A crushing device for coal mine processing

A processing device and coal mine technology, applied in grain processing and other directions, can solve the problems of difficult crushing and insufficient crushing, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

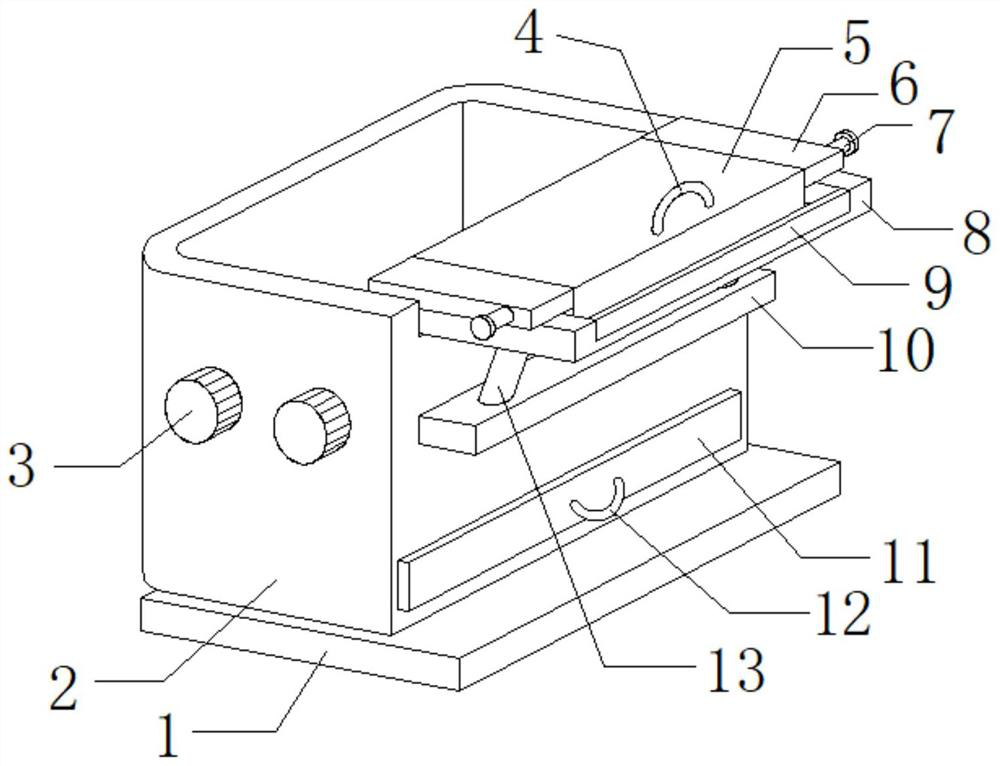

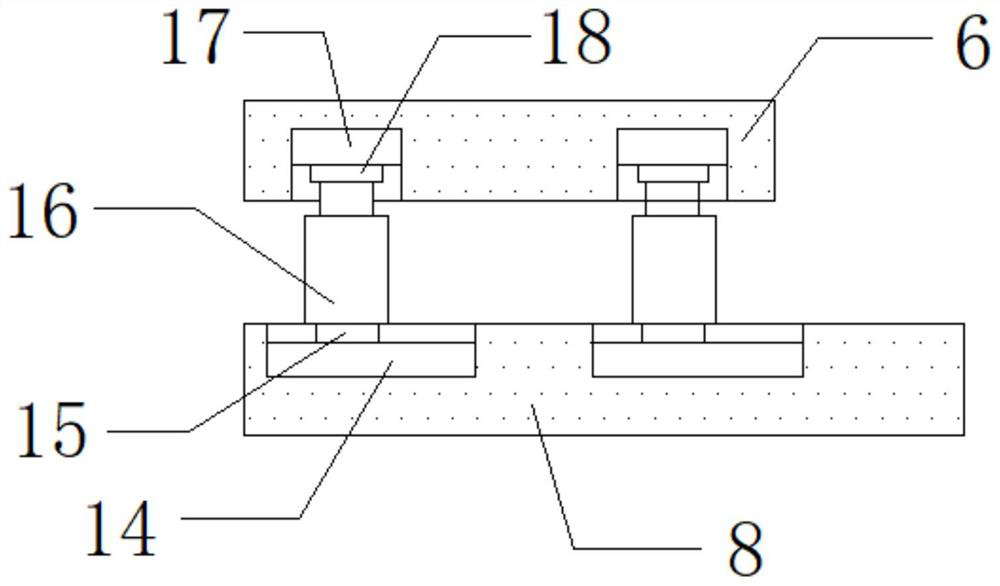

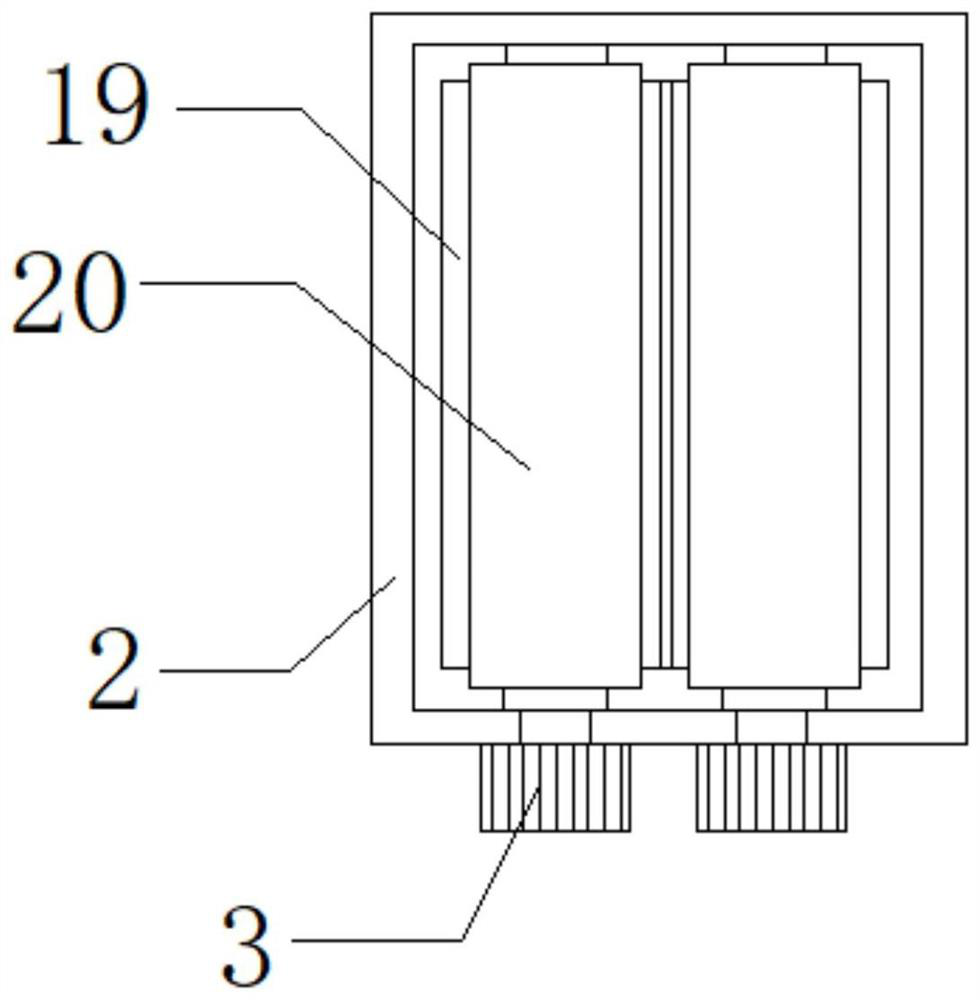

[0026] refer to Figure 1-3 , a crushing treatment device for coal mine processing, comprising a supporting shell 2, the middle outer wall of one side of the supporting shell 2 is connected with a supporting plate 10 by bolts, the outer wall of the top side of the supporting shell 2 is provided with a first groove, and The inner walls at both ends of the first groove are connected with the same support base plate 8 through the rotating shaft, and the outer walls at both ends of the top of the support plate 10 are connected with the first electric telescopic rods 13 through hinges, and the top outer walls of the two first electric telescopic rods 13 pass through respectively. The hinge is connected with the outer walls at both ends of one side of the bottom of the support base plate 8, the outer wall of the top of the support base plate 8 is provided with a crushing groove, and the four-corner outer walls of the top of the support base plate 8 are provided with second grooves, a...

Embodiment 2

[0031] refer to Figure 1-4, a crushing device for coal mine processing, which also includes springs 22 connected by bolts to the inner walls of both ends of the middle part of the supporting shell 2, and the outer walls of one side of the two springs 22 are connected by bolts to the same inclined screen 21. The outer wall on one side of the screen 21 is connected to the inner wall on the other side of the supporting shell 2 through a hinge, the outer wall on one side of the bottom of the screen 21 is connected with a vibration motor 23 by bolts, and the outer bottom wall on the other side of the supporting shell 2 is opened There is a discharge port, and the top outer wall of the discharge port is connected with a discharge cover 25 through a hinge, and a third handle is connected to one side outer wall of the discharge cover 25 through bolts.

[0032] When in use, after the two crushing processes are completed, the vibrating motor 23 is started, and the vibrating motor 23 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com