Automatic transfer switch, dual power automatic transfer switch and manufacturing method thereof

A technology of automatic transfer switch and manufacturing method, applied in the direction of electric switch, emergency power supply arrangement, circuit, etc., can solve the problems of slow transfer time, large product volume, long transfer time, etc., achieve short development cycle, small size, reduce transmission link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

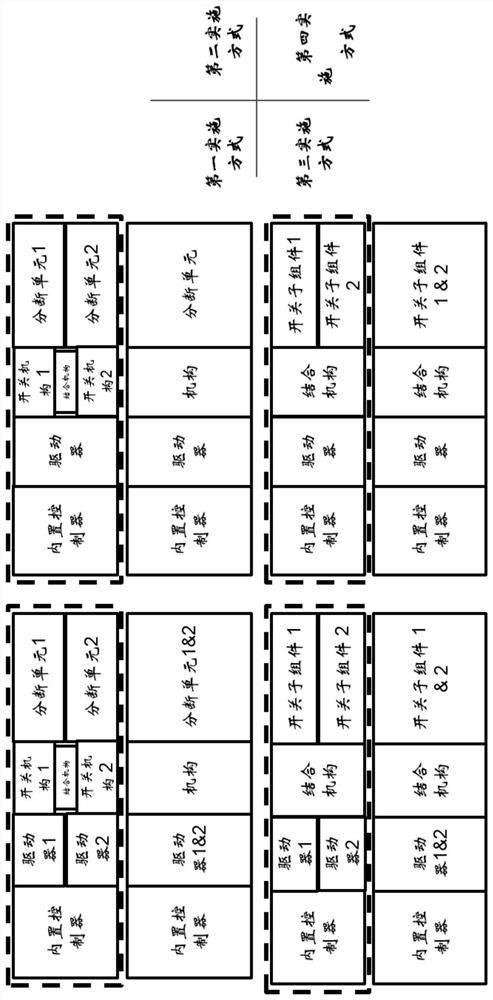

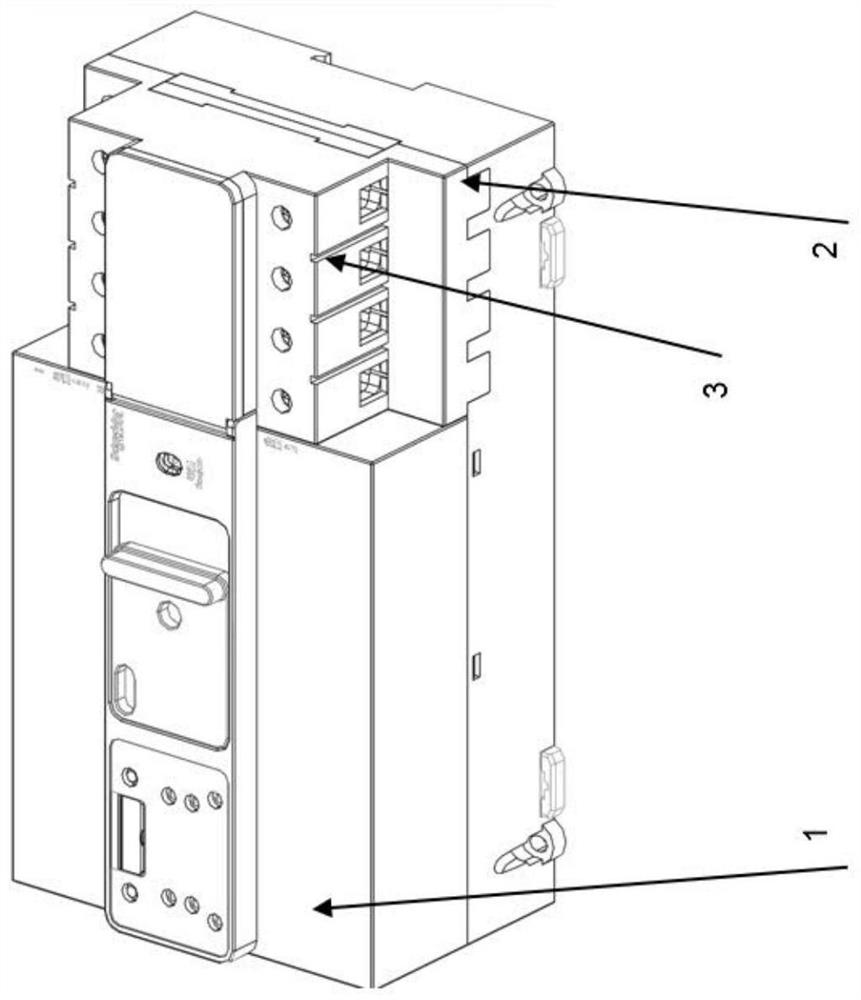

[0070] Figure 2 be Figure 1 Schematic diagram of the first embodiment of the automatic transfer switch shown in; Figure 3 be Figure 2 Exemplary physical diagram of the first embodiment of the automatic transfer switch shown in; Figure 4 be Figure 3 View of the shell removal of the shell of the exemplary physical drawing of the first embodiment of the automatic transfer switch shown in the automatic transfer switch; Figure 5 be Figure 4A local magnified view of the exemplary physical drawing of the shell removal of the first embodiment of the automatic transfer switch shown in the automatic transfer switch.

