Heat energy recovery device and heat energy recovery process for dyeing waste liquid

A technology of heat energy recovery and dyeing waste liquid, applied in heat recovery systems, indirect heat exchangers, energy-saving heating/cooling, etc., can solve problems such as resource waste, save energy, save time and energy, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

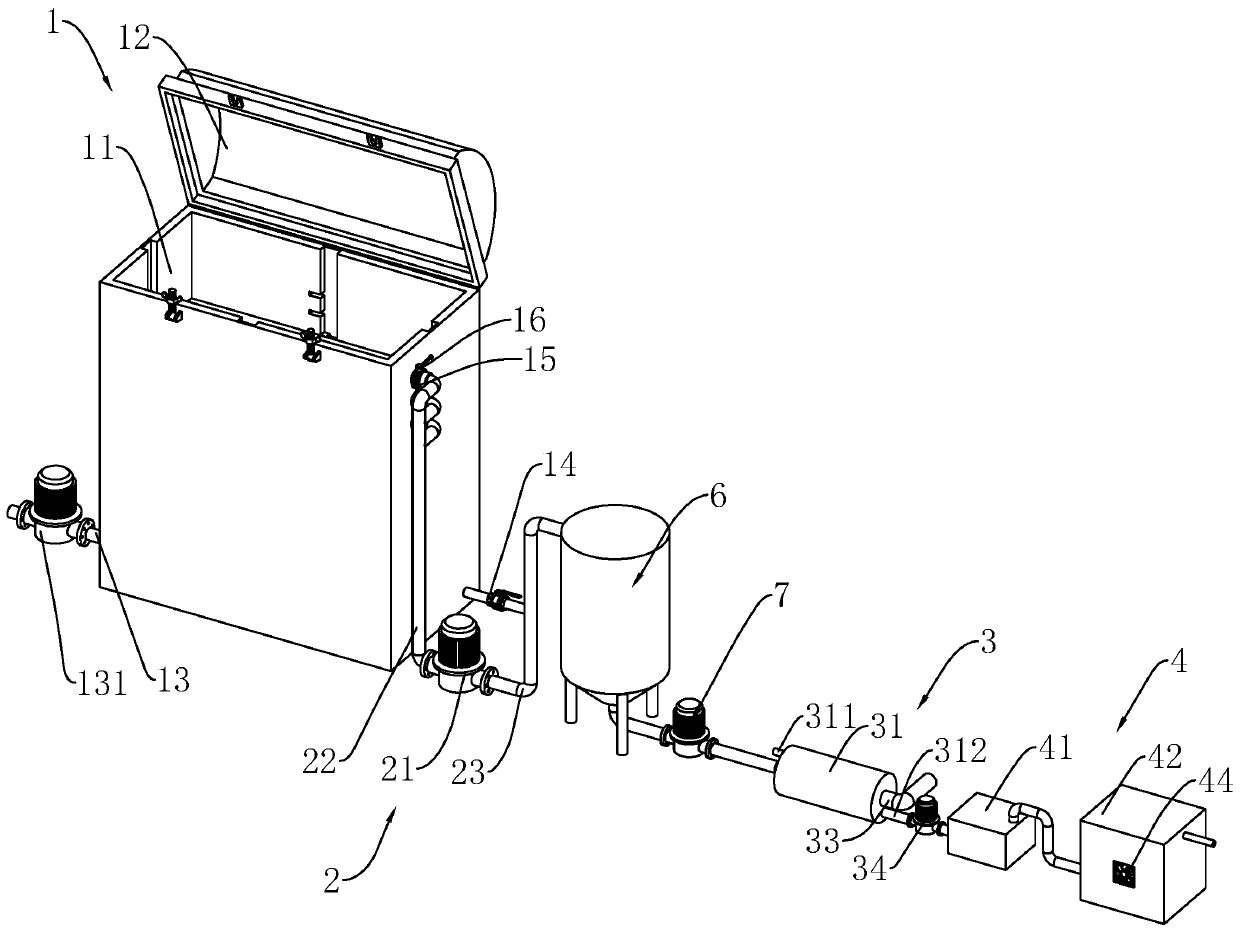

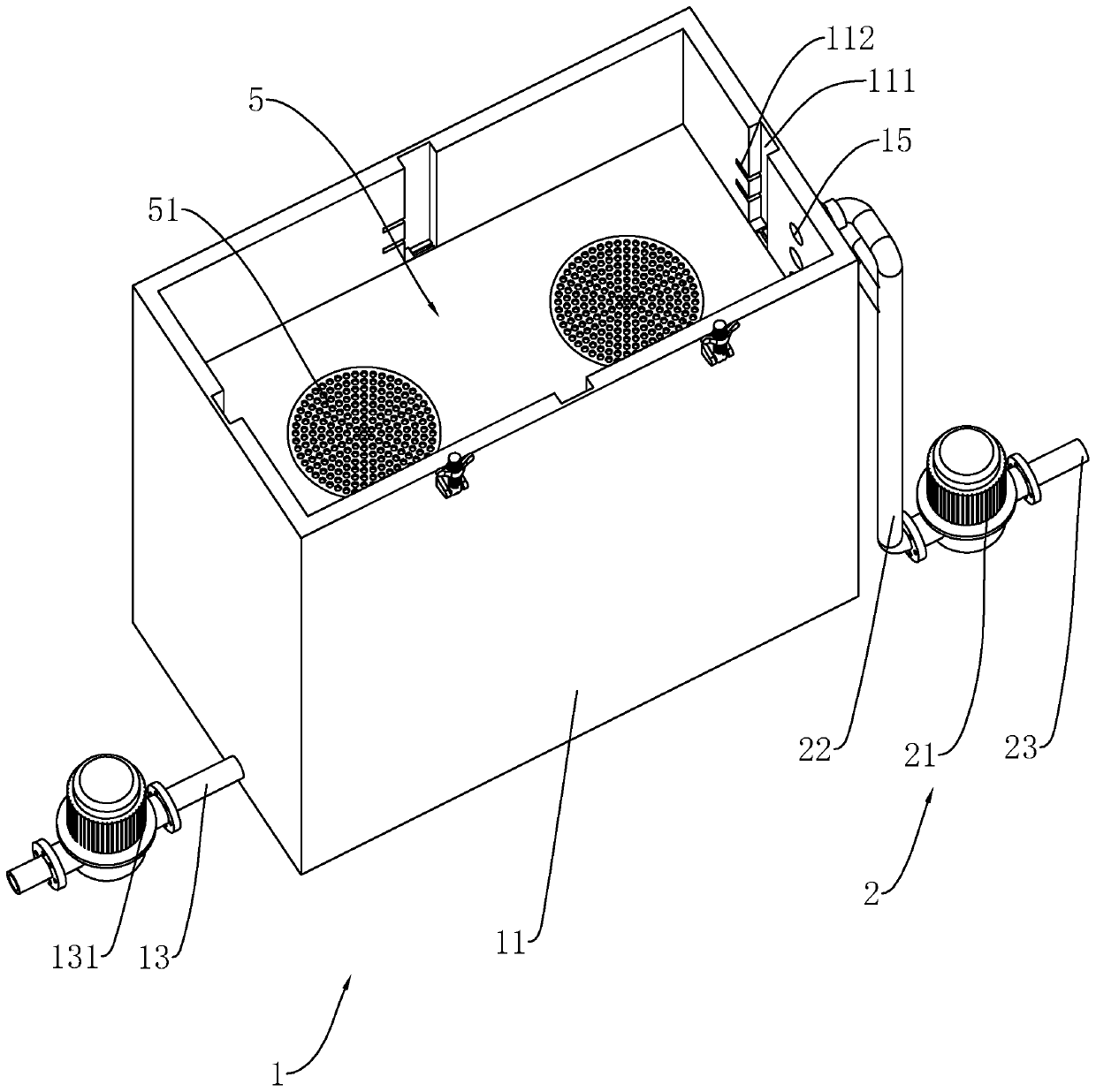

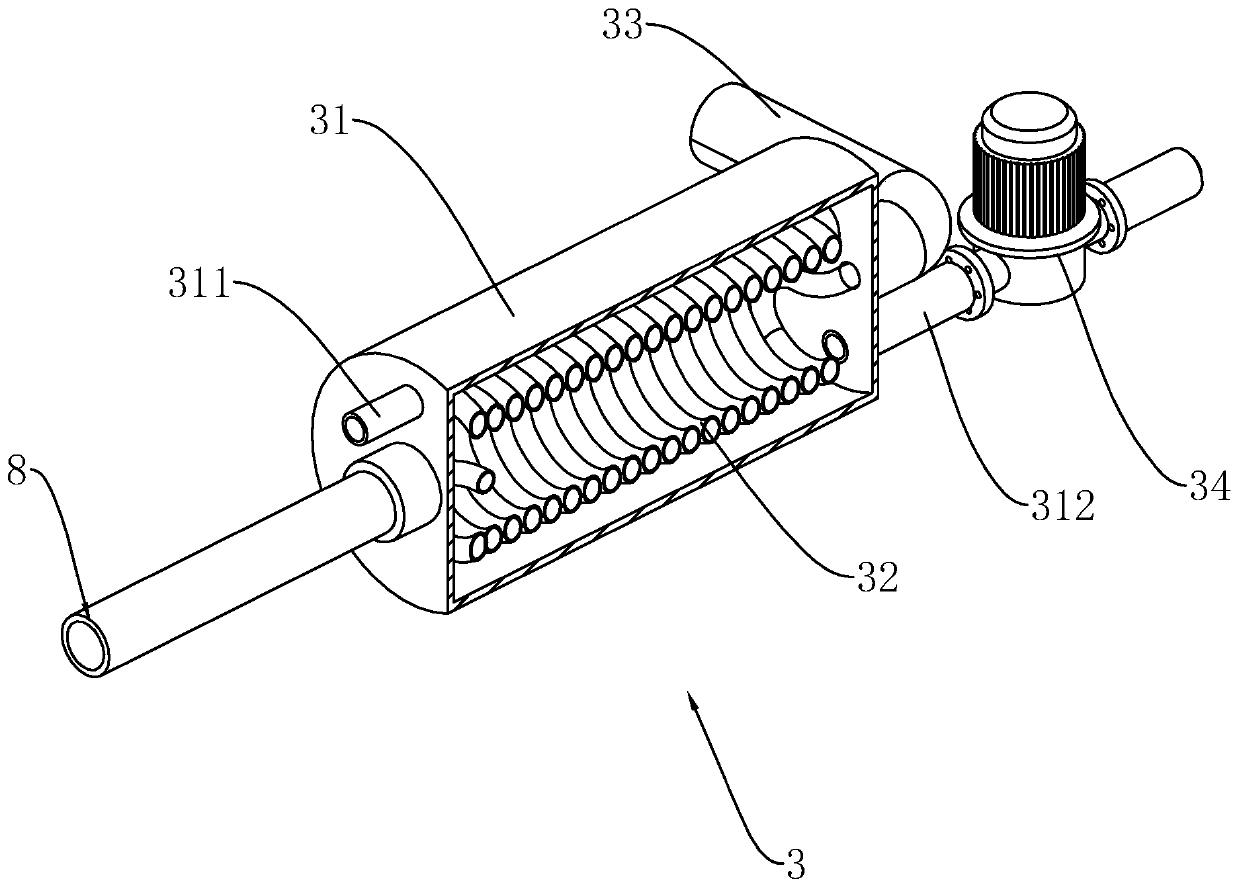

[0051] refer to figure 1 , a heat energy recovery device for dyeing waste liquid, including a dyeing box 1, a liquid pumping assembly 2, a heat exchange assembly 3 and a drying assembly 4; the dyeing box 1 is arranged on the ground to hold the dyeing liquid and dye the skein The liquid pumping assembly 2 is arranged on one side of the dyeing box 1, and its liquid inlet port communicates with the interior of the dyeing box 1 to extract the dye solution in the dyeing box 1; the heat exchange assembly 3 is arranged on one side of the pumping assembly 2 side, which communicates with the water outlet end of the pumping assembly 2, and passes water at normal temperature into the heat exchange assembly 3 to exchange heat with the high-temperature waste liquid, heats up the normal-temperature water, and recycles the heat energy in the high-temperature waste liquid; The drying component 4 is arranged on one side of the heat exchanging component, and it communicates with the heat exchan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap