Soybean screening device for oil pressing

A screening device, soybean technology, applied in the direction of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of heavy workload, cumbersome operation, low efficiency, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

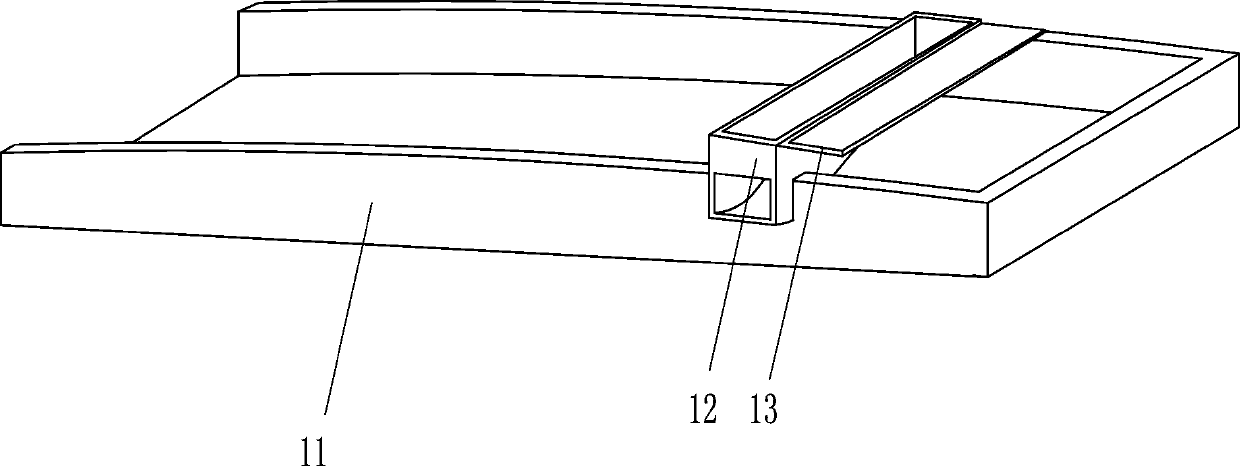

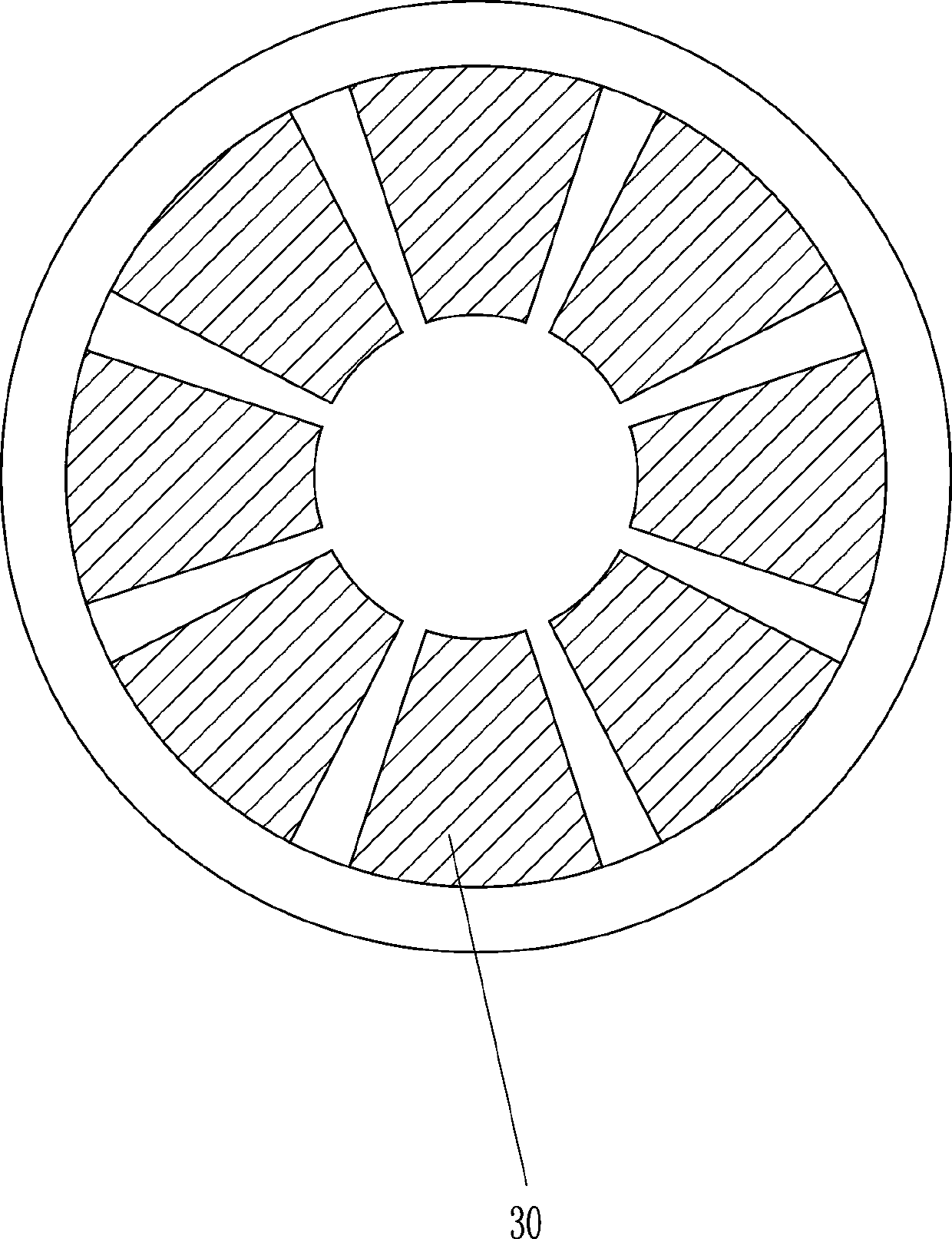

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4 , a soybean screening device for oil pressing, comprising a workbench 1, a mounting plate 2, a lower hopper 3, a valve 4, a first guide sleeve 5, a bracket 6, a second guide sleeve 7, a slide bar 8, a handle 81, a screening Frame 9, opening and closing device 10, square slideway 11, concave slideway 12, arc-shaped cover plate 13, concave-shaped block 14, guide wheel 15, stay cord 16, arc-shaped slideway 17 and slide shaft 18, work The top of the table 1 is provided with a mounting plate 2, and the upper part of the front side of the mounting plate 2 is detachably provided with a lower hopper 3, and the lower hopper 3 is provided with a valve 4, the valve 4 is two, and the left side of the top of the workbench 1 is symmetrically provided with a bracket 6. A second guide sleeve 7 is provided between the two brackets 6, and a first guide sleeve 5 is provided on the mounting plate 2. The first guide sleeve 5 and the ...

