Contact method wheel radial run-out detection system and method

A detection system and contact method technology, applied in the field of rail transit, can solve the problems of detection mechanism detection accuracy and structural stability to be further improved, mechanism impact damage, and the height of the scratch rod cannot be controlled, so as to achieve structural stability improvement and extension Effect of service life and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

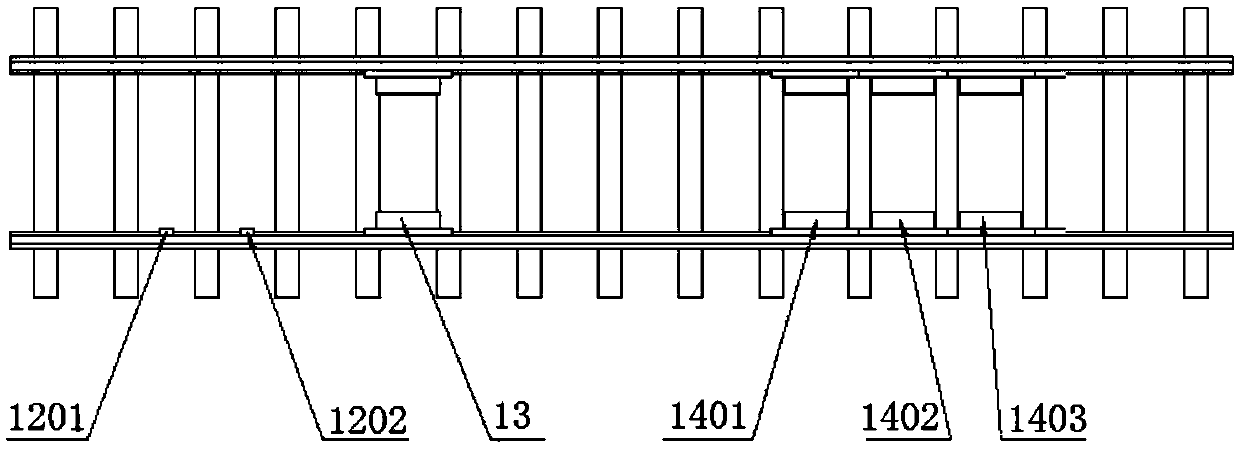

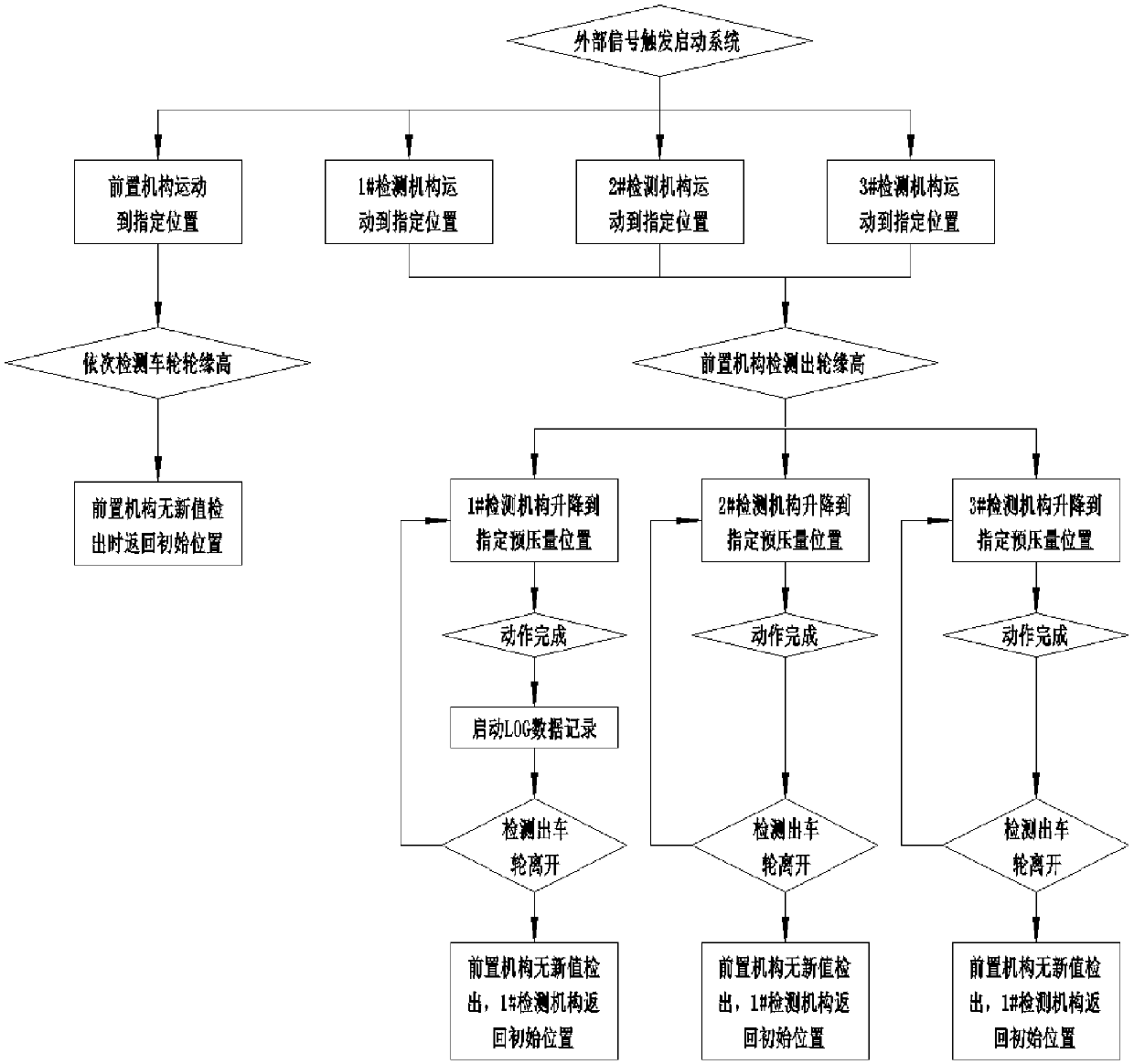

[0061] combine figure 1 , a contact method wheel runout detection system of the present embodiment includes a front mechanism 13 and a detection mechanism installed sequentially on the inner side of the track along the direction of train storage, wherein the front mechanism 13 is used to measure the rim height of the wheel to be detected. Detection, the detection mechanism is used to detect the radial runout of the wheel. Both the detection mechanism and the front-end mechanism 13 are connected to the control system, and the start and stop of the front-end mechanism 13 and the detection mechanism are controlled by the control system.

[0062] In this embodiment, a front-end mechanism is added in front of the detection mechanism (the direction of the train entering the warehouse), and the rim height of the wheel to be detected is measured by the front-end mechanism 13, and according to the measured rim height and the current position of the detection mechanism, through The con...

Embodiment 2

