Detachable stapler arranging plate structure

A technology for a stapler and a finishing board, which is applied to staple U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problems affecting the aesthetics and binding firmness, inconvenient disassembly of the stapler and the finishing board, and the distance between binding points. It is not easy to grasp and other problems, so as to achieve the effect of improving aesthetics, quick disassembly and assembly, and even binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

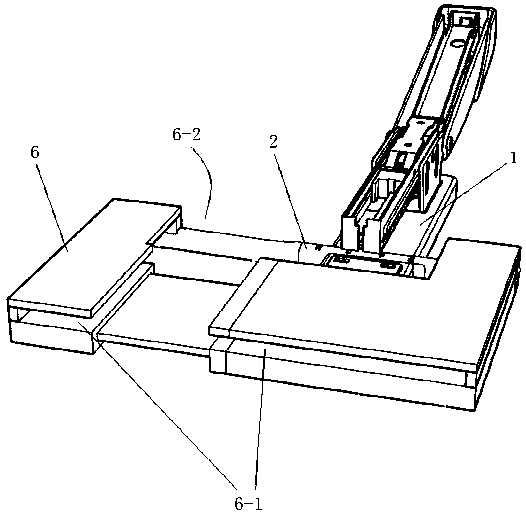

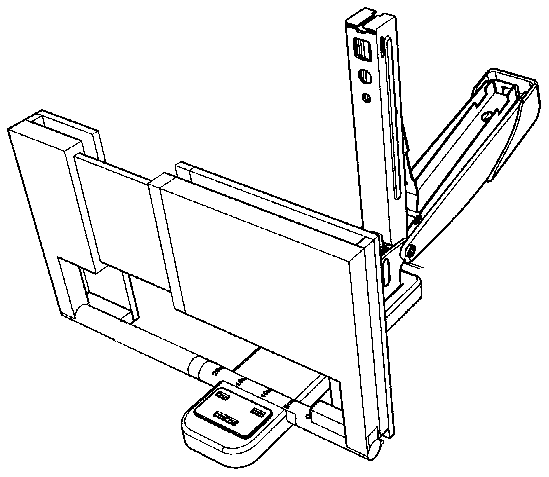

[0021] like figure 1 and figure 2 As shown, a detachable stapler finishing board structure includes a stapler 1 and a finishing board 6;

[0022] The binding end of the stapler 1 is provided with a sliding hole 1-1 perpendicular to the stapler 1; the upper side of the sliding hole 1-1 intersects with the upper surface connected to the binding end, and the upper side of the sliding hole 1-1 forms an open indication slot 1-2;

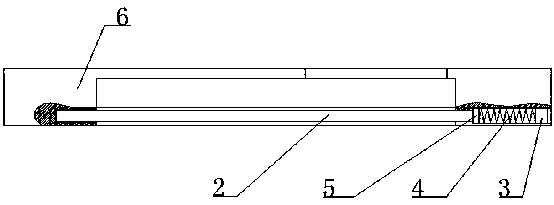

[0023] Have the finishing groove 6-1 that is used to place paper on the finishing board 6, combine figure 2 As shown, the upper side of the finishing slot 6-1 is open for putting in paper; the binding slot 6-2 is under the finishing plate 6, the binding slot 6-2 communicates with the finishing slot 6-1, and the binding end of the stapler 1 At the position of binding slot 6-2;

[0024] The identification shaft 2 is installed between the two ends of the binding groove 6-2, and the identification shaft 2 is marked with a scale. The identification shaf...

Embodiment 2

[0034] On the basis of the first embodiment above, combined with Figure 4 as shown,

[0035] In order to realize the fast disassembly and assembly of the stapler 1 and the finishing plate 6, the specific structure of the sliding hole 1-1 is:

[0036] Sliding hole 1-1 is divided into fixed part 7 and sliding part 8 from the middle; ; The spring II 9 for pushing the sliding part 8 to the fixed part 7 is connected to the back side of the sliding part 8 .

[0037] Preferably: the binding end of the stapler 1 is provided with a chute 1-3, and the side wall of the chute is provided with a bar-shaped guide groove 1-4; There is a strip guide plate 8-1 that cooperates with the strip guide groove 1-4.

[0038] when using it,

[0039] Slide the sliding part 8 to press against the spring Ⅱ 9, so that the indication groove 1-2 is opened and widened;

[0040] Then, put the identification shaft 2 into the sliding hole 1-1 at the fixed part 7;

[0041] Finally, the sliding part 8 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com