A method for evaluating the output performance of screw drilling tools under high temperature and high pressure

A screw drilling tool, high temperature and high pressure technology, applied in the field of drilling engineering technology and petroleum drilling engineering, can solve the problem of difficulty in actual evaluation of output performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

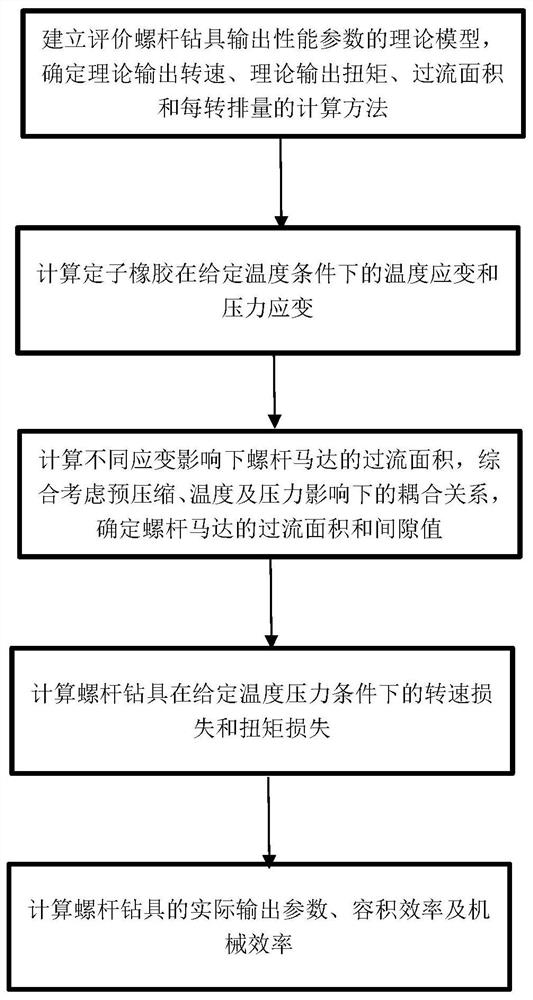

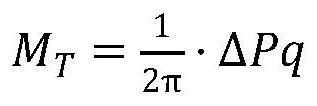

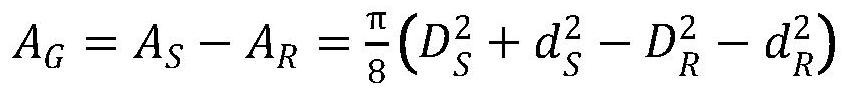

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0059] Next, an example calculation is performed in conjunction with a domestic brand of multi-head screw drilling tools. The structural parameters of the screw motor are shown in Table 1.

[0060] Table 1 Screw Motor Parameters

[0061]

[0062] The plastic viscosity of the drilling fluid is 15mPa·s, the friction coefficient between the rotor and the stator of the screw motor is 0.1, the material of the rotor of the screw motor is 45# steel, the density is 7850kg / m3, the Poisson’s ratio is 0.25, and the modulus of elasticity is 206000MPa. It is nitrile rubber with Shore hardness of 80, Poisson's ratio is 0.49, elastic modulus is 10.98MPa, and linear expansion coefficient is 196×10 -6 .

[0063] Assuming that the well depth of a given screw drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com