Protecting structure of elevator safety supervision equipment

A technology for protecting structures and equipment, applied in electrical equipment casings/cabinets/drawers, electrical components, and modification with gaseous coolants, etc., can solve problems such as difficult equipment body protection, inability to withstand equipment body damage, etc., to prevent dust from entering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

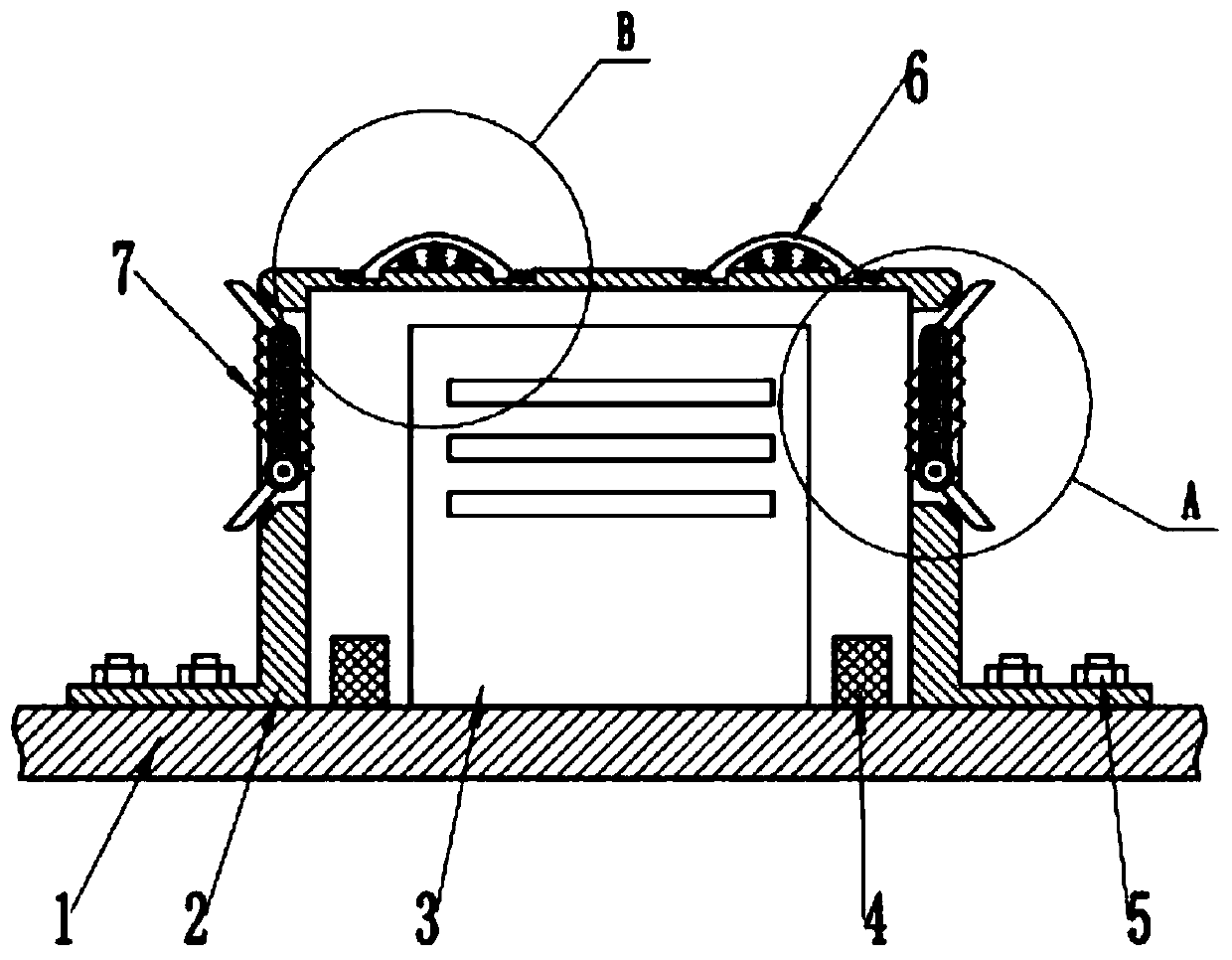

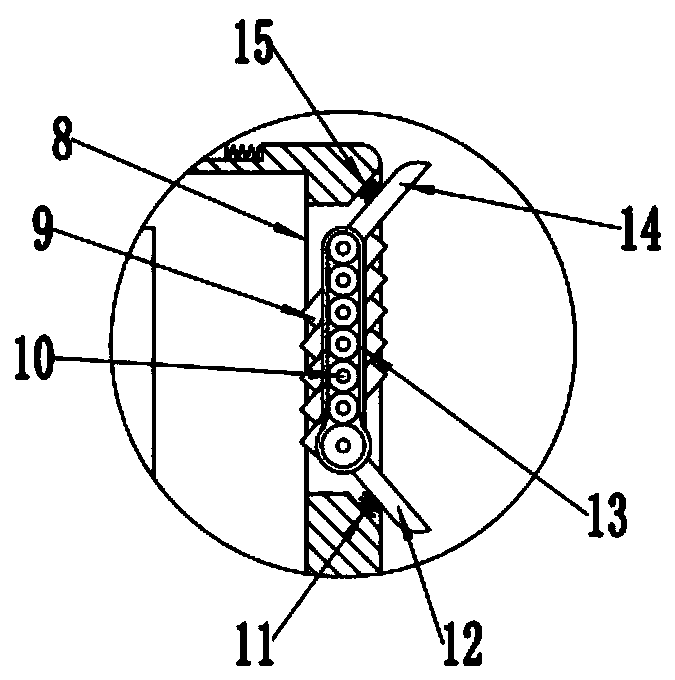

[0028] see Figure 1~3 , in an embodiment of the present invention, a protective structure for elevator safety monitoring equipment, including a protective cover 2 installed on the outside of the car body 1 and protecting the equipment body 3; the protective cover 2 is arranged on the outside of the equipment body 3, The side of the protective cover 2 is fixedly connected with the car body 1 by several fixing bolts 5;

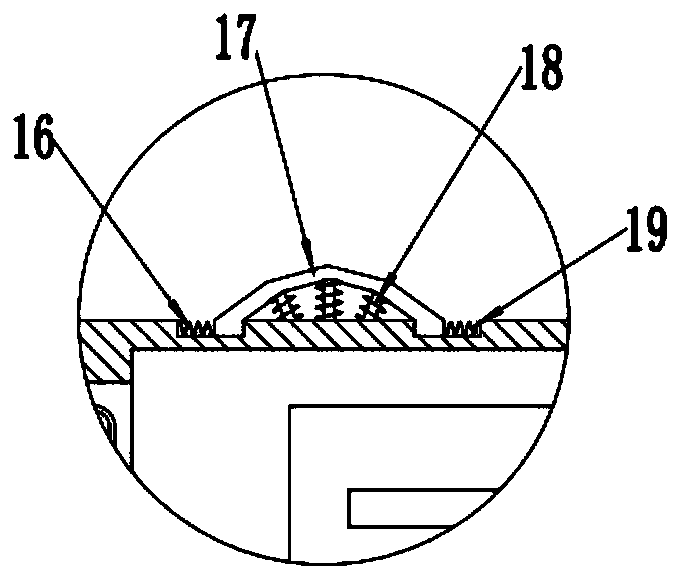

[0029] The top of the protective cover 2 is uniformly provided with several anti-collision mechanisms 6, and during the up and down operation of the elevator car body 1, the anti-collision mechanisms 6 are protected on the top of the protective cover 2, so as to prevent foreign matter inside the elevator shaft from damaging the protective cover 2. , and then damage the equipment body 3 inside the protective cover 2, the anti-collision mechanism 6 includes an anti-collision cover 17 with an arched structure, and the protective cover 2 is located on the left and ...

Embodiment 2

[0033] see Figure 4The difference between this embodiment and Embodiment 1 is that the inside of the protective cover 2 is fixedly installed with a dust-proof plate 20 inside the vent 8, and a number of filter holes are evenly opened on the dust-proof plate 20 for The air entering the inside of the protective cover 2 is filtered and dust-removed to prevent dust from damaging the device body 3 .

Embodiment 3

[0035] see Figure 5 The difference between this embodiment and Embodiment 1 is that a number of fixing bolts 5 are installed along the outer side of the protective cover 2 in descending order, so that the connection between the protective cover 2 and the car body 1 is more fixed. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com