Pit type lifting garage

A technology of pit type and garage, applied in the field of garages, can solve the problems of not being flexible enough, the use of garages is single, and the space cannot be saved well, so as to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

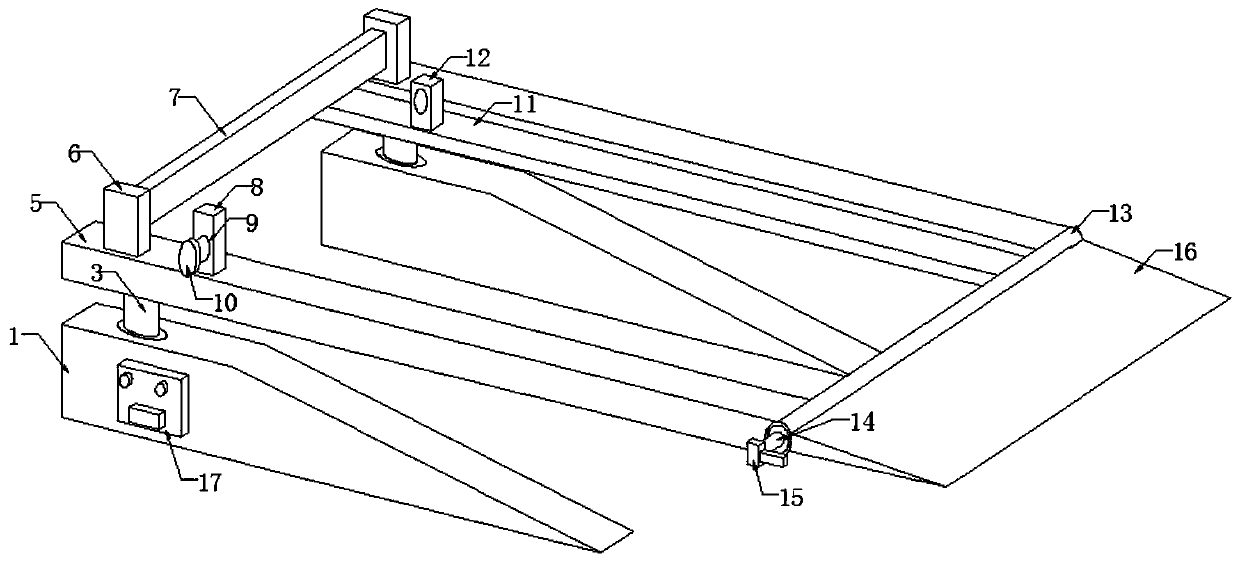

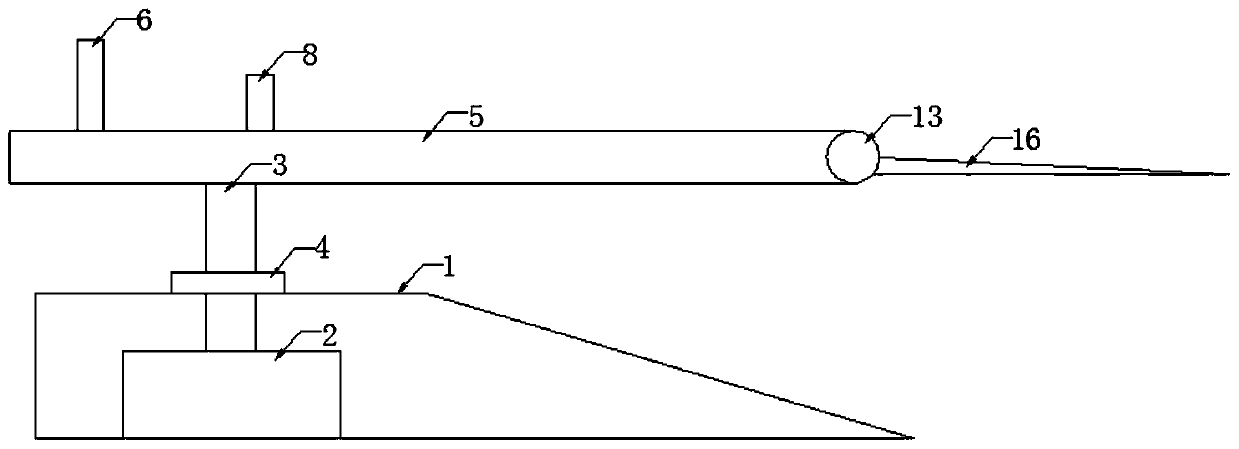

[0017] Such as Figure 1-2 As shown, a pit-type lift garage includes a base 1, a motor 2 is arranged inside the base 1, and an electric control telescopic rod 3 is connected to the top of the motor 2, and the electric control telescopic rod 3 drives the No. 1 plate 5 to move up and down. The top of the electric control telescopic rod 3 is fixedly connected with a No. 1 plate 5, and the top of the No. 1 plate 5 is provided with a vertical plate 6, and a baffle plate 7 is connected between the vertical plates 6 to prevent the vehicle from reversing too far. One side of the vertical plate 6 is provided with a fixed block 8 , the fixed block 8 is provided with a threaded column 9, the fixed block 8 is fixedly connected with the No. 1 handle 12 through the threaded post 9, and the inside of the No. 1 plate 5 is provided with a telescopic plate 11, and the telescopic plate 11 is provided with a No. 1 handle 12, No. 1 One end of the plate 5 is connected with a rotating shaft 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com