Refining method of thiothiamine and the obtained thiothiamine product and vitamin B1 product

A technology of thiothiamine and refining method, which is applied in the field of thiothiamine products and vitamin B1 products, and can solve the problems of vitamin B1 product rework, vitamin B1 production cost increase, vitamin B1 chromatographic purity and other detection indicators unqualified, etc. problems, to achieve the effect of increased purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

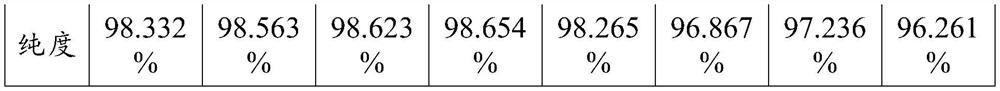

Embodiment 1

[0082] A refined method for thiothiamine, said method comprising the following steps:

[0083] (1), first wash the crude thiothiamine with ethanol at 15° C. to remove impurities soluble in ethanol in the crude thiothiamine, then filter and dry to obtain the crude thiothiamine after alcohol washing ;

[0084] The ratio of the thiothiamine crude product to ethanol is 1:2.

[0085] The drying time after the alcohol washing is 2 hours, and the temperature is 40°C;

[0086] (2) The crude thiothiamine washed with alcohol and dried was washed with distilled water at 15° C. to remove impurities dissolved in water in the thiothiamine to obtain crude product A;

[0087] The ratio of the crude thiothiamine to distilled water is 1:2.

[0088] The drying time after washing with water is 5 hours, and the temperature is 60°C;

[0089] (3) Mix the crude product A and ethanol at a ratio of 1:40, then reflux and heat up to 70°C until the crude product A is completely dissolved to obtain sol...

Embodiment 2

[0094] A refined method for thiothiamine, said method comprising the following steps:

[0095] (1), first wash the crude thiothiamine with ethanol at 25° C. to remove impurities soluble in ethanol in the crude thiothiamine, then filter and dry to obtain the crude thiothiamine after alcohol washing ;

[0096] The ratio of the thiothiamine crude product to ethanol is 1:5.

[0097] The drying time after the alcohol washing is 5 hours, and the temperature is 50°C;

[0098] (2) The crude thiothiamine washed with alcohol and dried was washed with distilled water at 25° C. to remove impurities dissolved in water in the thiothiamine to obtain crude product A;

[0099] The ratio of the crude thiothiamine to distilled water is 1:5.

[0100] The drying time after washing with water is 8 hours, and the temperature is 80°C;

[0101] (3) Mix the crude product A and ethanol at a ratio of 1:60, then reflux and heat up to 80°C until the crude product A is completely dissolved to obtain sol...

Embodiment 3

[0106] A refined method for thiothiamine, said method comprising the following steps:

[0107] (1), first wash the crude thiothiamine with ethanol at 18°C to remove impurities soluble in ethanol in the crude thiothiamine, then filter and dry to obtain the crude thiothiamine after alcohol washing ;

[0108] The ratio of the thiothiamine crude product to ethanol is 1:3.

[0109] The drying time after the alcohol washing is 3 hours, and the temperature is 42°C;

[0110] (2) The crude product of thiothiamine washed with alcohol and dried was washed with distilled water at 18° C. to remove impurities dissolved in water in the thiothiamine to obtain crude product A;

[0111] The ratio of the crude thiothiamine to distilled water is 1:4.

[0112] The drying time after washing with water is 6 hours, and the temperature is 65°C;

[0113] (3) Mix crude product A and ethanol at a ratio of 1:55, then reflux and heat up to 78°C until crude product A is completely dissolved to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com