Hardware defect identification method, system and storage medium

A technology for defect identification and hardware, applied in the control of workpiece feed movement, metal processing equipment, grinding machine parts, etc., can solve problems such as limited precision, easy to be boring, fatigue, etc., to reduce errors and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

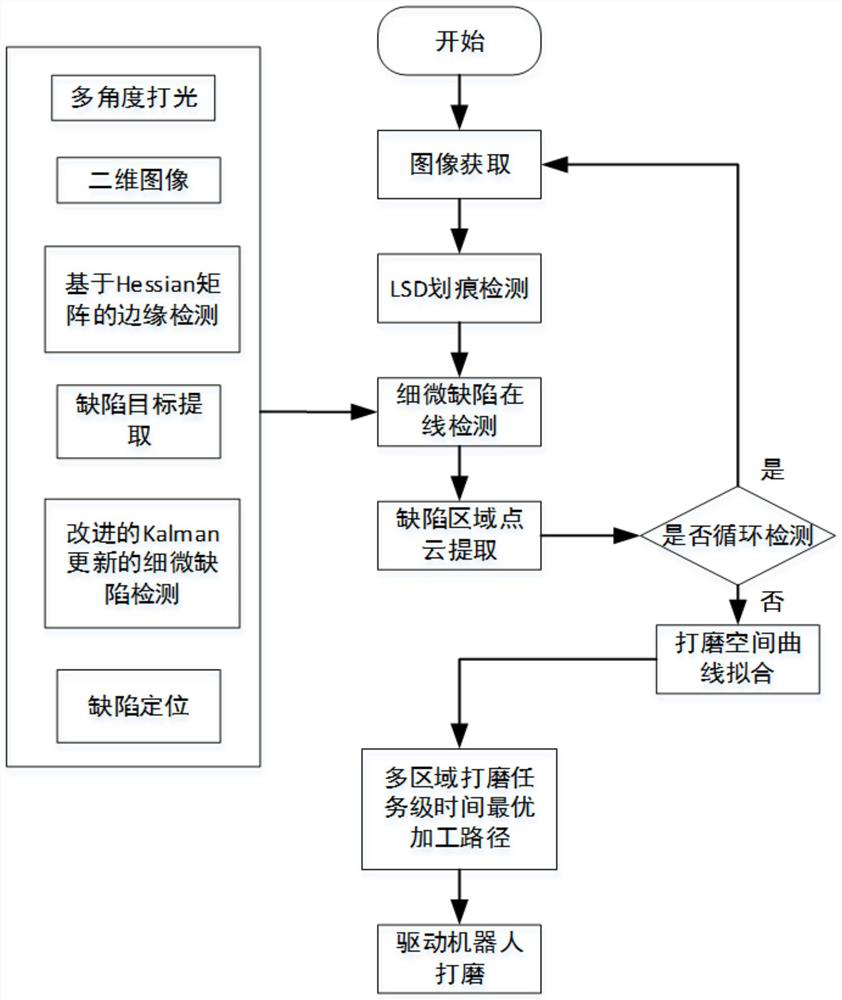

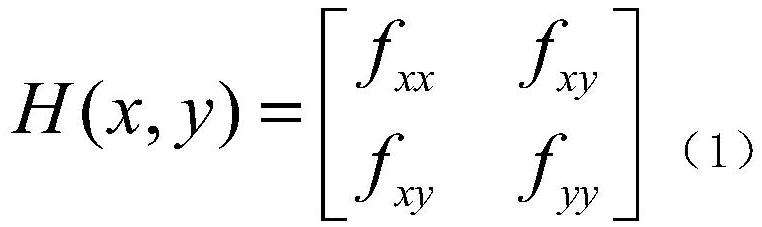

[0054]The present invention is further explained and explained in conjunction with the accompanying drawings and specific embodiments. For the step number in the embodiment of the present invention, it is only provided for convenience of explaining that the order between the steps does not limit any defined, and the order in which the steps in the embodiment can be performed according to the understanding of those skilled in the art. Adaptability adjustment.

[0055]The operation object of the present invention is the defects generated by various hardware parts in the processing process.

[0056]The object of the present invention is characterized in that metal defects are mainly formed in metal molding and post-processing, and the main defect type has metal scratches, uneven pits, and fine stain, and human detection is high, high leak detection rate, and poor product quality stability .

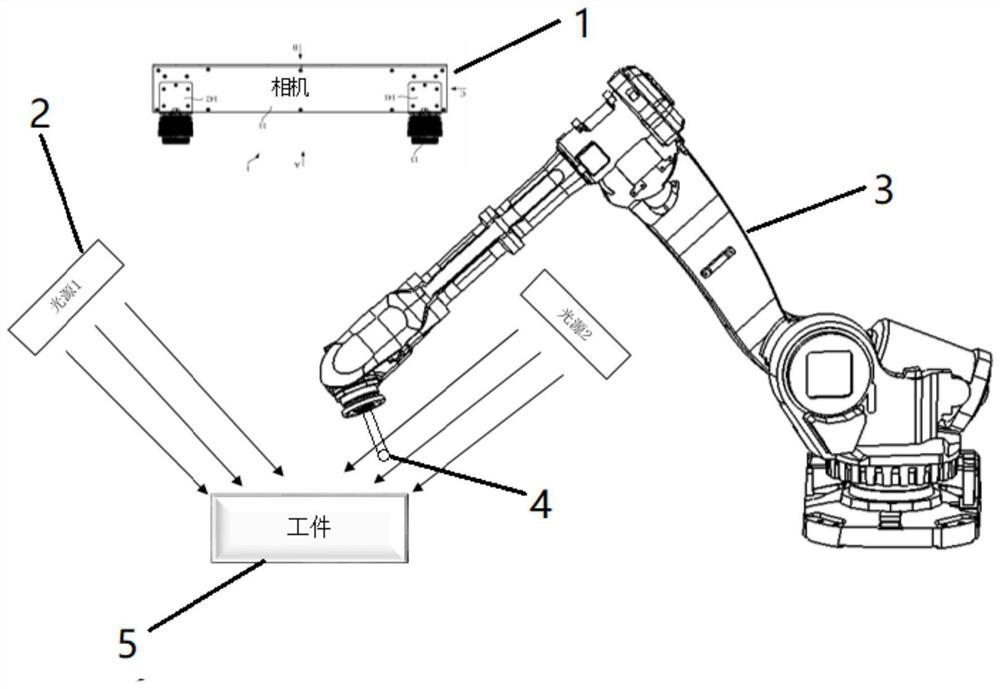

[0057]Here, embodiments of the present invention provide a system apparatus corresponding to a five-gol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com