Prefabricated assembly type open caisson

A prefabricated assembly and caisson technology, applied in caissons, water conservancy projects, artificial islands, etc., can solve problems such as leakage and weakened structural integrity of prefabricated caissons, and achieve the effect of good integrity and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and the following embodiments.

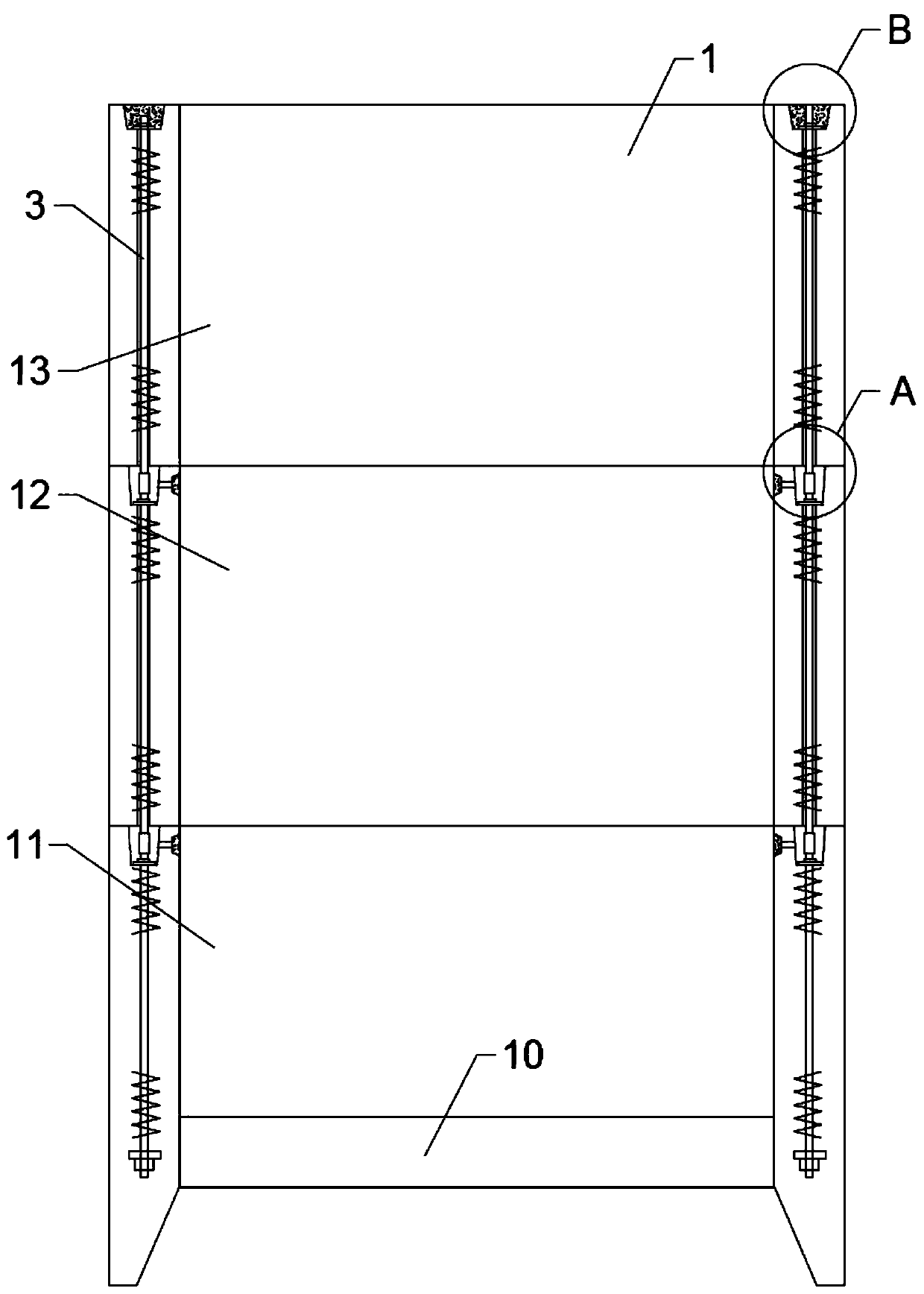

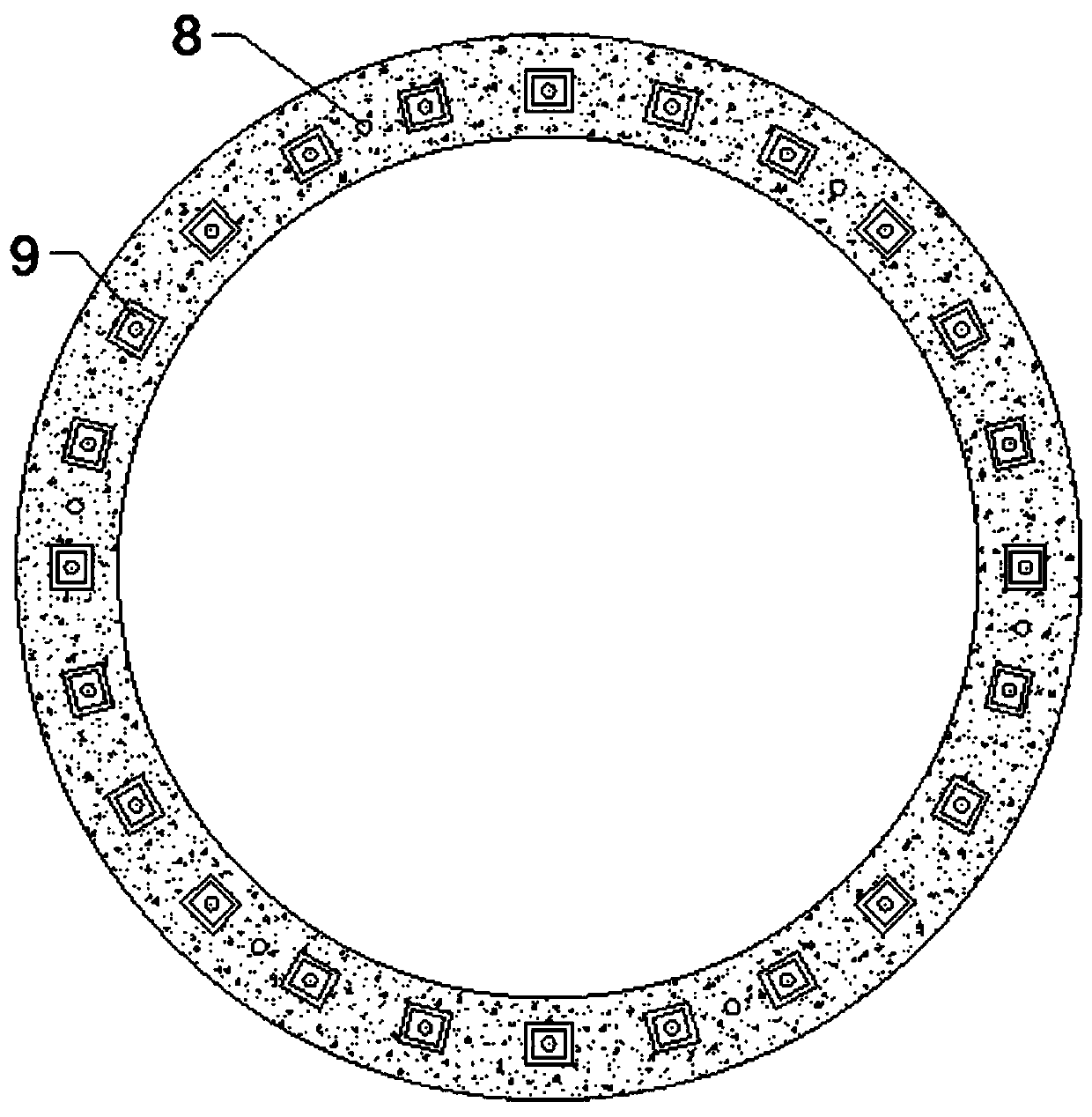

