A kind of preparation method of hydrogen-containing silicone oil

A technology of hydrogen-containing silicon and diatomaceous earth is applied in the field of preparation of hydrogen-containing silicone oil, which can solve the problems of strong irritation of post-treatment, increased technological difficulty, and a large amount of solid residues, etc. The effect of increasing interlayer spacing and lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

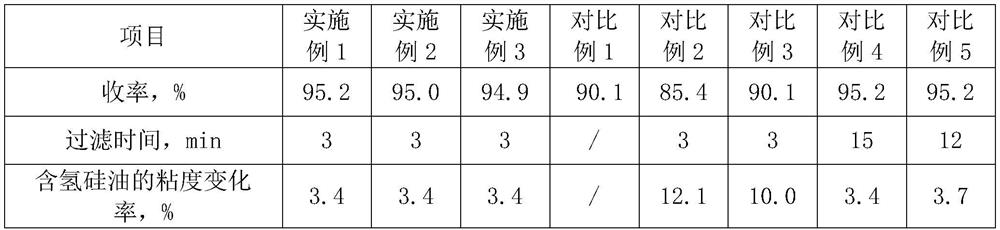

Examples

preparation example 1

[0030] Preparation Example 1 of Modified Activated Clay Catalyst: ① Take 100kg of water, add 12.5kg of phosphotungstic acid, and stir evenly to obtain a phosphotungstic acid solution; ②Add 35kg of activated clay to the phosphotungstic acid solution, Stir at a speed of 150r / min for 2 hours to obtain a suspension of activated clay; ③ decompress the suspension of activated clay to -0.09MPa and maintain it for 35min to obtain prefabricated activated clay. After washing the prefabricated activated clay with water, place it in Calcined at 165°C for 5 hours to obtain a modified and activated clay catalyst.

preparation example 2

[0031] Preparation example 2 of modified activated clay catalyst: ①Take 100kg of water, add 10kg of phosphotungstic acid, stir evenly to obtain a phosphotungstic acid solution; ②Add 30kg of activated clay to the phosphotungstic acid solution, , stirred at a speed of 100r / min for 1h to obtain an activated clay suspension; ③ after depressurizing the activated clay suspension to -0.09MPa, keep it for 30min to obtain prefabricated activated clay, wash the prefabricated activated clay with water, and place it Calcined at 160°C for 4 hours to obtain a modified and activated clay catalyst.

preparation example 3

[0032] Preparation example 3 of modified activated clay catalyst: ① Take 100kg of water, add 15kg of phosphotungstic acid, stir evenly to obtain a phosphotungstic acid solution; ② add 40kg of activated clay to the phosphotungstic acid solution, at 200r / min speed, stirring for 3h, to obtain activated clay suspension; ③ after the activated clay suspension was decompressed to -0.09MPa, maintained for 40min, to obtain prefabricated activated clay, after prefabricated activated clay was washed with water, it was placed in 170 ℃, calcined for 6 hours to obtain a modified activated clay catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com