A kind of manipulator terminal device and its picking method for stringing tomatoes

A technology of terminal device and manipulator, which is applied to manipulators, harvesters, agricultural machinery and implements, etc., can solve the problems of complex overall structure and control, poor capture performance of fruit stems, and fruit stems escaping outwards, so as to reduce weight and structure. Small size, reduced power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments. Unless otherwise specified, the materials and installations used in the present invention are conventional materials and installation methods in the technical field.

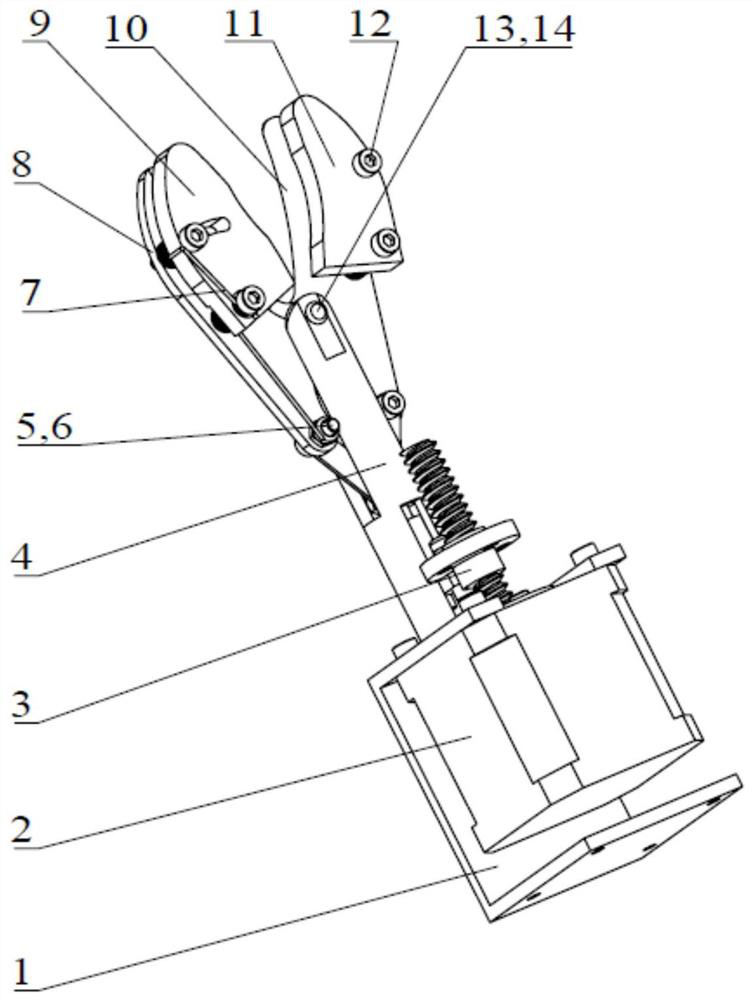

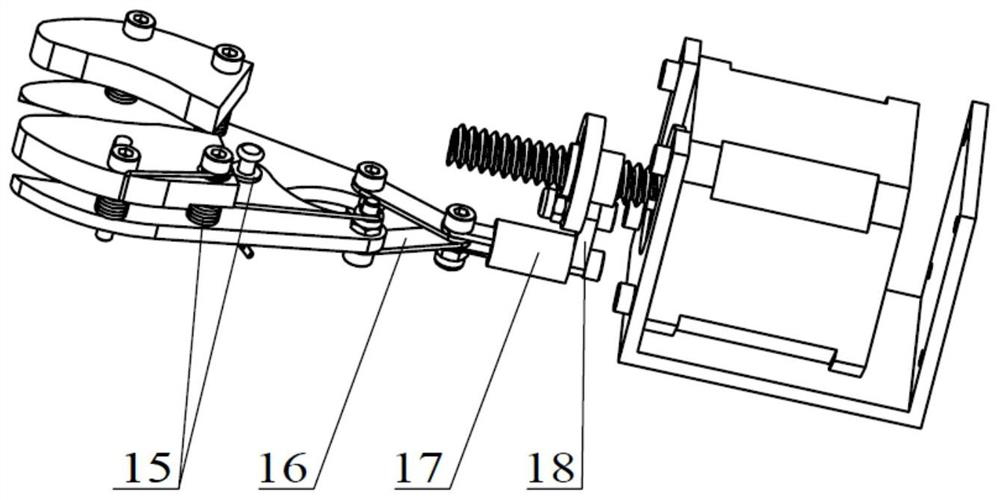

[0035] Such as figure 1 with figure 2 Shown, a kind of manipulator terminal device of tomato bunching, comprises clamping-shearing mechanism, driving mechanism and connecting rod, and described clamping-shearing mechanism is installed in front of driving mechanism;

[0036] The clamping-shearing mechanism includes a clamping part and a shearing part, and the clamping part is installed on the upper surface of the shearing part;

[0037] Such as figure 1 with figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com