a plug valve

A plug valve and valve body technology, applied in the field of plug valves, can solve the problems of poor safety, easy aging of sealing structure, and inability to adjust the main fire and secondary fire at the same time, so as to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

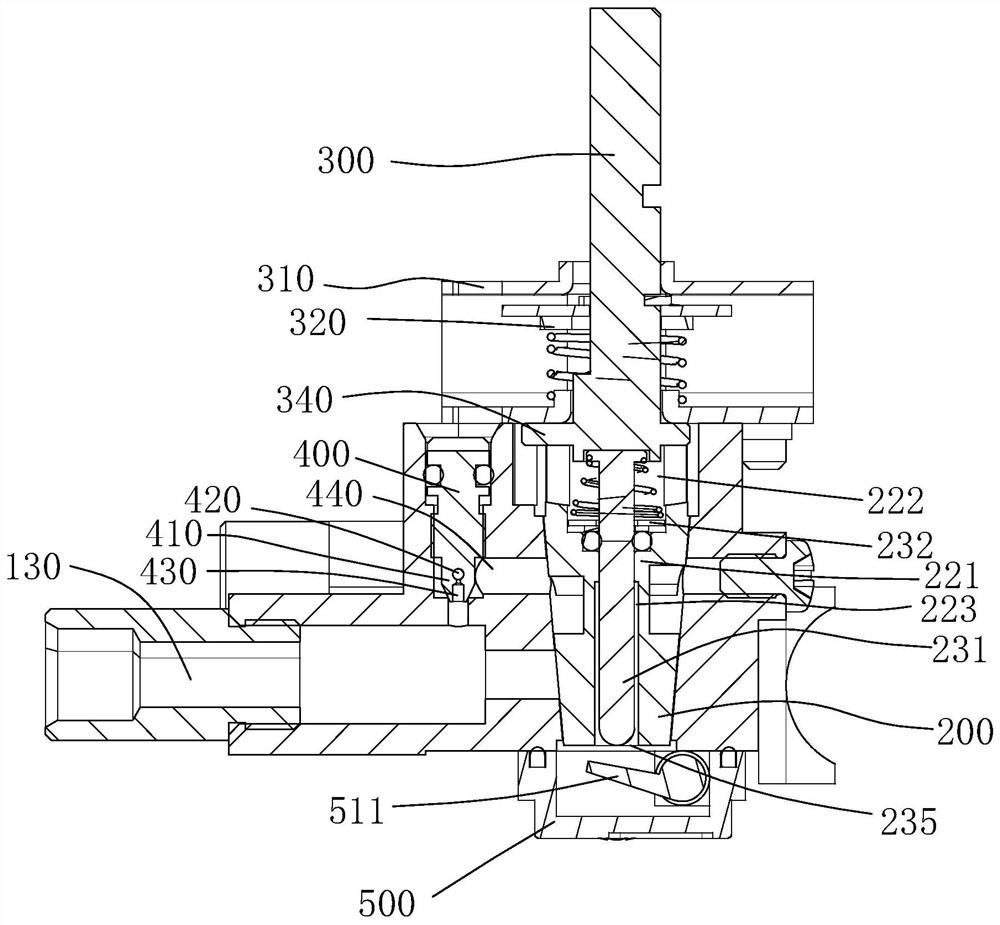

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Combine below Figure 1 to Figure 11 The technical solution provided by the present invention is described in more detail.