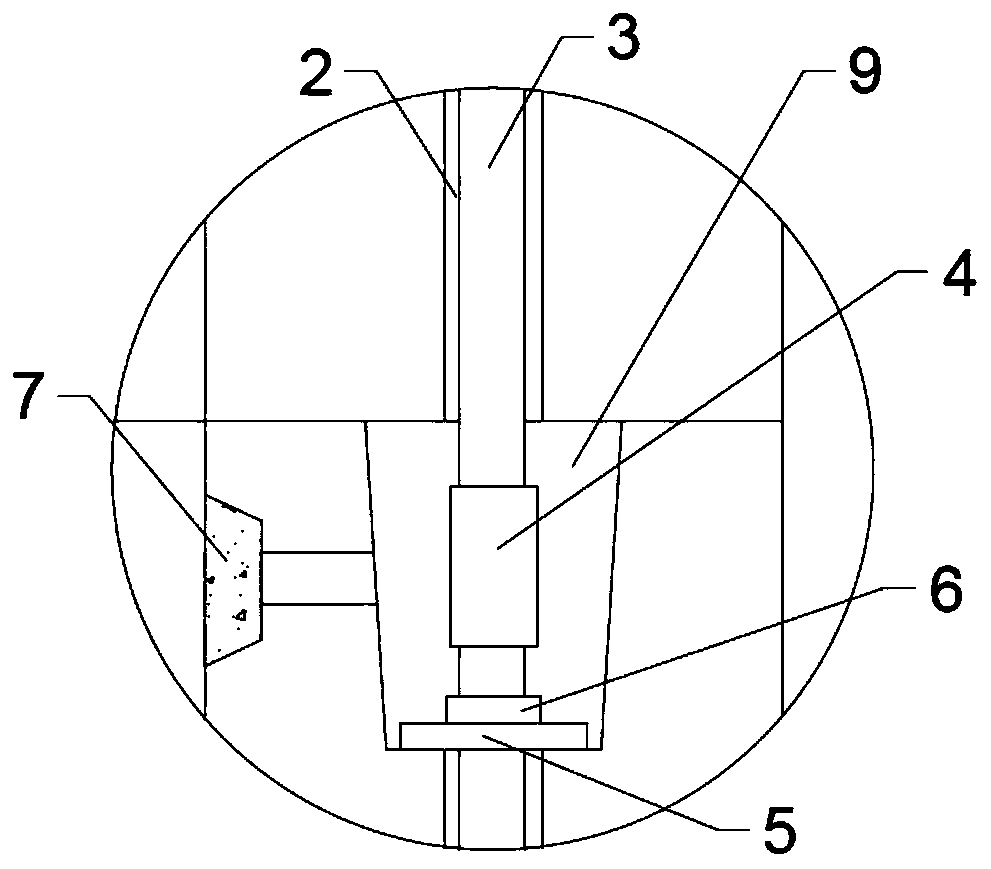

[0022] The first aspect of the embodiments of the present invention provides a construction method for a prefabricated caisson, such as Figure 1-Figure 6 As shown, the caisson is spliced by a plurality of sections 1, and the section 1 is divided into a bottom section 11, a middle section 12 and an upper section 13, and the middle section 12 and the upper section 13 are provided with grouting The hole 7 is vertically provided with a plurality of metal bellows penetrating along the middle section 12 and the upper section 13, and a penetrating steel rod channel 2 is formed in the metal bellows. The construction method includes the following steps:

[0023] Step 1, caisson design, precast segment 1;

[0024] Among them, caisson design includes: calculating the length of caisson and each section and the design elevation of caisson according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com