Embodiment 2

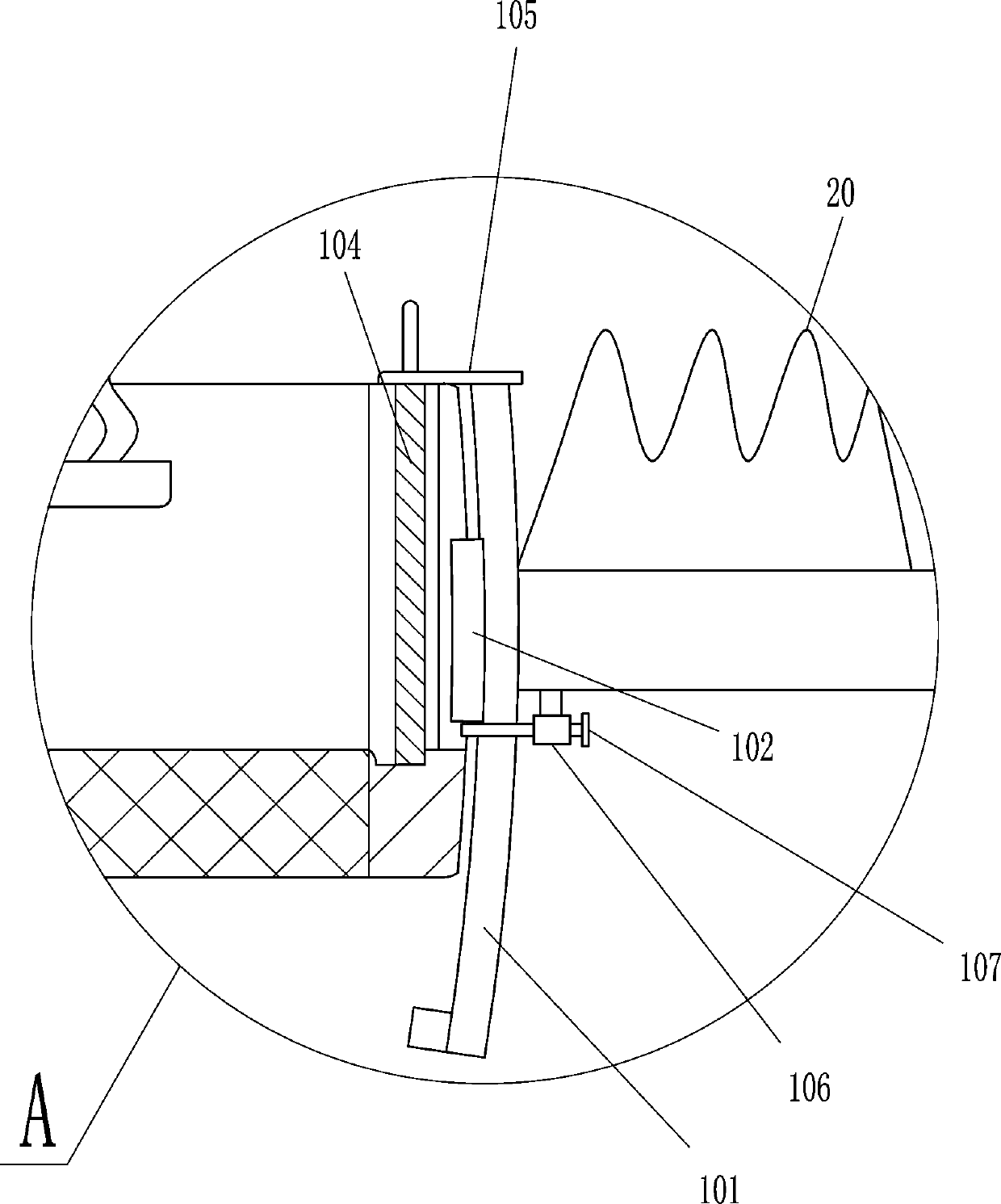

[0023] refer to figure 1 and Figure 5 , on the basis of Embodiment 1, it also includes a fixed block 19 and a first elastic member 20, the top of the first guide sleeve 5 is provided with a fixed block 19, and a first elastic member is provided between the fixed block 19 and the arc-shaped slide rail 101 Part 20, the first elastic part 20 is a compression spring. When the screening frame 9 moves to the right, the first elastic member 20 can play a buffering role. When the pushing resistance increases, the staff pulls the handle 81 to the left. The device has a simple structure and can protect the screening frame 9.

[0024] Also comprise mounting frame 21, toggle wheel 22, gear 23, the 3rd guide sleeve 24, moving rod 25 and tooth bar 26, be provided with the 3rd guide sleeve 24 between two supports 6, slide type on the 3rd guide sleeve 24 A moving rod 25 is provided, one end of the moving rod 25 is connected to the handle 81, the other end of the moving rod 25 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com