Sand box for metal casting

A metal casting and sandbox technology, applied in casting molding equipment, metal processing equipment, mold boxes, etc., can solve the problems of insufficient sandbox connection, damaged bolts, inability to disassemble, etc., to achieve structural strength compliance and improve heat dissipation efficiency , The effect of preventing the phenomenon of lifting the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

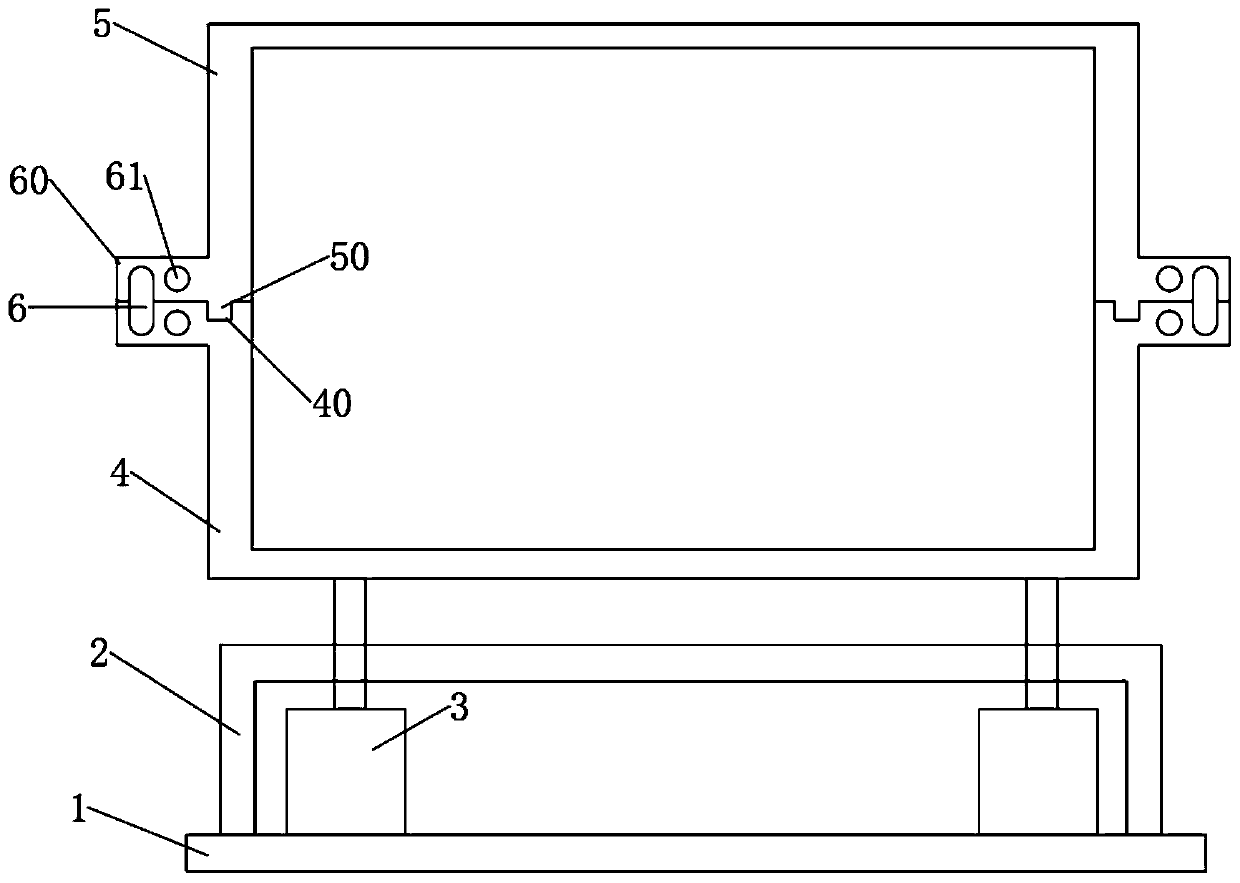

[0026] Such as Figure 1-5 As shown, a sandbox for metal casting includes a base 1 on which a support plate 2 is fixed, the support plate 2 is rectangular in design, the hydraulic column 3 is fixedly connected to the lower casing 4, and the The lower casing 4 is connected with the upper casing 5, and the lower casing 4 and the upper casing 5 are provided with a fixing flange 60 at the junction, and the fixing flange 60 is provided with a fixing hole 61, and the fixing hole 61 A U-shaped collar 6 is plugged in.

[0027] Specifically, a fixing flange 60 is provided at the junction of the upper casing 5 and the lower casing 4, and by setting a fixing hole 61 in the horizontal direction of the fixing flange 60, the U-shaped collar 6 is inserted through the fixing hole 61, so that The upper shell 5 and the lower shell 4 are reliably connected.

