Double-vibration forest fruit picking trolley

A dual-vibration and main-vibration technology is applied to harvesting machines, chassis of agricultural machinery, agricultural machinery and machinery, etc. It can solve the problems of labor shortage, influence of fruit collection, and high labor intensity, so as to ensure positioning reliability, picking and The effect of convenient collection and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

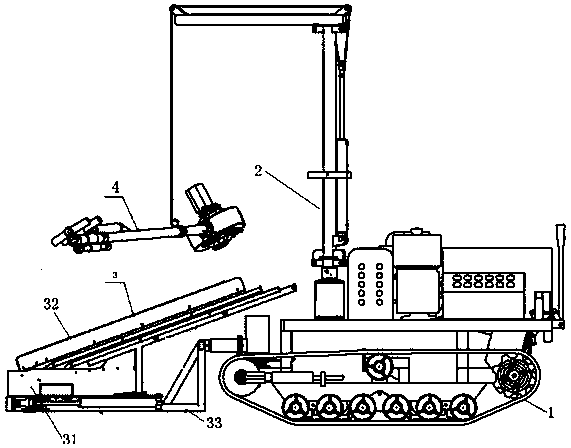

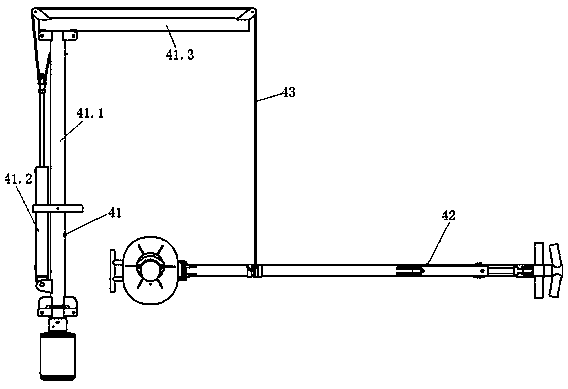

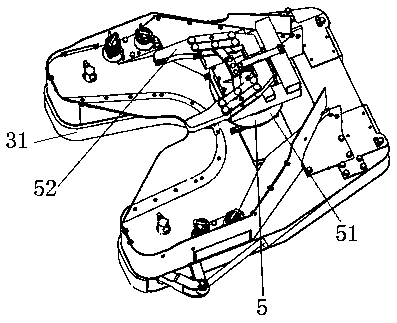

[0040] Combine below Figure 1 to Figure 11 Embodiments of the present invention are described in detail.

[0041] The dual-vibration forest fruit picking vehicle is characterized in that it includes a crawler-type running mechanism 1, a vibration mechanism 2 that clamps the trunk to vibrate the fruit, and a receiving mechanism 3 for catching the vibrated fruit. The receiving mechanism 3 is installed on the The front end of the running mechanism 1 can be opened or folded in an umbrella shape on the outer periphery of the trunk. The vibrating mechanism 2 includes the auxiliary vibrating element 4 suspended directly above the receiving mechanism 3 and the main vibrating element 5 mounted on the receiving mechanism 3. The main vibrating element 5 is located below the auxiliary vibrating element 4, the main vibrating element 5 and the auxiliary vibrating element 4 respectively clamp the tree trunk and transmit vibrations, and the clamping positions of the main vibrating element 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com