Stop-rotation type false-sending prevention and detection device for continuous die

An anti-mistake and waist-shaped technology, which is applied in the direction of forming tools, metal processing, metal processing equipment, etc., can solve the problems of abnormal detection, reduce the movable rate of stamping production, and position movement, so as to reduce the situation of anti-mistake detection and abnormal alarm , Improve the effect of production mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

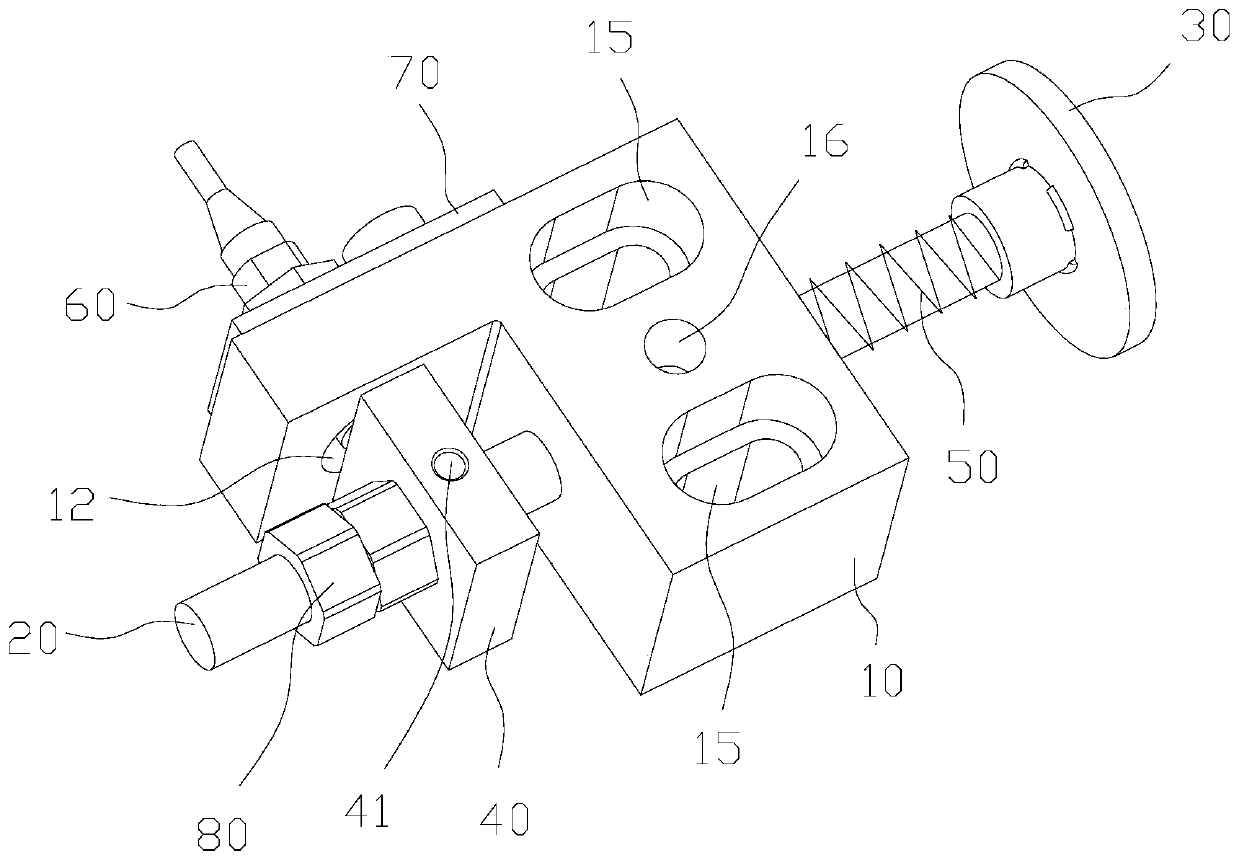

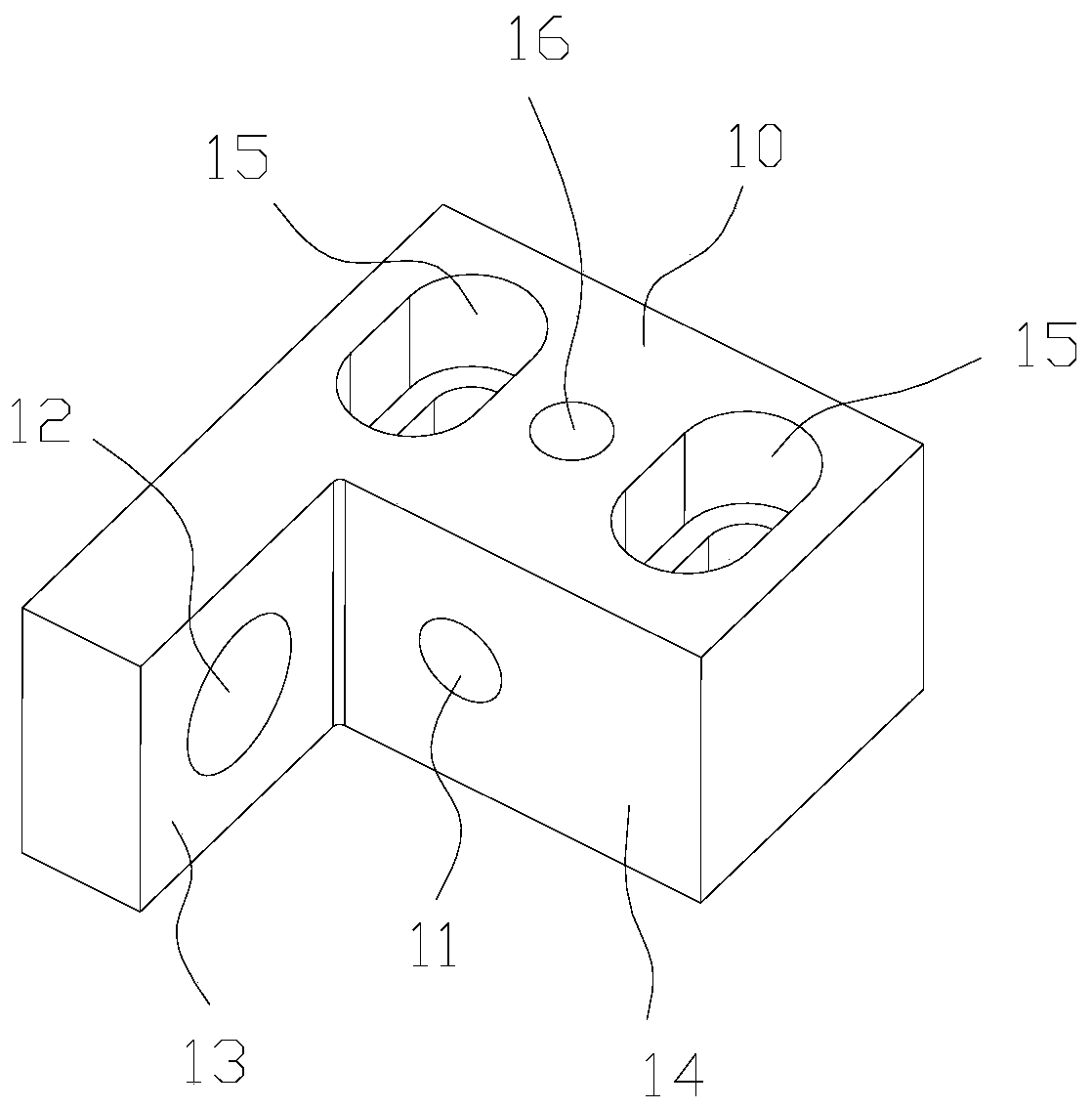

[0013] Combine below Figure 1-2 , to further describe the present invention.

[0014] A detection device for anti-mis-feeding of a continuous mold, including a fixed block 10, a sliding hole 11 and a switch through hole 12 are provided on the fixed block 10, a screw 20 is slidably and freely penetrating through the sliding hole 11, and one end of the screw 20 Fixed stopper 30, on the body of screw rod 20 fixedly sets detection block 40, detection block 40 and stopper 30 are distributed on the both sides of fixed block 10, on the shaft of screw rod 20, spring 50 is sleeved and the two ends of spring 50 are respectively against Lean on the block 30 and the fixed block 40, including the proximity switch 60, the proximity switch 60 is fixed on the outer wall of the fixed block 10 by the fixed plate 70, the proximity switch 60 passes through the switch via hole 12 so that the detection surface of the proximity switch 60 and the One of the first inner sidewalls 13 of the fixed blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com