Hot continuous rolling strip steel convexity prediction method based on gradient boosting tree model

A gradient boosting tree and strip crown technology, applied in design optimization/simulation, geometric CAD, etc., can solve problems such as difficult to further improve strip crown control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

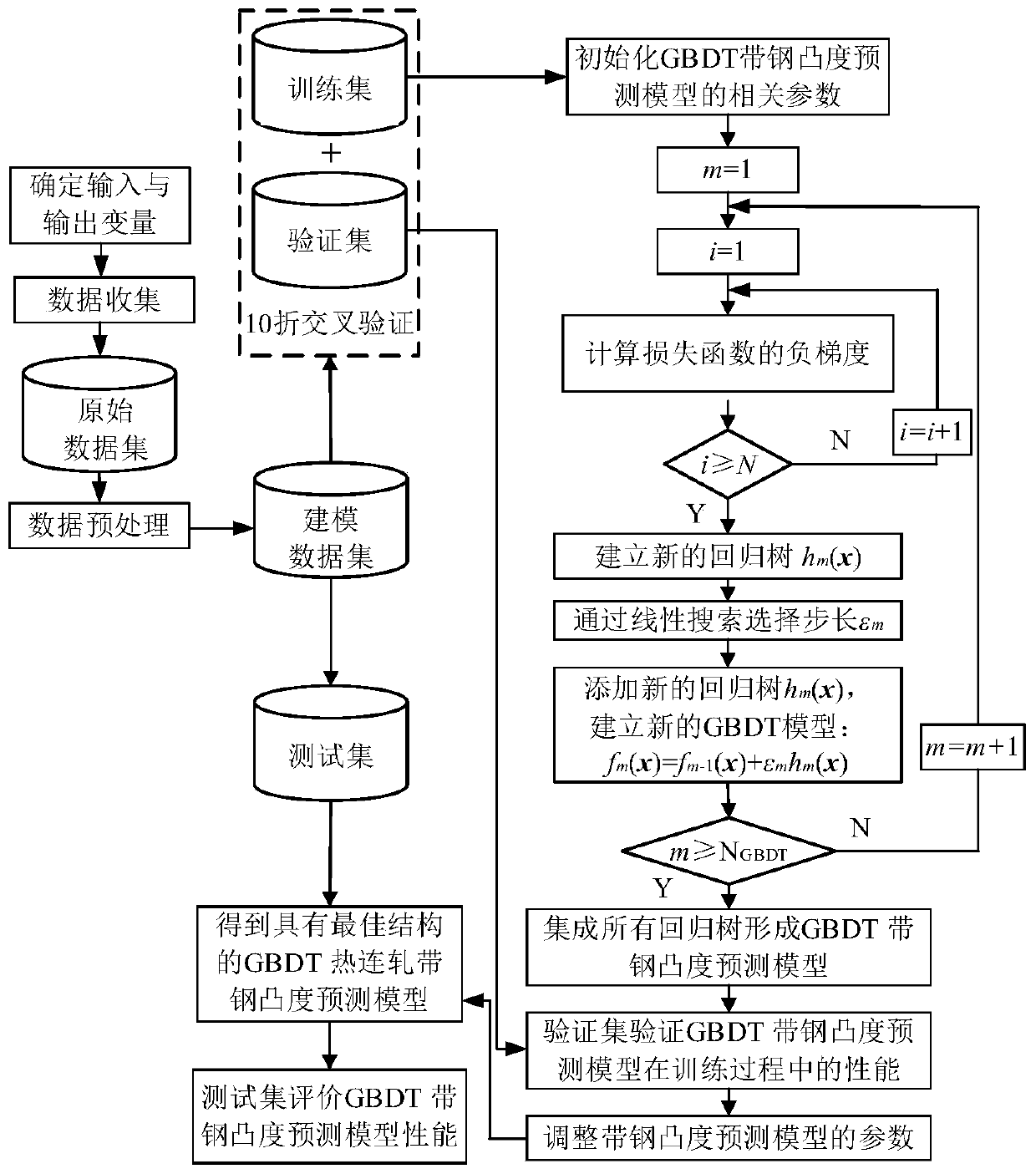

[0062] The present invention adopts the gradient boosting tree and combines a large amount of actual strip steel production data to establish a hot-rolled strip crown prediction model, and establishes the strip crown and rolling force, roll diameter, rolling mileage, rolling temperature, strip composition, etc. The relationship between process parameters that alter the actual strip crown by affecting factors such as roll deflection, roll wear, roll thermal expansion, or strip deformation.

