Round flat cake and machine separating device on full automatic roast duck round flat cake machine

The technology of a separating device and a roasting duck cake machine is applied in the directions of baking, food oven, and baking hollow food, etc., which can solve the problems of complicated operation, long baking time, easy zooming and blistering of duck cakes, etc., so as to ensure the accuracy, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

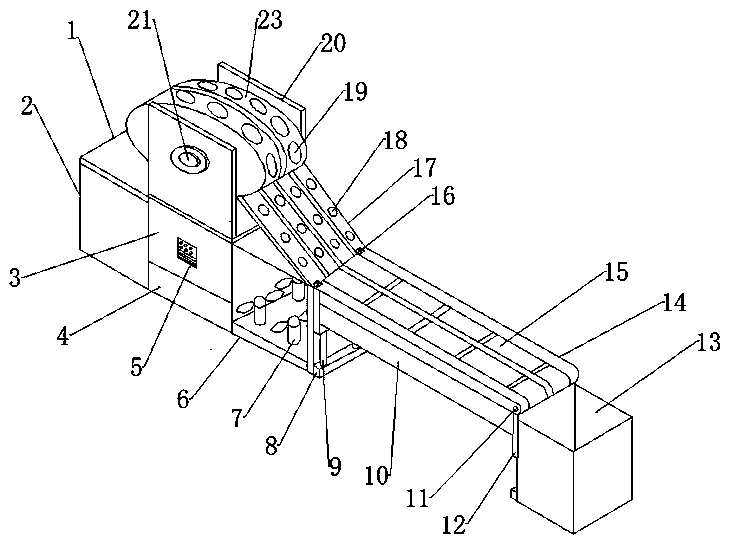

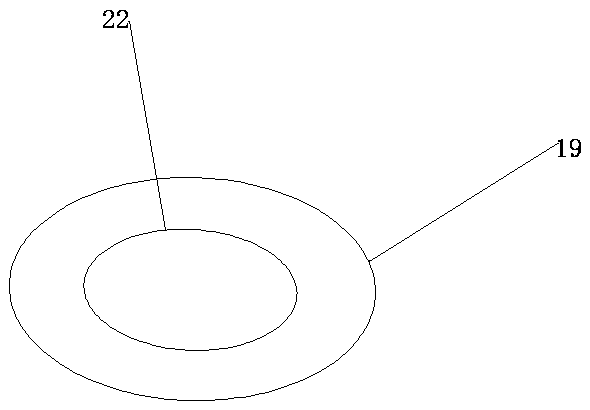

[0016] See Figure 1-2 , The present invention provides a technical solution: a cake machine separation device on a fully automatic roast duck cake machine, comprising a roast duck cake machine body 1, a motor 2, a gear box 3, a battery 4, a power control board 5, a fan base 6, and a fan 7. Conveyor belt base 8, electric telescopic rod 9, baffle 10, conveyor belt shaft 11, connecting plate 12, storage box 13, conveyor 14, conveyor belt 15, hinge 16, steel plate 17, ventilation hole 18, pancake slot 19, The supporting plate 20, the rotating shaft 21, the heating block 22 and the drum 23 are provided with a motor 2 on one side of the roast duck cake machine body 1, a battery 4 on one side of the motor 2, and a gear box 3 and a gear box 3 on the top of the battery 4 A power control board 5 is provided on the top of the gear box 3, two supporting plates 20 are provided on the top of the gear box 3, a rotating shaft 21 is provided between the supporting plates 20, a roller 23 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com