[0070] The structure of the contact method wheel runout detection system in this embodiment is basically the same as in Embodiment 1, the main difference is that the detection mechanism in this embodiment is symmetrically installed on the inner side of the double-sided track, and the number of detection mechanisms on the same side is ≥ 2 , and the sum of the lengths of the detection mechanisms on each side is greater than the circumference of the wheel, so that it can not only ensure the detection of the circumferential data of the wheel tread that is greater than the circumference of the wheel, but also meet the requirements for the detection of different front and rear wheels, and prevent the previous wheel from failing. The impact of leaving the detection mechanism and the next wheel entering the detection mechanism on the detection result. Wherein, the first detection mechanism maintains a certain distance from the front mechanism 13, and the time taken by the wheel to trav...

Embodiment 3

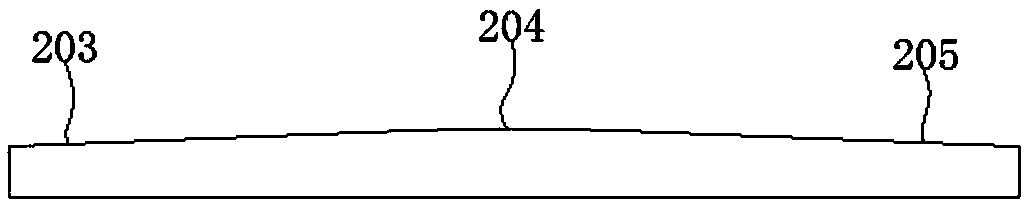

[0073] A contact method wheel runout detection system of this embodiment is basically the same in structure as Embodiment 2, the main difference is that this embodiment also includes a base plate assembly 5, which is fixedly installed under the track 1, and fixed The plate assembly 4 , the lifting drive mechanism 6 and the guide post guide sleeve mechanism 11 are all fixedly installed on the base plate assembly 5 . Such as Figure 14 As shown, the guide post guide sleeve mechanism 11 of this embodiment includes a base 1101, a guide sleeve 1102 and a guide post 1104, wherein the base 1101 is fixedly installed on the bottom plate assembly 5, and the guide sleeve 1102 is fixedly installed on the upper part of the first sliding plate 301 , the bottom of the guide post 1104 is fixedly installed on the base 1101, and its upper part passes through the guide sleeve 1102, and an inner liner 1103 is provided between the guide sleeve 1102 and the guide post 1104, and the inner liner 1103...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap