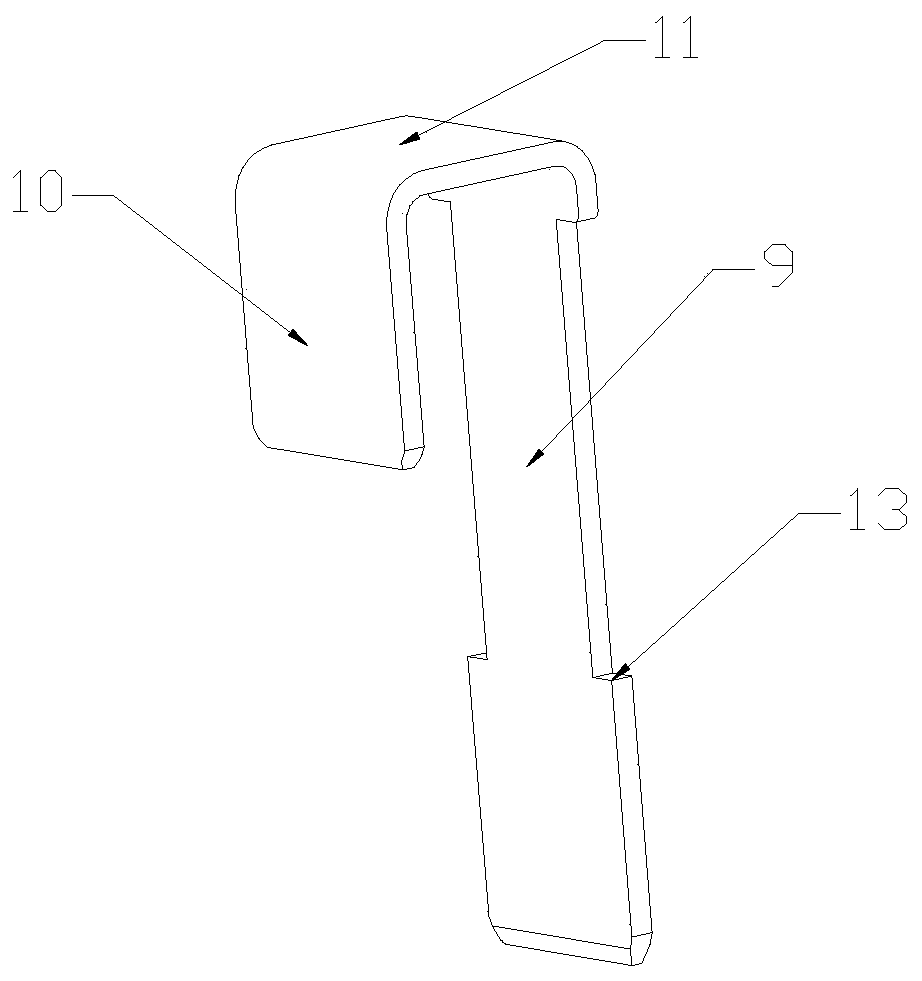

[0025] Such as figure 1 As shown, the floating connector of the present invention includes a connector housing 1, a power contact 2 and a signal contact 3 disposed in the connector housing, and a flexible board 4 welded to the power contact and the signal contact. The connector housing is provided with a first positioning groove 5 and a second positioning groove 6 for installing a power contact and an installation groove 8 for installing an elastic member 7, the installation groove is located between the first positioning groove and the second positioning groove, The power contact piece is U-shaped, including a first side 9, a second side 10 and a U-shaped surface 11 between the first side and the second side, the first side 9 of which is installed in the first positioning g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com