Self-cleaning device for horizontal milling machine

A self-cleaning, milling machine technology, applied in the field of milling machines, can solve the problems of reducing the service life of milling machines and difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

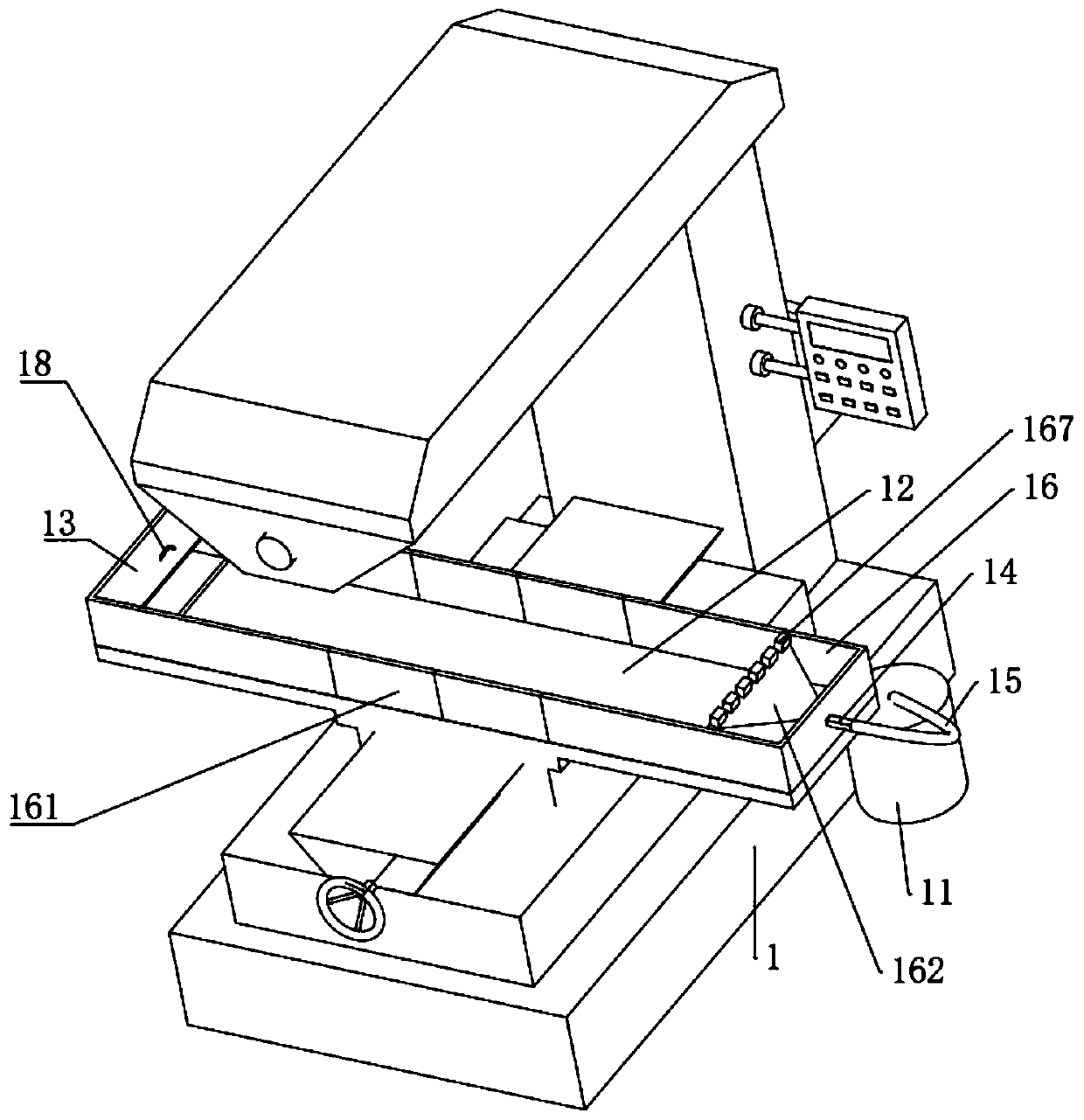

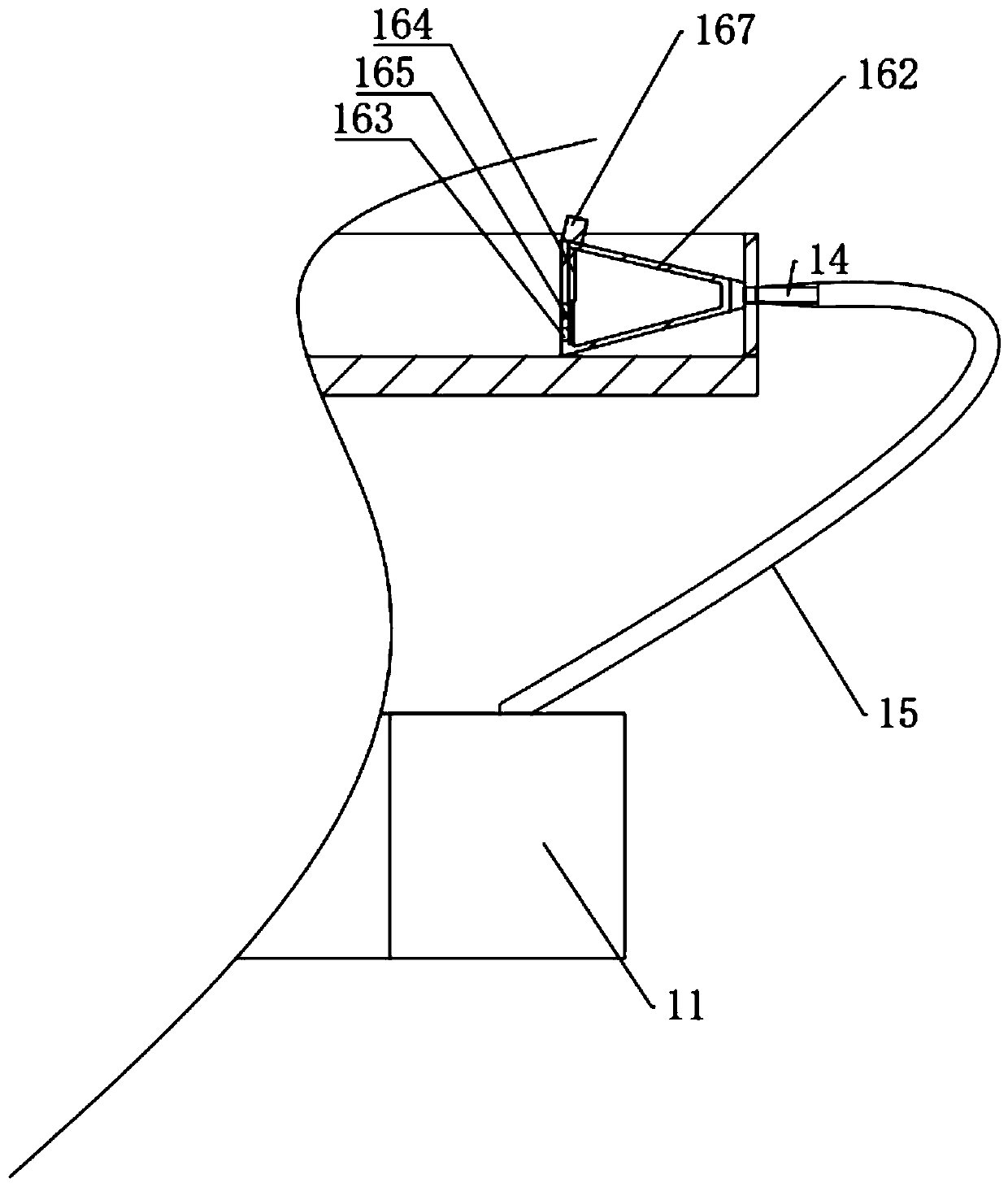

[0027] Embodiment 1: a kind of self-cleaning device of horizontal milling machine, as figure 1 with figure 2 , including an air pump 11 arranged on the right side of the host base 1, a workbench 12 is arranged above the host base 1, a waste collection box 13 is arranged at one end of the workbench 12, and an automatic dust removal nozzle 14 is arranged at the other end, the automatic dust removal nozzle 14 and the air pump 11 are connected with a connecting hose 15, and both sides of the workbench 12 are provided with a U-shaped protective plate 16, and the two protective plates 16 are provided with an extension plate 161 extending toward each other on the opposite side. Two opposite extension plates 161 interfere with each other, and the extension plate 161 and the protective plate 16 are slidably connected, so that the extension plate 161 can be slid into the protective plate 16, thereby facilitating the user to take the protective plate 16, and the nozzle 14 is arranged on...

Embodiment 2

[0036] Embodiment 2: a horizontal milling machine, including the above embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com