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

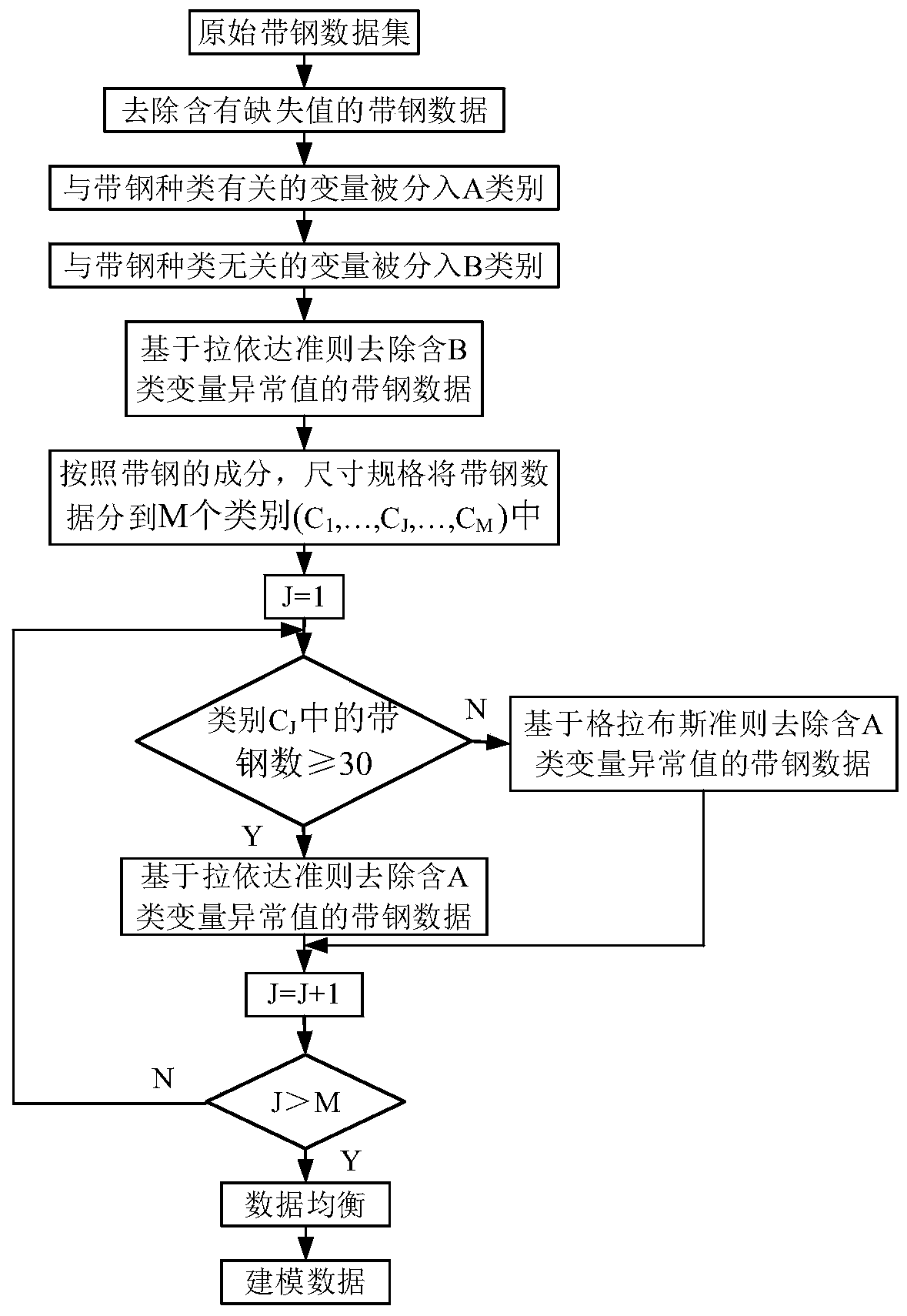

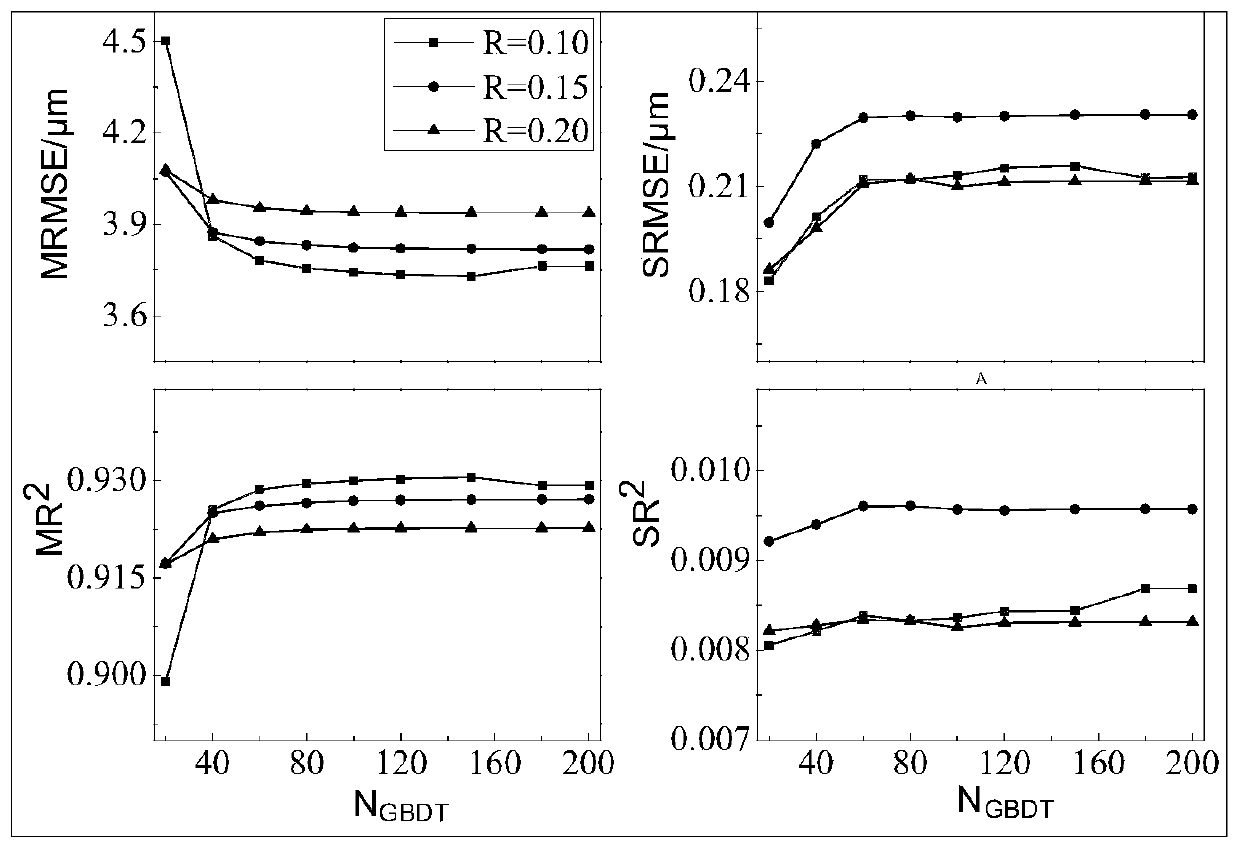

[0064] In this embodiment, the data related to the actual finishing rolling of a 1780mm strip hot rolling production line are collected to establish a hot strip crown prediction model based on the gradient boosting tree algorithm. The finishing rolling unit of the 1780mm strip steel hot rolling line is composed of seven rolling mills (F1-F7). The establish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com