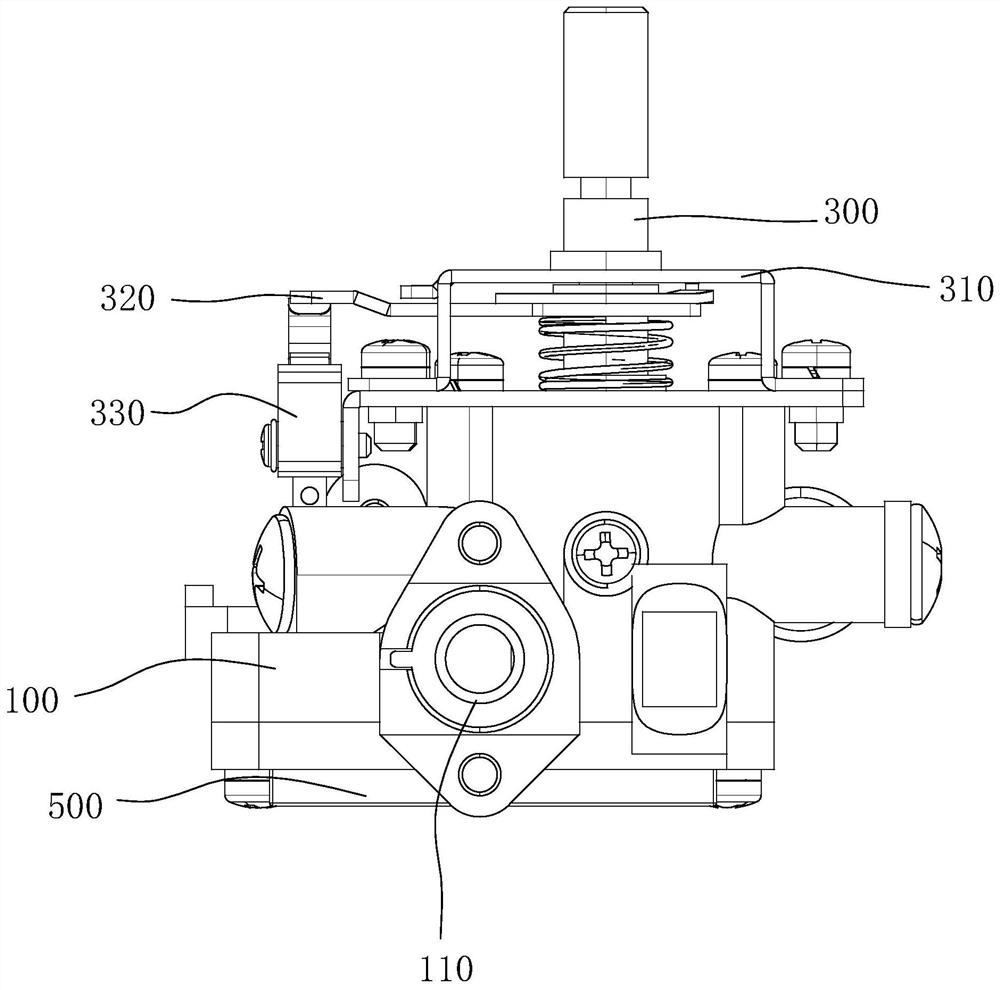

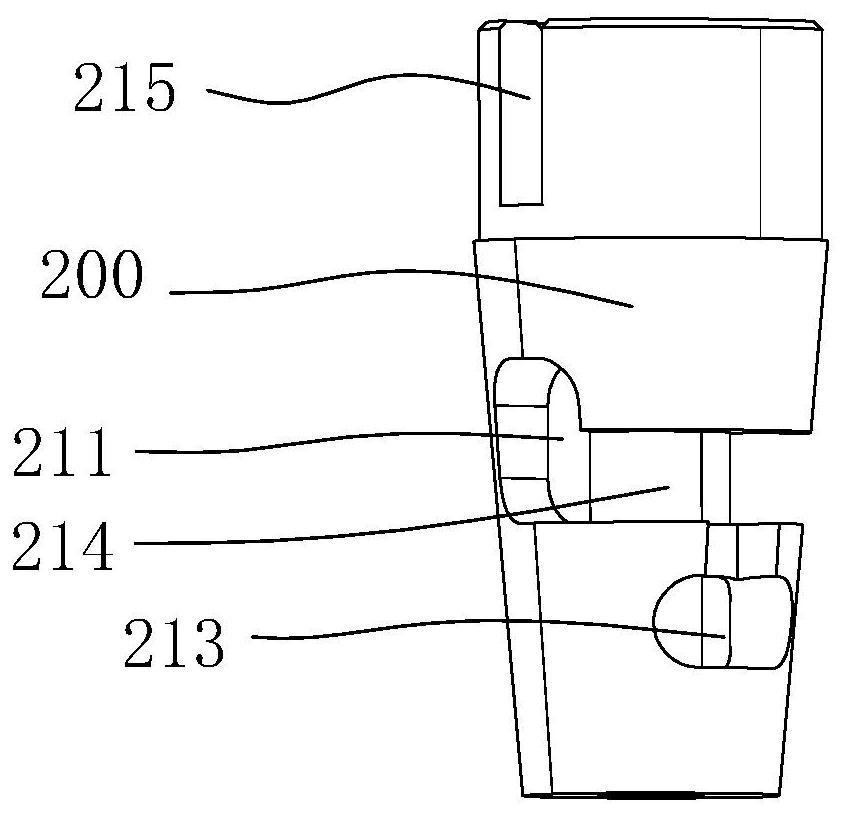

[0034] A plug valve, such as Figure 1-Figure 11 As shown, it includes: a valve body 100 , a valve core 200 , a solenoid valve 233 , a knob rod 300 , a flow regulating nail 400 , and a bottom cover 500 .

[0035] The valve body 100 is provided with an intake channel 110 , a main fire channel 120 and a secondary fire channel 130 . Specifically, the main fire passage 120 and the secondary fire passage 130 are arranged in parallel on the same side of the valve body 100 , and the intake passage 110 is arranged on the other side of the valve body 100 . In this embodiment, the air intake passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com