Shelf, bearing disc, tray, buffer cavity, loading cavity and substrate conveying system

A transmission system and buffer cavity technology, applied in gaseous chemical plating, crystal growth, coating and other directions, can solve the problem of inconvenient pick and place, and achieve the effect of speeding up the production tact, speeding up the rhythm of the transmission, and saving the transmission time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

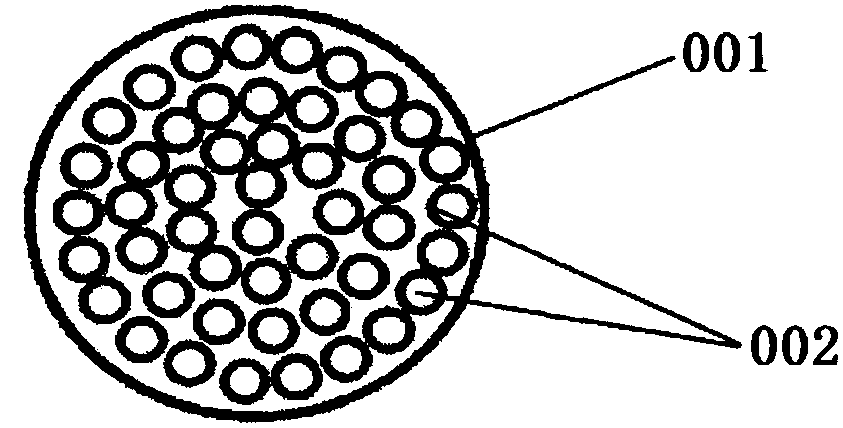

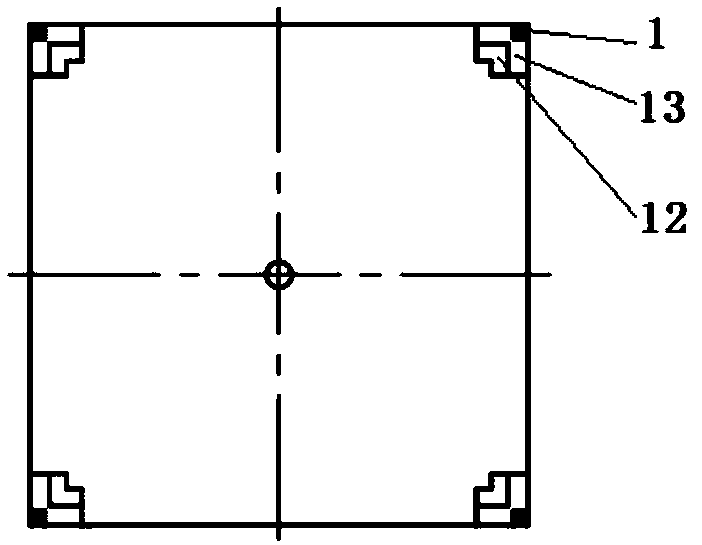

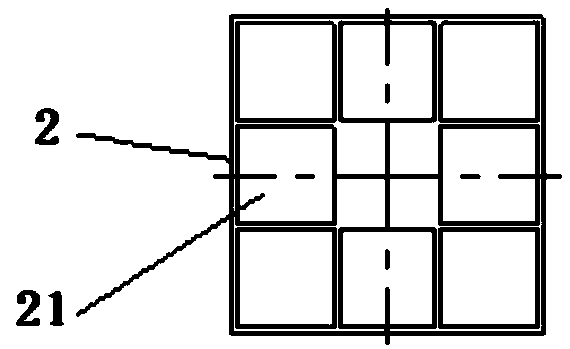

[0051]One aspect of the present application provides a shelf, including a bracket and a driving device, and the bracket includes N mutually parallel support columns 1 and two connecting plates. Both ends of the N parallel support columns 1 are respectively connected by connecting plates to form an accommodating space with an N-sided cross-section, where N is a positive integer greater than or equal to 3. The bracket also includes at least one set of support structures, each set of support structures is used to carry a disc. The driving device is in drive connection with the connecting plate, and the driving device is used to drive the bracket to rotate.

[0052] Therefore, the discs can be taken and placed at will by rotating the N sides of the whole shelf, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com