[0071] from Figure 2 The automatic transfer switch according to the present invention is composed of a first switch module and a second switch module superimposed, the first switch module comprises a first built-in controller, a first driver, a first switching mechanism and a first breaking unit, a second switching module comprising a second built-in controller, a second driv...

no. 2 approach

[0074]Figure 6 Yes, accordingly Figure 1 Schematic diagram of the second embodiment of the automatic transfer switch shown in; Figure 7 Yes, accordingly Figure 6 An exemplary physical view of the second embodiment of the automatic transfer switch shown in the physical diagram. Reference Figure 6 and Figure 7 It can be seen that, according to a second embodiment of the automatic transfer switch of the present invention, the first breaking unit 2 and the second breaking unit 3 are superimposed, the first switching mechanism 6 and the second switching mechanism 7 are superimposed, and the first embodiment is different, the superimposed first switching mechanism 6 and the second switching mechanism 7 are disposed between the superimposed first breaking unit 2 and the second breaking unit 3, Further, the corresponding first driver 4 and the second switch mechanism 7 of the first switch mechanism 4 and the second driver 5 are set at the same level as the first switch mechanism 6 and the...

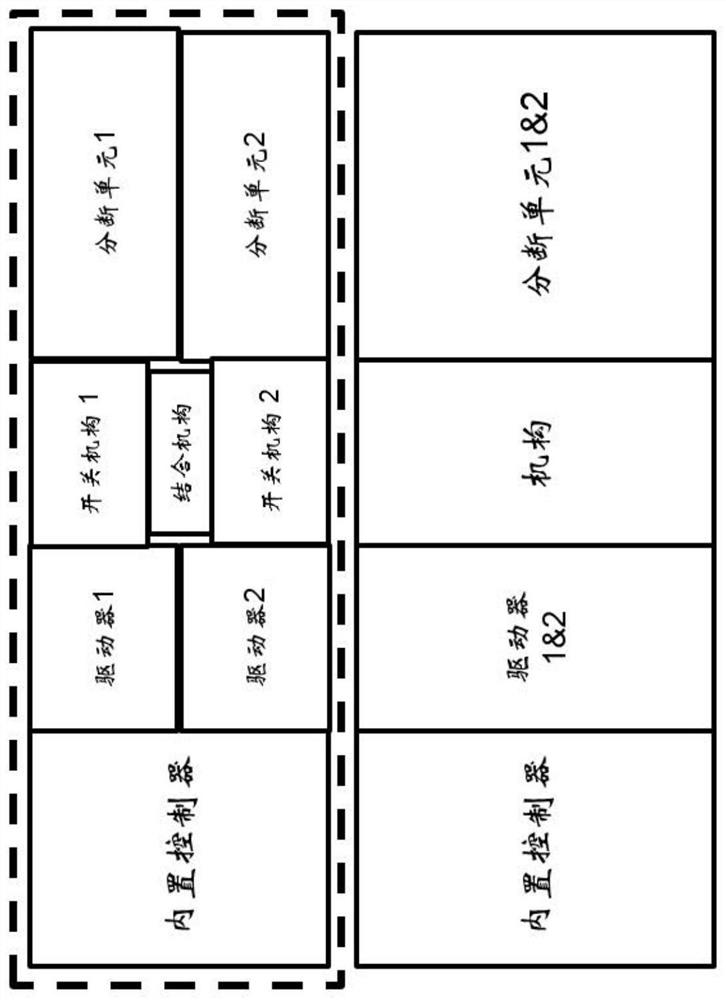

no. 3 approach

[0077] Figure 8 Yes, accordingly Figure 1 Schematic diagram of the third embodiment of the automatic transfer switch shown in; Figure 9 Yes, accordingly Figure 8 An exemplary physical diagram of the third embodiment of the automatic transfer switch shown in. The third embodiment is similar to the first embodiment described above. from Figure 8 and Figure 9It can be seen that the first breaking unit 2 and the second breaking unit 3 are superimposed, the superimposed first switching mechanism and the second switching mechanism and the combined mechanism arranged between the first switching mechanism and the second switching mechanism together constitute an automatic transfer switch mechanism according to the present invention 6,7,9. The difference is that, in this third embodiment of the automatic transfer switch according to the present invention, the first driver and the second driver are replaced by a driver. The mechanism 6,7,9 of the automatic transfer switch and the driver ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com