[0028] Further, the upper housing 5 is provided with a positioning block 50, and the lower housing 4 is provided with a positioning slot...

Embodiment 2

[0038] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

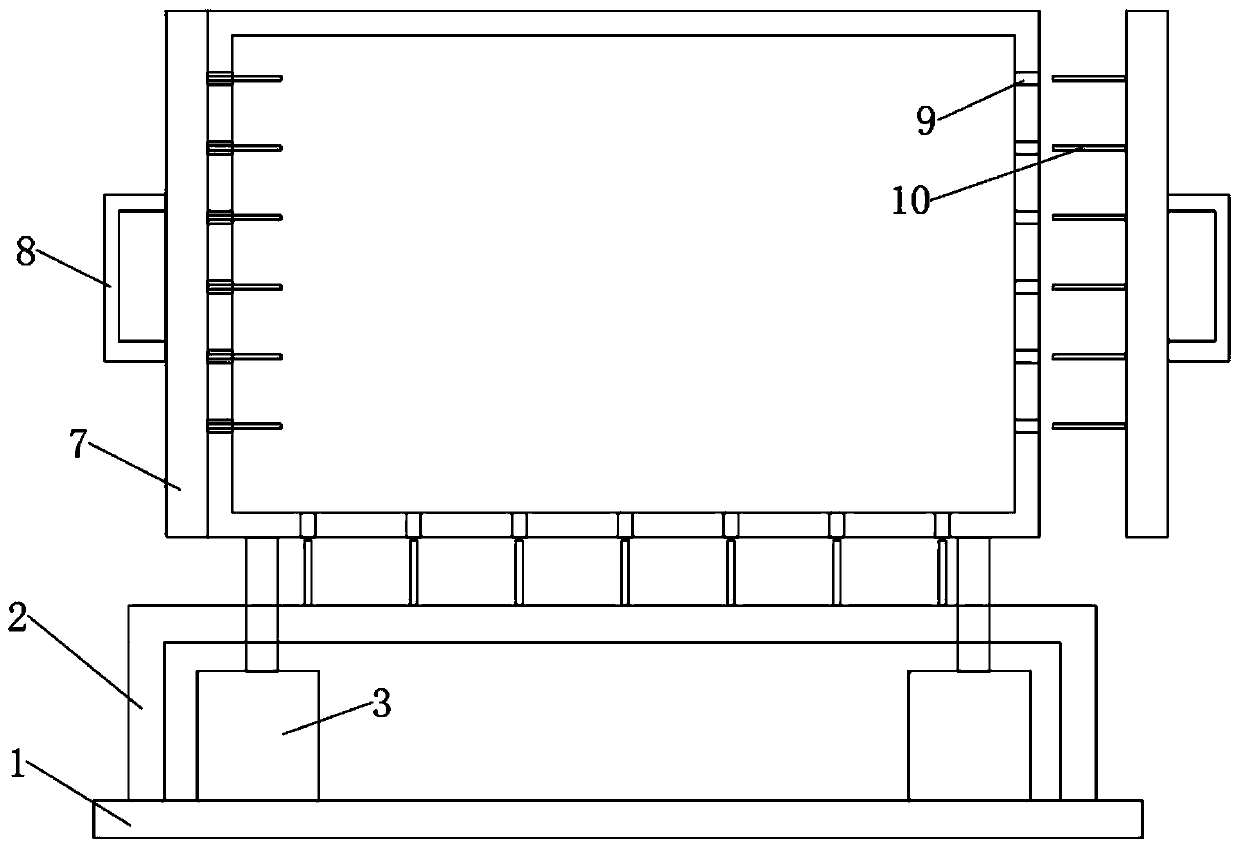

[0039] Such as Figure 1-5 As shown, a sandbox for metal casting includes a base 1, a support plate 2 is fixed on the base 1, the support plate 2 is rectangular in design, hydraulic columns 3 are evenly arranged in the support plate 2, and the The hydraulic column 3 is fixedly connected with the lower casing 4, and the bottom of the lower casing 4 is evenly provided with air holes 9, and the support plate 2 is provided with thin rods 10 at the corresponding positions of the air holes 9, and the lower casing 4 Connected with the upper casing 5, the lower casing 4 and the upper casing 5 are provided with a fixing flange 60 at the joint, and the fixing flange 60 is provided with a fixing hole 61, and the fixing hole 61 is inserted with a U-shaped collar 6.

[0040] Specifically, the upper shell 5 and the lower shell 4 are placed on the support plate 2 in the initial st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com