A three-phase asynchronous motor

A three-phase asynchronous, body-based technology, applied in the direction of asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of poor heat dissipation of motors and reduced wind power of fans, etc., and achieve the advantages of easy to maintain non-rotation, reduce impact, and reduce accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-3 The application is described in further detail.

[0035] The embodiment of the present application discloses a three-phase asynchronous motor.

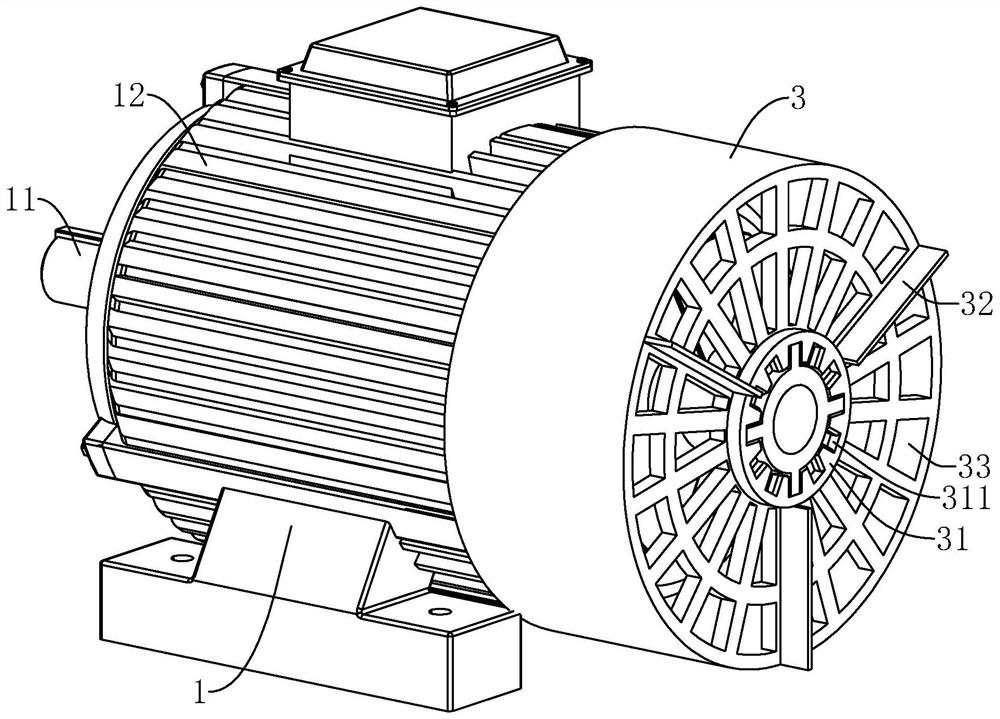

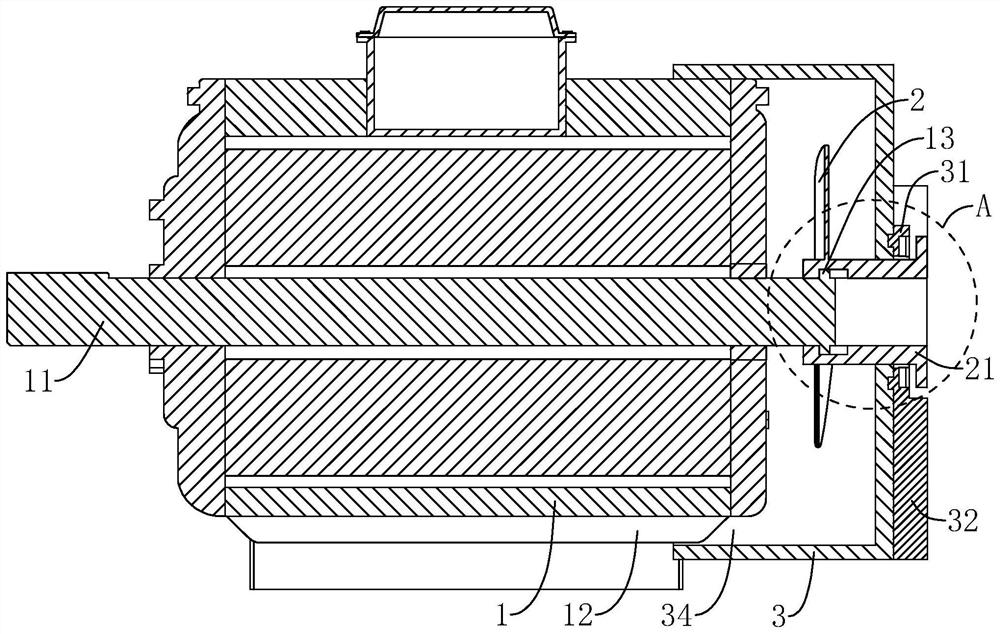

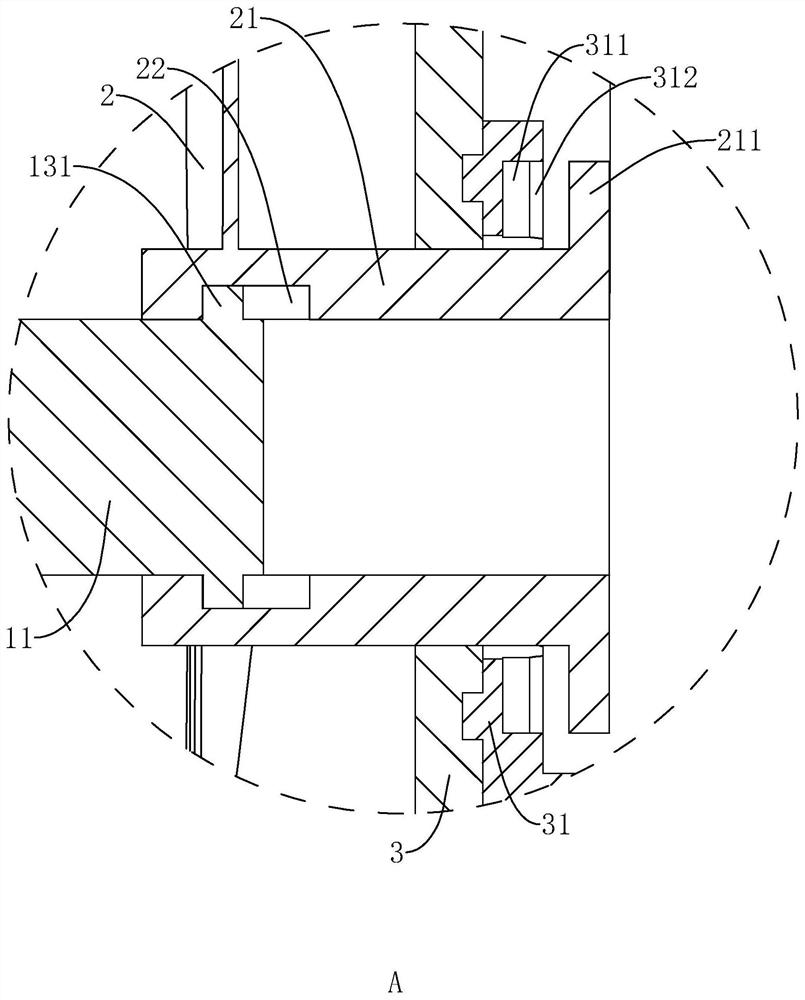

[0036] refer to figure 1 , the three-phase asynchronous motor includes a body 1, a rotating shaft 11 rotatably connected to the body 1, an end cover 3 fixedly connected to one end of the body 1, a number of cooling ribs 12 are fixedly connected to the circumferential side wall of the body 1, and one end of the rotating shaft 11 extends to the end cap 3 and rotate in the end cap 3.

[0037] refer tofigure 1 A sleeve 31 is rotatably connected to the end face of the end cover 3 facing away from the body 1 , and the sleeve 31 is located at the center of the end cover 3 . A plurality of air inlets 33 are opened on the end surface of the end cover 3 along the circumferential direction of the sleeve 31 , and the air inlets 33 are evenly distributed along the circumferential direction of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com