Packaging and shipping process for bridge crane spare parts

A technology for parts and processes, applied in the field of packaging and shipping of field bridge parts, can solve the problems of low manufacturability and poor standardization, and achieve the effect of small size, low cost, and protective packaging for the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

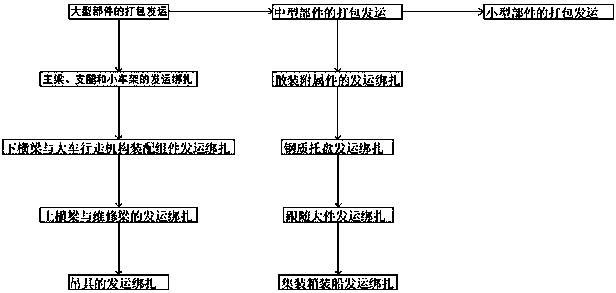

[0023] Such as figure 1 The specific packaging and shipping steps of a field bridge component packaging and shipping process shown are as follows: S1: packaging and shipping of large components; S2: packaging and shipping of medium-sized components; S3: packaging and shipping of small components.

[0024] S1: Packing and shipping of large parts; large parts include main beam, outriggers, lower beam, upper beam, maintenance beam, trolley frame, cart traveling mechanism and spreader.

[0025] S1.1: Delivery and binding of main beam, outriggers and trolley frame: Check the integrity of the tooling before delivery and binding of the main beam, outriggers and trolley frame to confirm that there is no abnormality. Use templates or rubber plates between the outriggers and the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com