Terminal group and forming method thereof

A forming method and technology of terminal group, applied in contact parts, circuit/collector parts, welding/welding connection, etc., can solve the problems affecting the overall appearance of the terminal group's electrical conductivity, serious burns, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

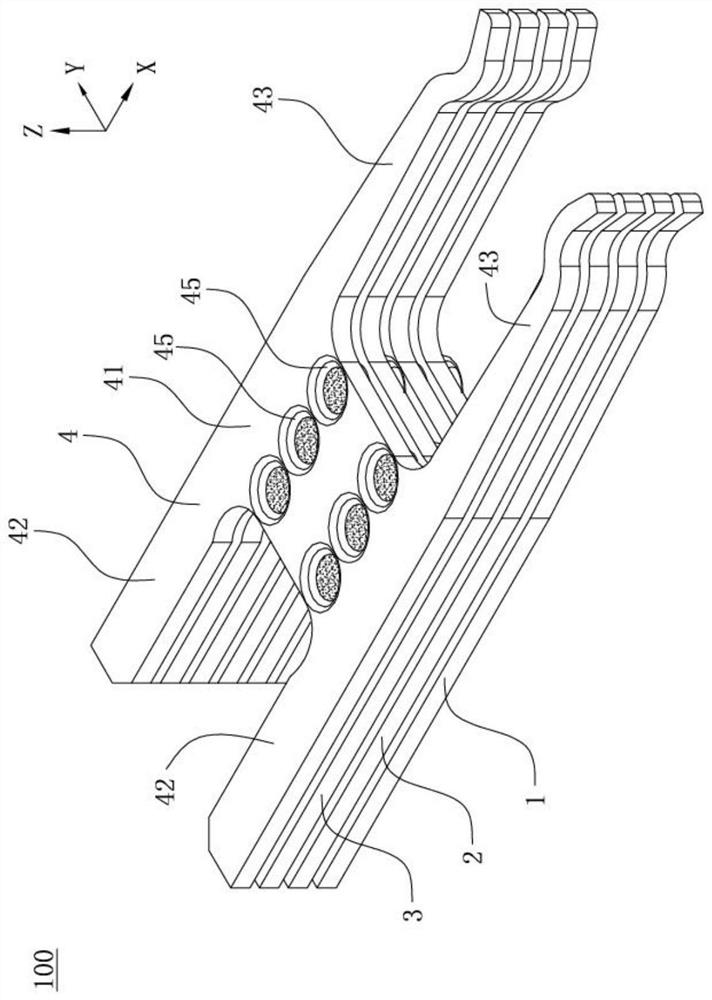

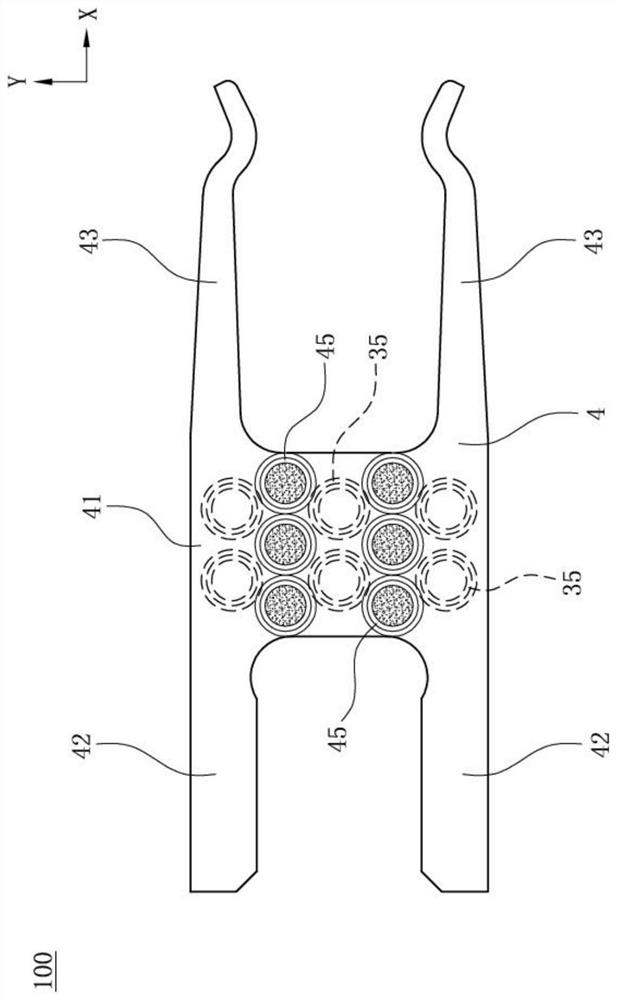

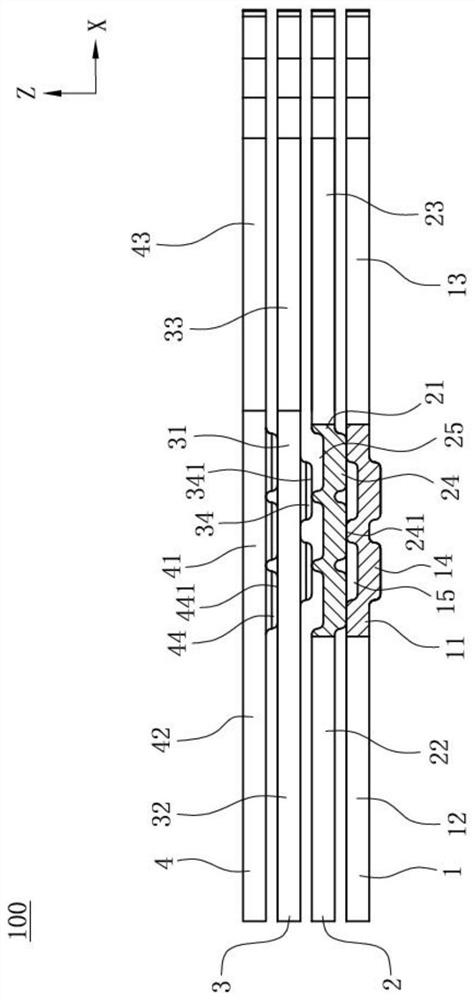

[0047] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

[0048] The present invention defines the X-axis direction as the front-rear direction, the Y-axis direction as the left-right direction, and the Z-axis direction as the up-down direction.

[0049] Such as figure 1 , Figure 4 and Figure 5 Shown is a terminal set 100 of the present invention, which electrically connects a lead piece 200 to a connecting piece 300 for transmitting large current. In this embodiment, the lead member 200 is a copper plate and is electrically connected to the rear end of the terminal group 100, and the rear end of the lead member 200 is also electrically connected to a cable (not shown in the figure). ), the docking member 300 is an electronic card and is electrically connected to the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com